Combined centering type blade mounting angle measurement device

An angle measurement device and blade installation technology, which is applied in angle/taper measurement and other directions, can solve the problems of lack of precise positioning of the measurement device, insufficient accuracy of measurement results, and insufficient rigidity of rods, etc., to achieve simple structure, easy control of precision, and data precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

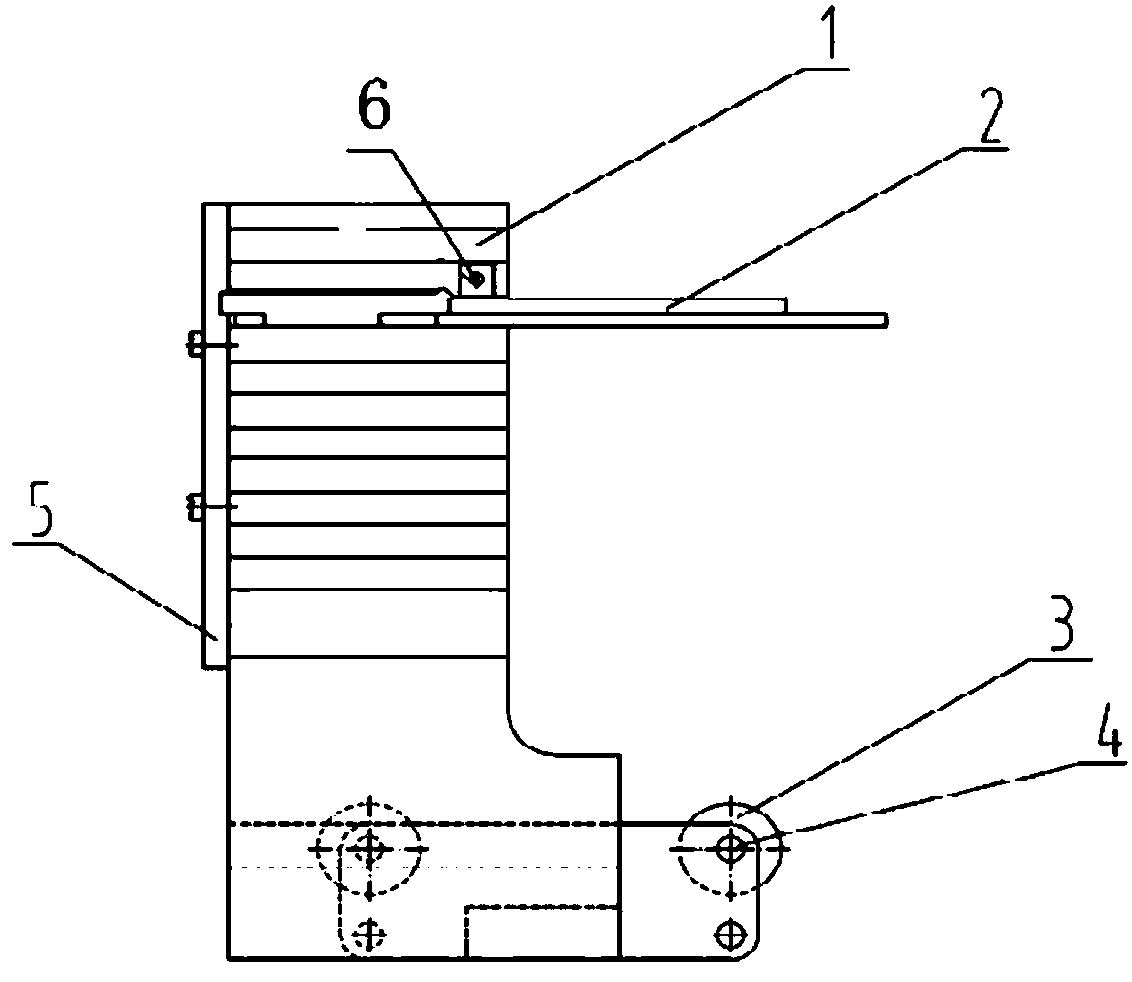

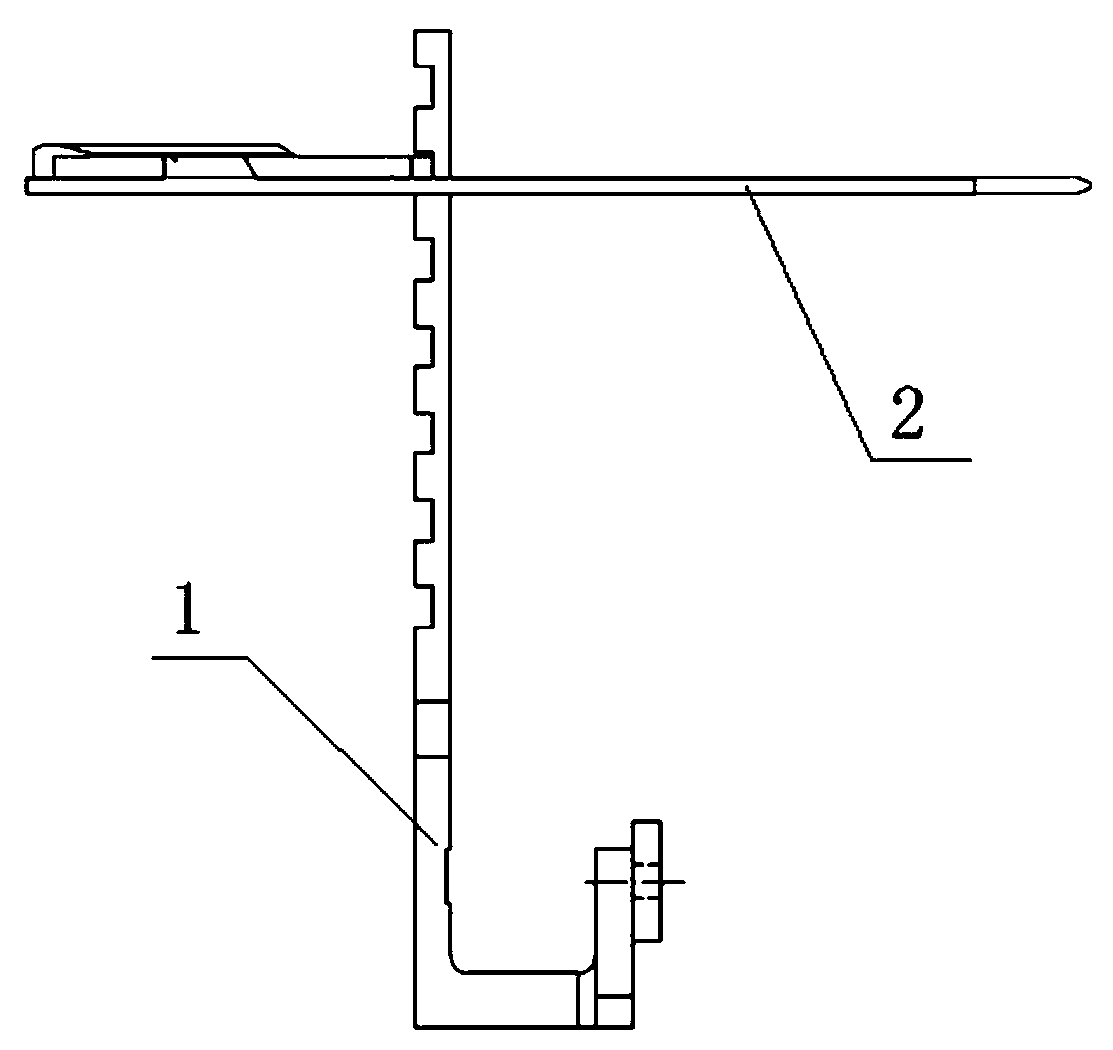

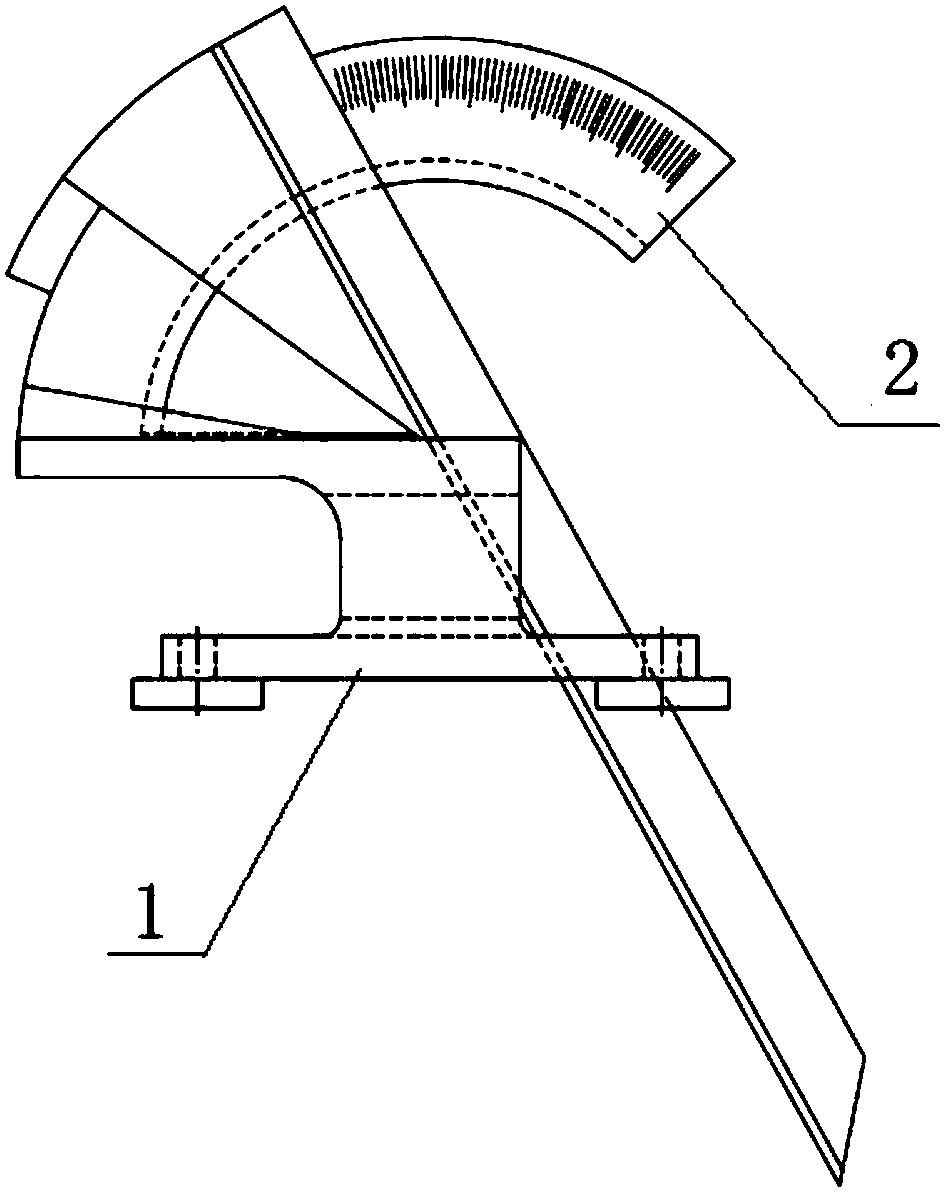

[0023] This embodiment is a combined centering type blade installation angle measuring device. Its working principle is: set a group of support rollers 3 for supporting and positioning the inner ring or outer ring of the measured blade 7, so that the measured blade 7 has automatic positioning. Cardiac Function. Then arrange the angle gauge 2 on the corresponding part of the tested blade 7, so that the rotation center of the angle gauge 2 passes through the radial centerline of the inner ring or outer ring of the tested blade 7 vertically, and at the same time, the measuring section of the tested blade can be accurately positioned. During measurement, the blade under test 7 is slid along the supporting arc surface formed by the support roller 3, and the relative position of the angle gauge 2 and the bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com