High-temperature-resistant tennis wall

A high temperature resistant, tennis ball technology, applied in the direction of rackets, space-saving games, sports accessories, etc., can solve the problems of weak fixing strength, wall falling off, reducing the application effect, etc., to achieve strong protection, prolong service life, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

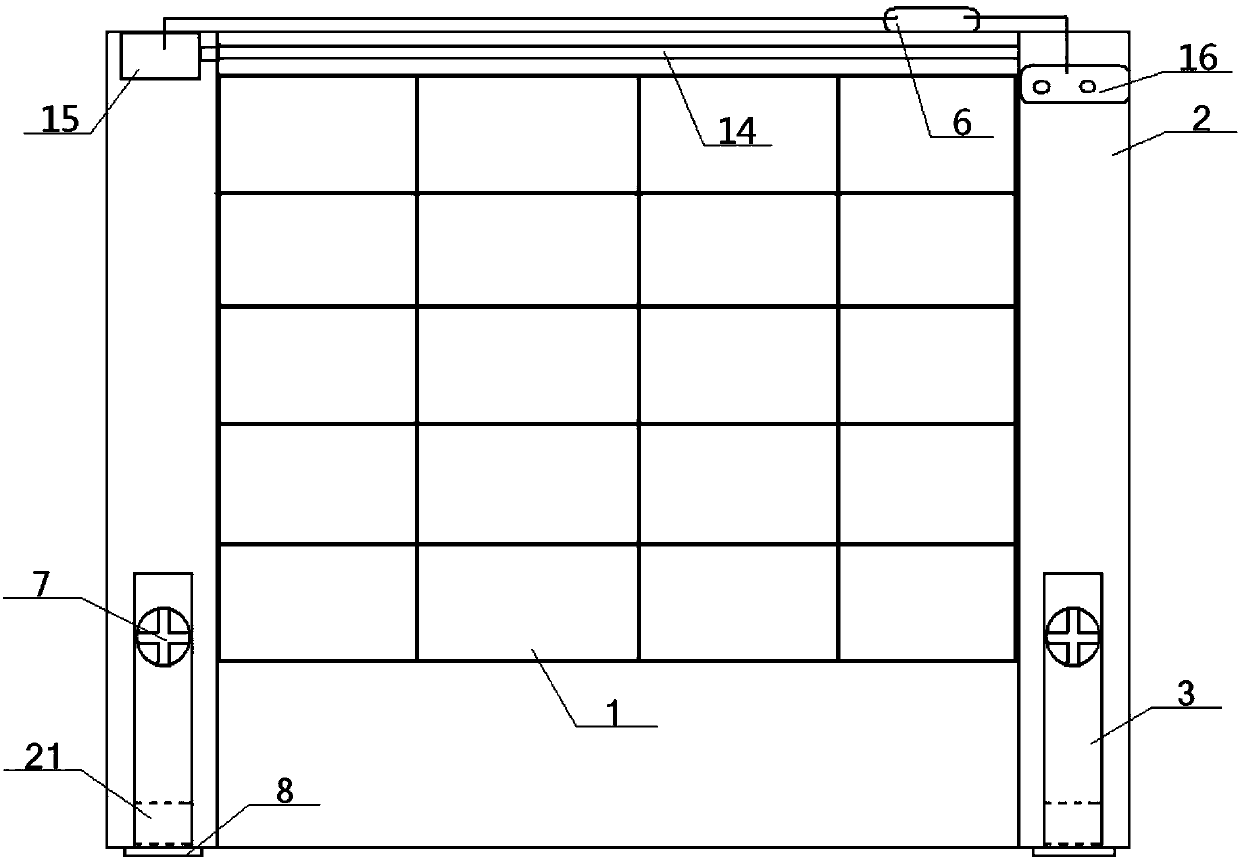

[0051] See figure 1 - Figure 8 , A high temperature resistant tennis wall, comprising a wall 1 and two supporting and fixing columns 2, the left and right sides of the wall 1 are respectively connected to the inner side of a supporting and fixing column 2; the top of the wall 1 A roller blind device 14 is provided. The drive shaft of the roller blind device 14 is connected to the output end of the drive motor 15. The power input end of the drive motor 15 is electrically connected to the power supply 16 through the temperature controller 6, and the drive motor 15 , The temperature controller 6, the power supply 16 are all set on the top of the roller blind device 14;

[0052] The temperature controller 6 includes a metal housing 61, an input power line 62, an output power line 63, an insulating plate 64 and a horizontal wax strip 65. One end of the input power line 62 is connected to the drive motor 15 circuit, and the input power line 62 The other end passes through the left wa...

