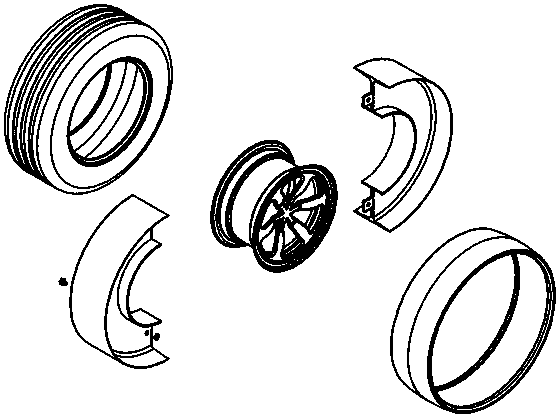

Two combined semi-circular aluminum alloy hub sleeve rings mounted on hub

A technology of aluminum alloy wheels and wheels, which is applied to tire parts, transportation and packaging, vehicle parts, etc., can solve the problems of broken tires, car crashes, injuries, etc., and achieve the effect of simple structure and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

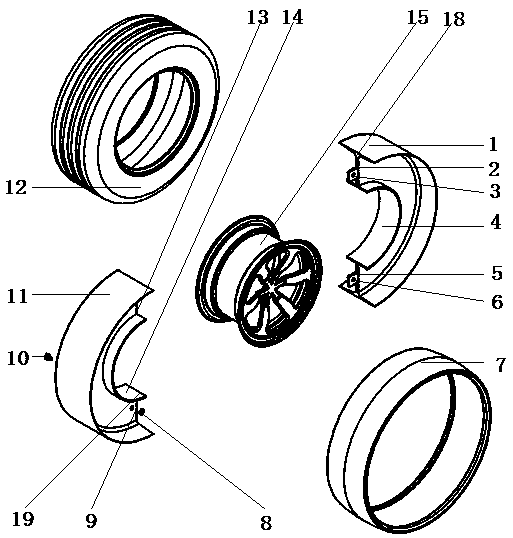

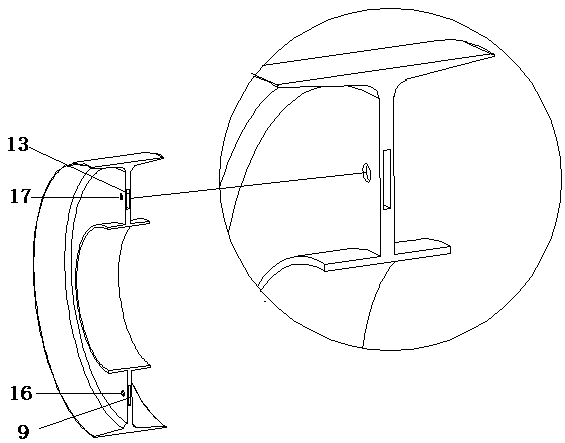

[0021] Example: refer to figure 1 As shown, the feature of the two semicircular fit aluminum alloy wheel hub rings installed on the wheel hub is: on the inner circular surface B of the wheel hub ring B, there are grooves A and groove B, and the groove A is made with Screw hole C, groove B is made with screw hole D above.

[0022] The feature of the two-half-circle fit aluminum alloy wheel hub collar installed on the wheel hub is: on the inner circular surface A of the hub collar A, there are plugs A and plugs B, on the plug A there are screw holes A, the plugs Screw hole B is made on B.

[0023] The features of the two semi-circular composite aluminum alloy wheel hub rings installed on the wheel hub are: the hub ring A and the wheel hub ring B are assembled together through the outer circular surface of the wheel hub 15, the plug A is installed inside the groove B, and the plug B is installed inside groove A.

[0024] The features of the two-half-circle composite aluminum a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com