Labor-saving stapler

A stapler and staple technology, which is applied to staple staple tools, manufacturing tools, etc., can solve the problems of large force, staple bending, user's hand fatigue and pain, etc., and achieves convenient needle installation and design Reasonable, good binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

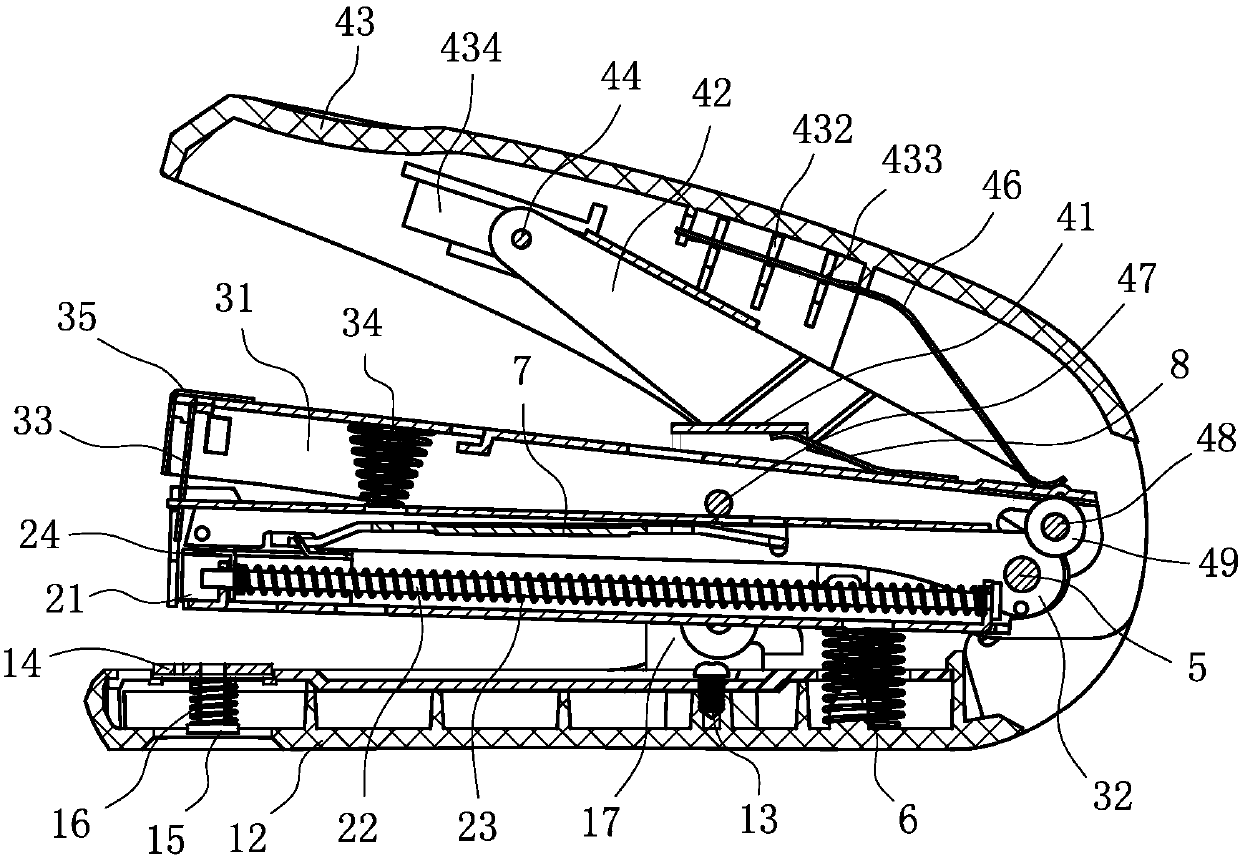

[0028] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

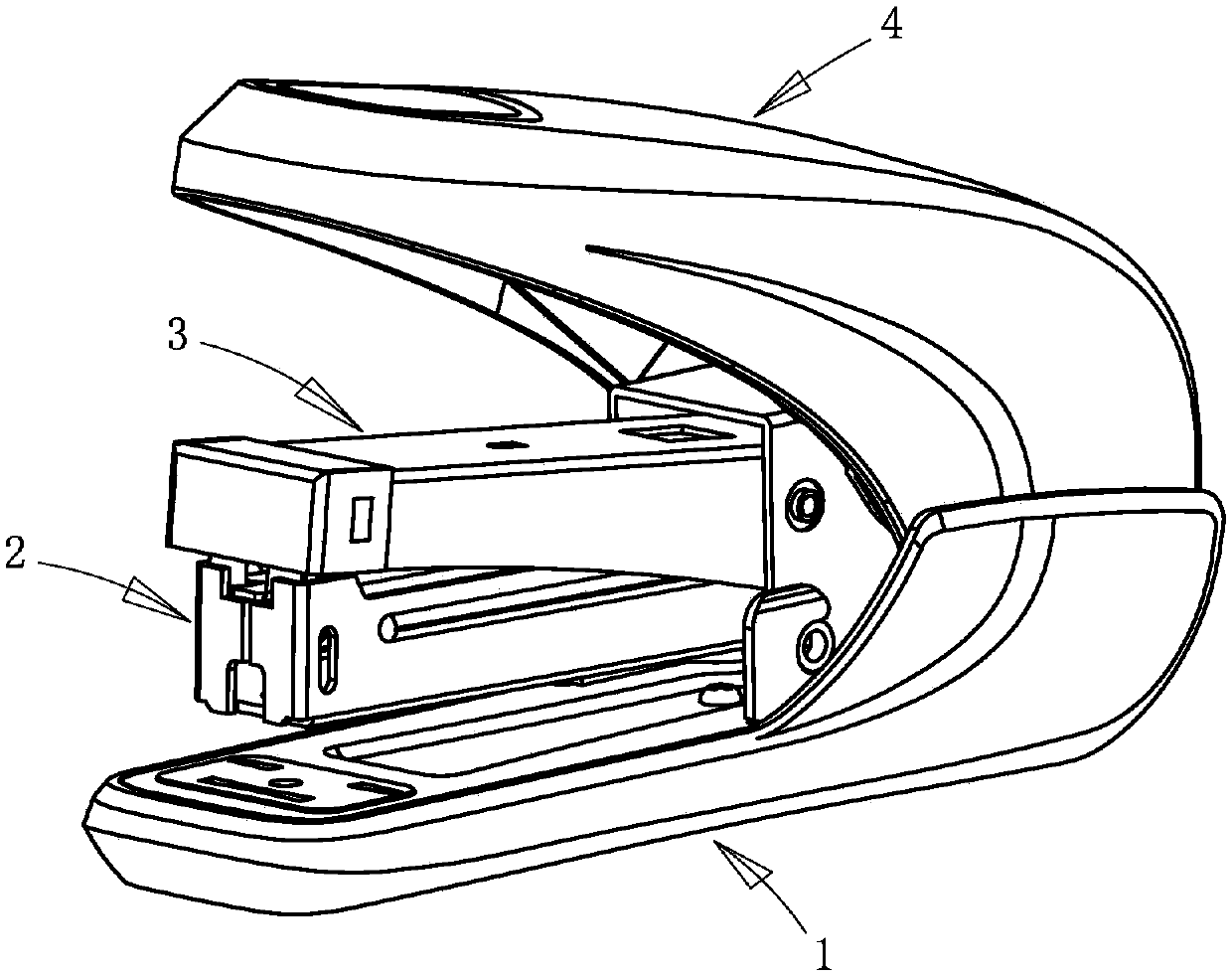

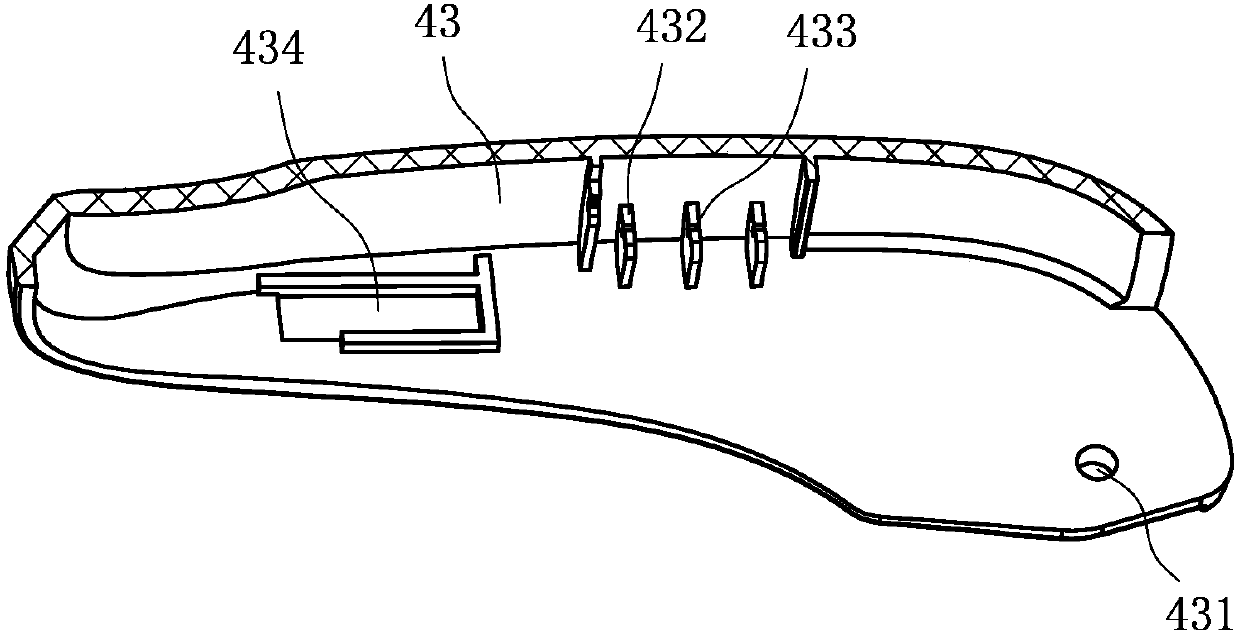

[0029] see Figure 1 to Figure 6 As shown, the labor-saving stapler provided by the present invention includes a base assembly 1, a binding assembly 2, a staple assembly 3, and a labor-saving assembly 4. The base assembly 1 includes a metal base 11, a plastic shell base 12. The two ends of the metal base 11 are buckled and connected with the molded case base 12, and fastening screws 13 are fastened in the middle and rear of the molded case base 12; The lower groove nail post 15 with the lower groove spring 16 is riveted on the groove 14; the two sides of the tail of the metal base 11 are provided with corresponding coaxial pin holes.

[0030] The binding assembly 2 includes a strip-shaped binding box 21, and a long shaft 22 is fastened in the needle box 21 along the length direction of the needle box, and a push stapler is set on the shaft 22....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com