Round bearing wrench for numerical control tools

A bearing wrench, circular technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

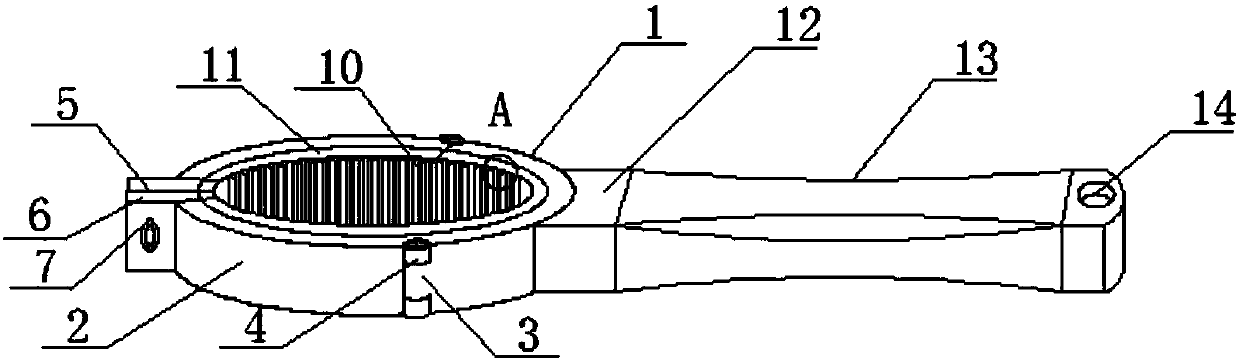

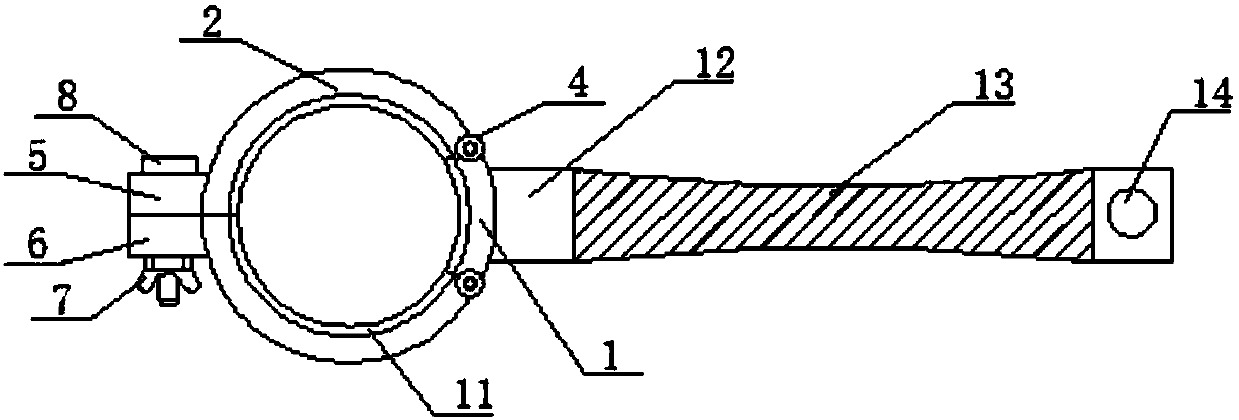

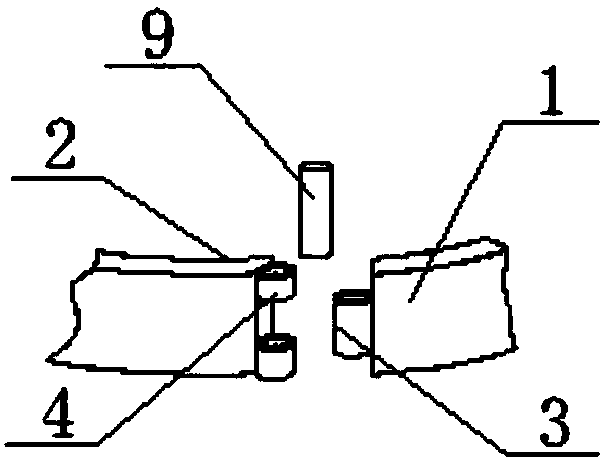

[0023] see figure 1 with figure 2 As shown, a circular bearing wrench for numerically controlled cutting tools includes a fixed ring 1, a movable ring 2 and a clip 10, a connecting buckle 3 is arranged on both sides of the fixed ring 1, a connecting ring 4 is arranged on one side of the movable ring 2, and the connecting buckle 3 and the The connecting ring 4 cooperates with each other, and the connecting buckle 3 and the connecting ring 4 are connected by the pivot pin 9, so that the fixed ring 1 and the movable ring 2 can be flexibly connected, so that the movable ring 2 can freely expand the angle of one end in the horizontal direction, and the movable ring 2 One side is respectively connected with the first connecting block 5 and the second connecting block 6, the first connecting block 5 is connected with the connecting bolt 8, the connecting bolt 8 is connected with the knob nut 7, and the connecting bolt 8 runs through the first connecting block 5 and the second connec...

Embodiment 2

[0025] In addition, refer to Figure 2-Figure 6 , based on the above embodiment, let the fixed ring 1 and the movable ring 2 on both sides form a circular wrench, the fixed ring 1 and the movable ring 2 on both sides are movably connected, and the movable ring 2 can rotate freely in the horizontal direction, The device can be conveniently clamped to the bearing, and can be applied to various types of bearings. The connecting buckle 3 on both sides of the fixed ring 1 is set in the middle position, and the side of the movable ring 2 is provided with a symmetrical connecting ring 4. The groove formed by the connecting ring 4 Cooperate with the connecting buckle 3, the connecting buckle 3 and the connecting ring 4 are all provided with holes matched with the shaft pin 9, so that the fixed ring 1 and the movable ring 2 can rotate freely and are firmly connected, and the first connection on the movable ring 2 The block 5 and the second connecting block 6 are all provided with holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com