Embodiment 2

[0055] The basic content is the same as Example 1, the difference is:

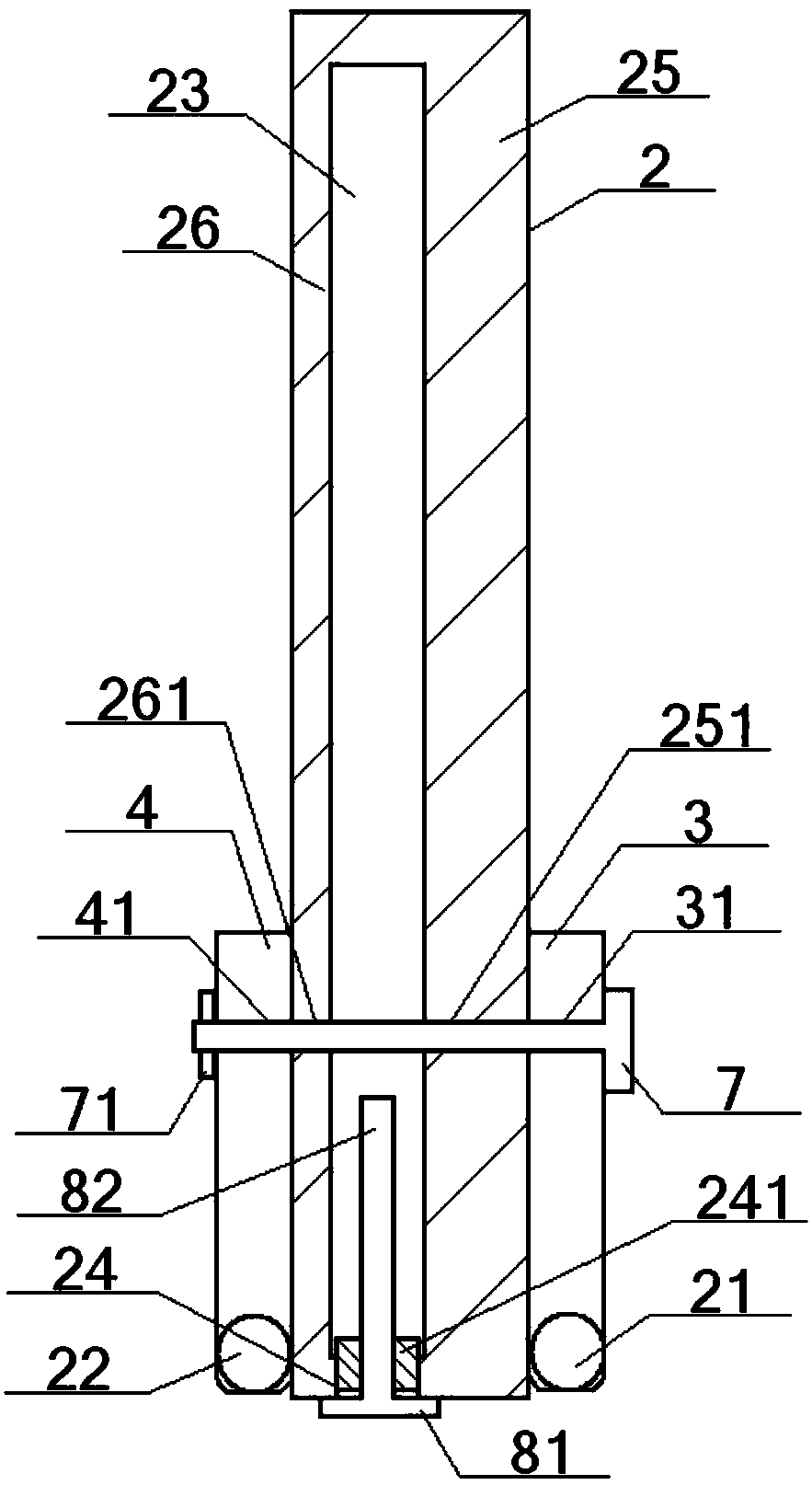

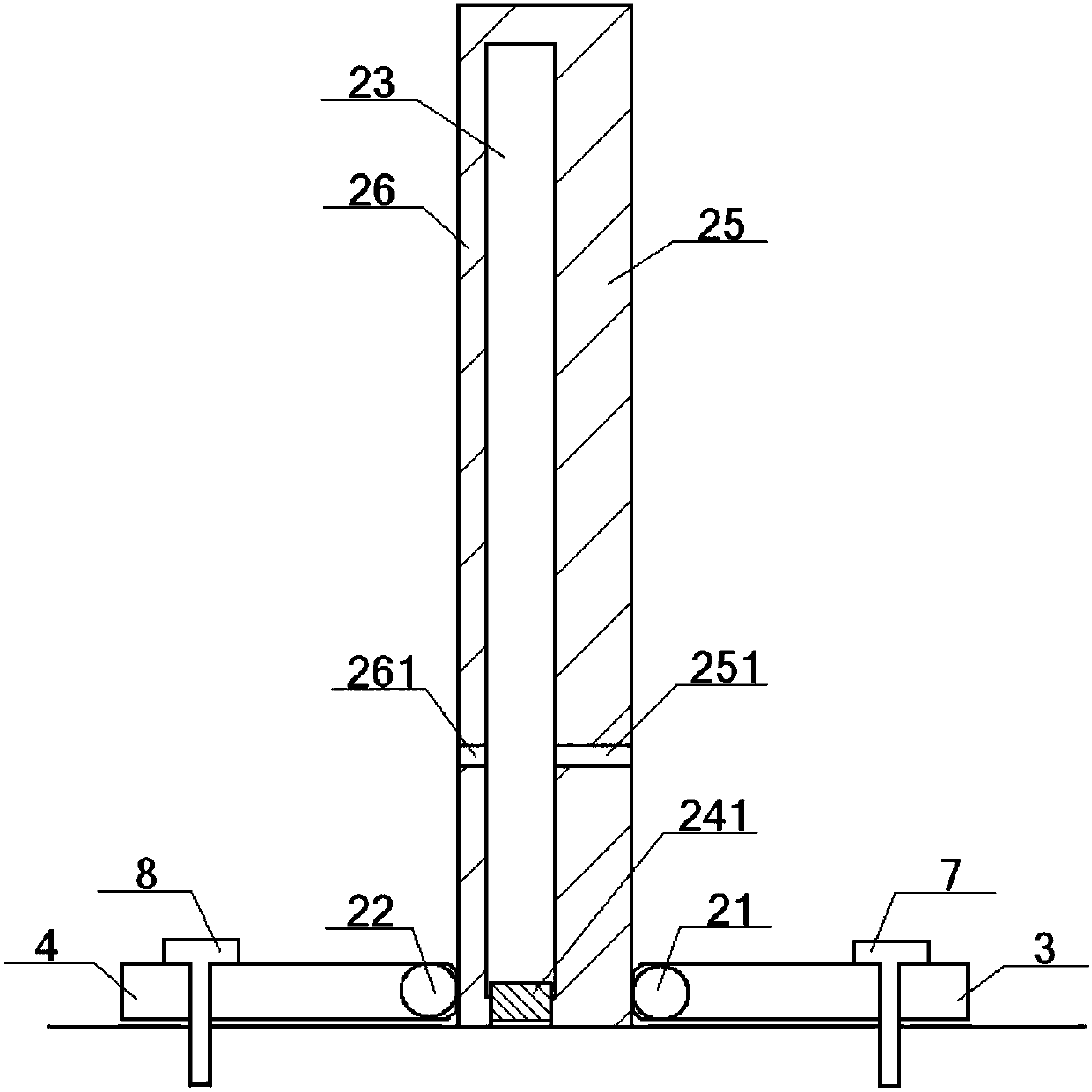

[0056] A hollow cavity 23 is opened inside the supporting and fixing column 2, and the bottom of the hollow cavity 23 is in communication with a closed opening 24 opened at the bottom of the supporting and fixing column 2. The closed opening 24 is inlaid with a closing plug 241, and the inside of the closing plug 241 is connected with The second fixing bolt 8 is threaded, the bolt head 81 of the second fixing bolt 8 is flush with the bottom of the supporting fixing column 2, the bolt head 81 is connected to one end of the bolt column 82, and the other end of the bolt column 82 passes through in turn The sealing port 24 and the sealing plug 241 extend to the inside of the hollow cavity 23; the positions on the front and rear sides of the hollow cavity 23 on the supporting and fixing column 2 are the front column 25 and the rear column 26, respectively. A front wall hole 251 is opened on the 25, and a rear wall...

Embodiment 3

[0059] The basic content is the same as in Example 2, the difference is:

[0060] The front rotation support shaft 3 is provided with two front fixed holes 32 at a location between the front fixed hole 31 and the front rotation shaft 21, and the rear rotation support shaft 4 is located at the rear fixed hole 41 and the rear rotation shaft 22. There are two rear fixed holes 42 in the space between them; the front oblique column 5 and the rear oblique column 53 are placed in the hollow cavity 23; the bottom of the front oblique column 5 is provided with a front corresponding to the two front fixed holes 32 The bottom fixing hole 51, the top of the front inclined column 5 is provided with a front top fixing hole 52 corresponding to the front wall hole 251; the bottom of the rear inclined column 53 is provided with a rear bottom fixing hole corresponding to the rear two fixing holes 42 54. The top of the rear inclined column 53 is provided with a rear roof fixing hole 55 correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com