An injection mold with adjustable glue feed

A technology of injection mold and glue feeding amount, which is applied in the field of injection molding molds, can solve the problems of quality, processing efficiency, single adjustment of glue feeding amount, pressure and glue feeding amount inconsistency, and achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

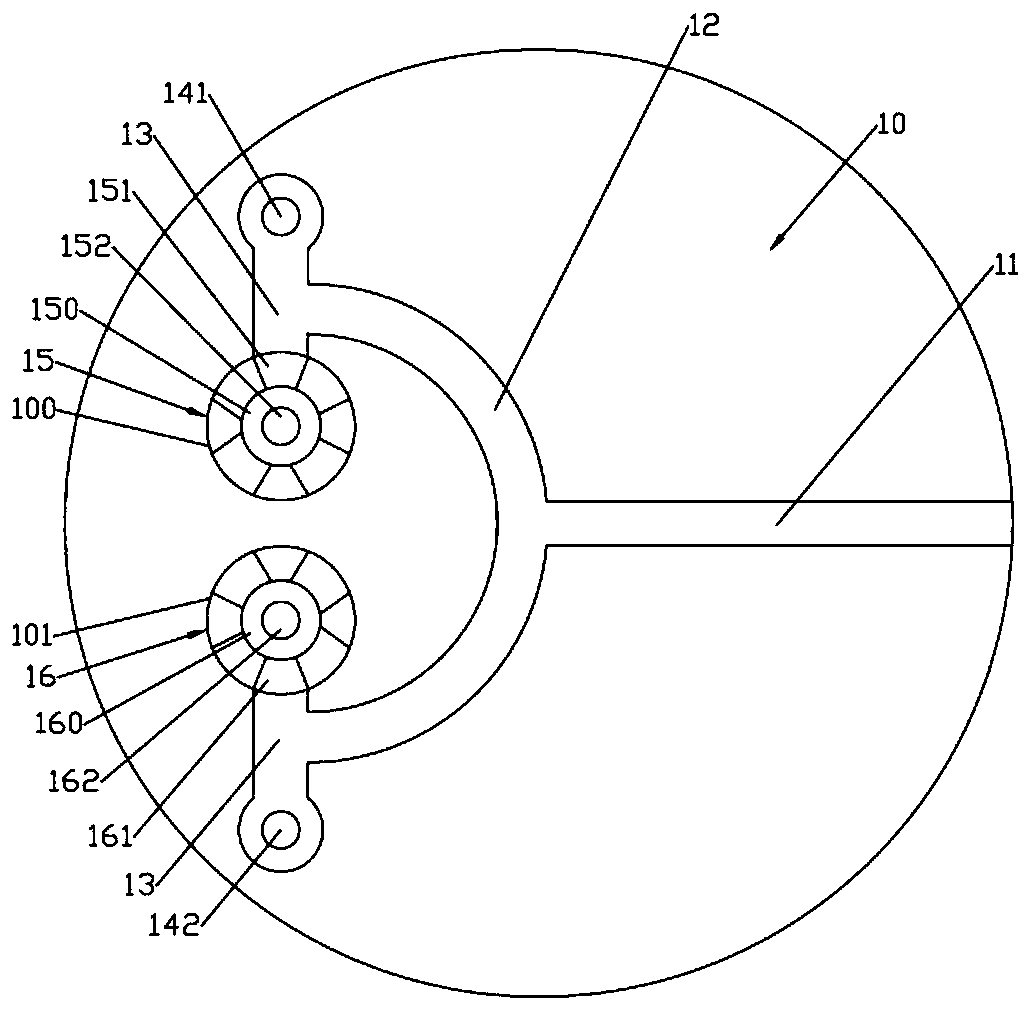

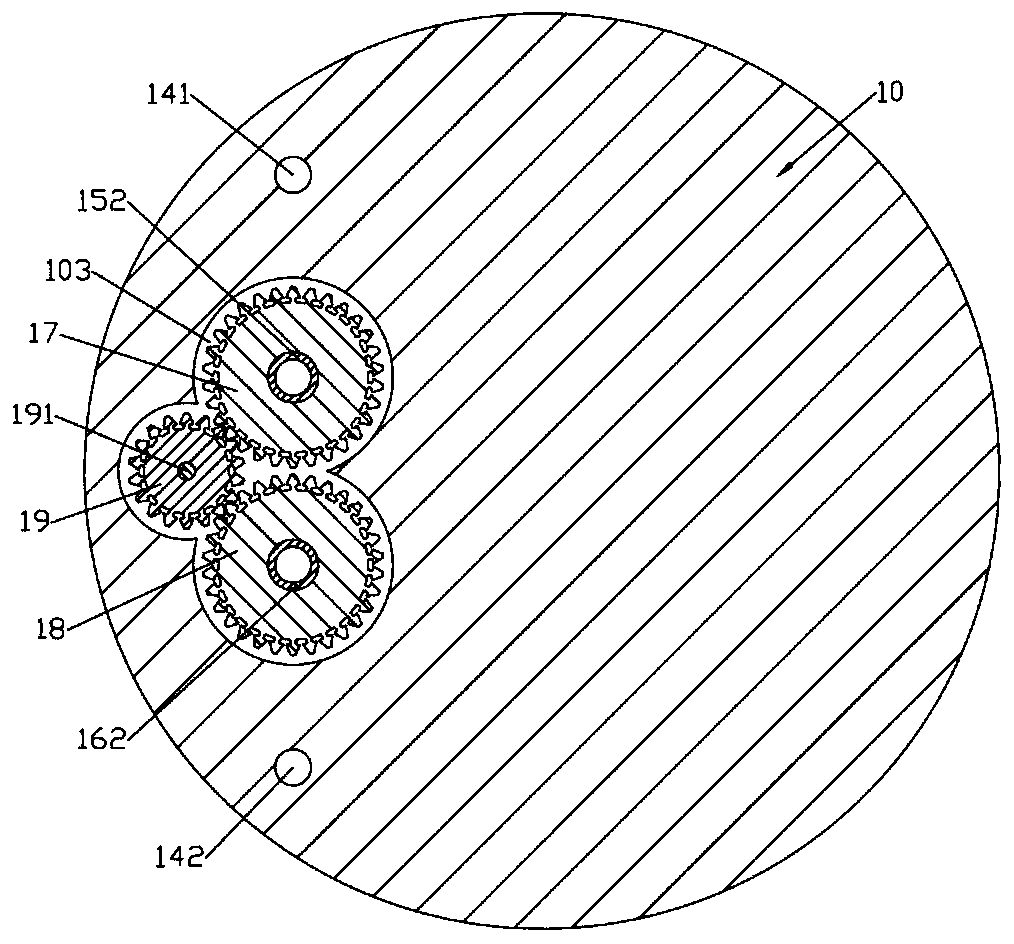

[0013] Such as figure 1 As shown, an injection mold with adjustable glue feed includes a mold body 10; the surface of the mold body 10 is formed with a main channel 11 arranged left and right; the left end of the main channel 11 is connected with a central arc-shaped flow channel 12; the center arc-shaped The front end and the rear end of the runner 12 are respectively connected with a runner 13; the front end of the runner 13 on the front side is connected with a first branch runner 141 communicating with the molding cavity of the mold body 10; the rear end of the runner 13 on the rear side is connected to There is a second branch channel 142 communicating with the molding cavity of the mold body 10; the left side of the surface of the mold body 10 is formed with a cylindrical groove-shaped front adjustment groove 100 and a rear adjustment groove 101; the front adjustment groove 100 and the rear adjustment groove 101 are front and rear Symmetrically arranged; the front adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com