Fast-cooling strainer cup

A technology of cup drain and rapid cooling, applied in the field of rapid cooling cup drain, can solve the problems of high pressure, small cooling range, and low practicability, and achieve the effect of convenient use and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

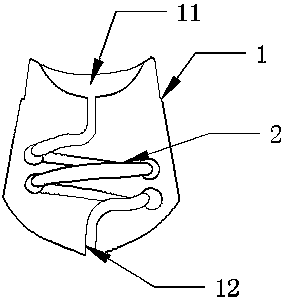

[0014] see figure 1 Shown is a schematic structural view of a preferred embodiment of the present invention.

[0015] The present invention is a quick-cooling cup drain, which mainly includes a cup body 1. The cup body 1 is a cavity structure, and a spiral conduit 2 is arranged in the cavity structure, extending from the cup mouth 11 to the cup bottom 12, the cup mouth 11 and the cup bottom. The helical conduit connection at the bottom 12 is an opening. The cup mouth 11 is sealed in a conical shape, and the apex of the cone is the opening of the helical conduit at the cup mouth 11 . The cup bottom 12 is conical, and the apex of the cone is the opening of the helical conduit at the cup bottom 12 . The inside of the cavity structure of the cup body 1 is refrigerated liquid. When in use, the liquid is poured from the mouth of the cup, the liquid flows out through the spiral conduit, and through the instant cooling of the freezing liquid, the liquid also retains the original fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com