Reinforcing spinning wheel arch lining

An arch, wheel technology, applied in vehicle components, superstructure sub-assemblies, transportation and packaging, etc., can solve problems such as lack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

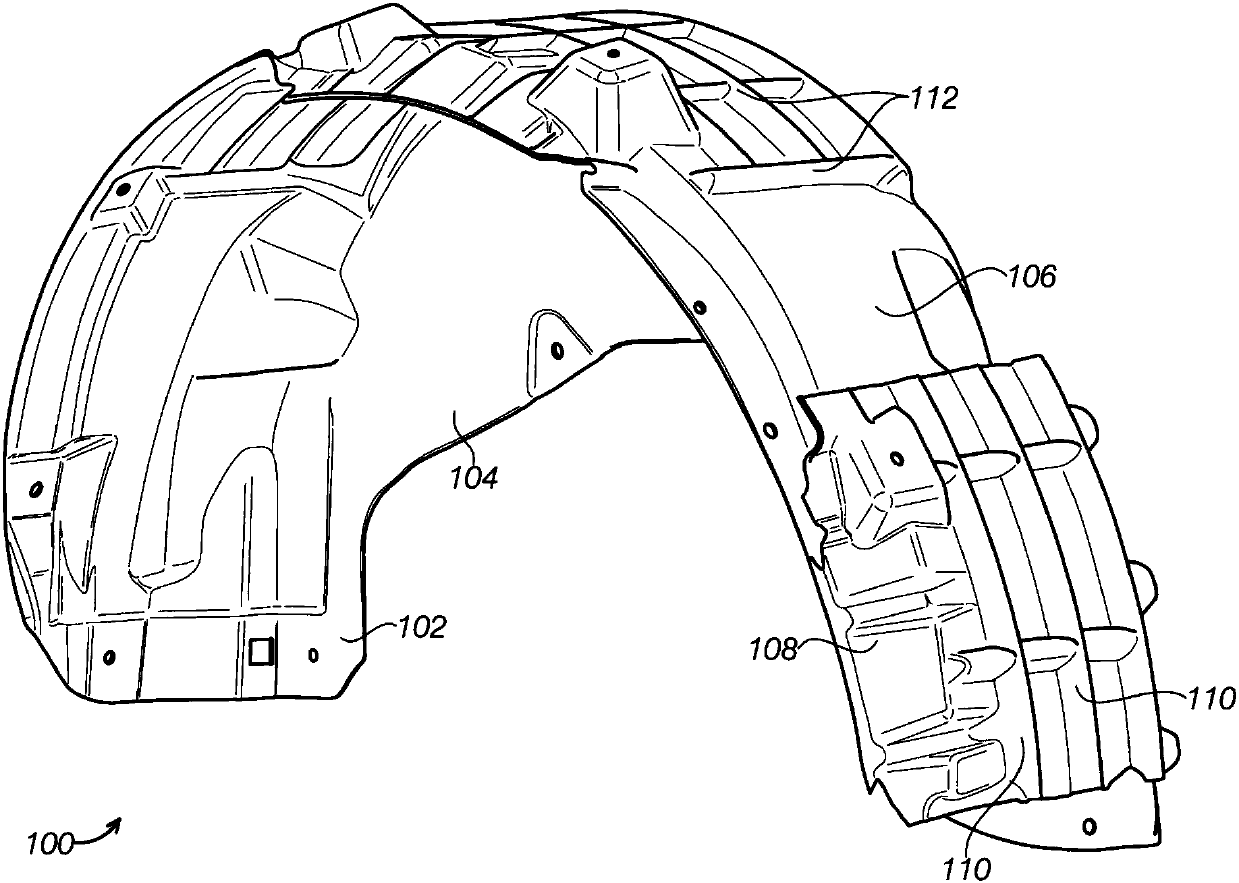

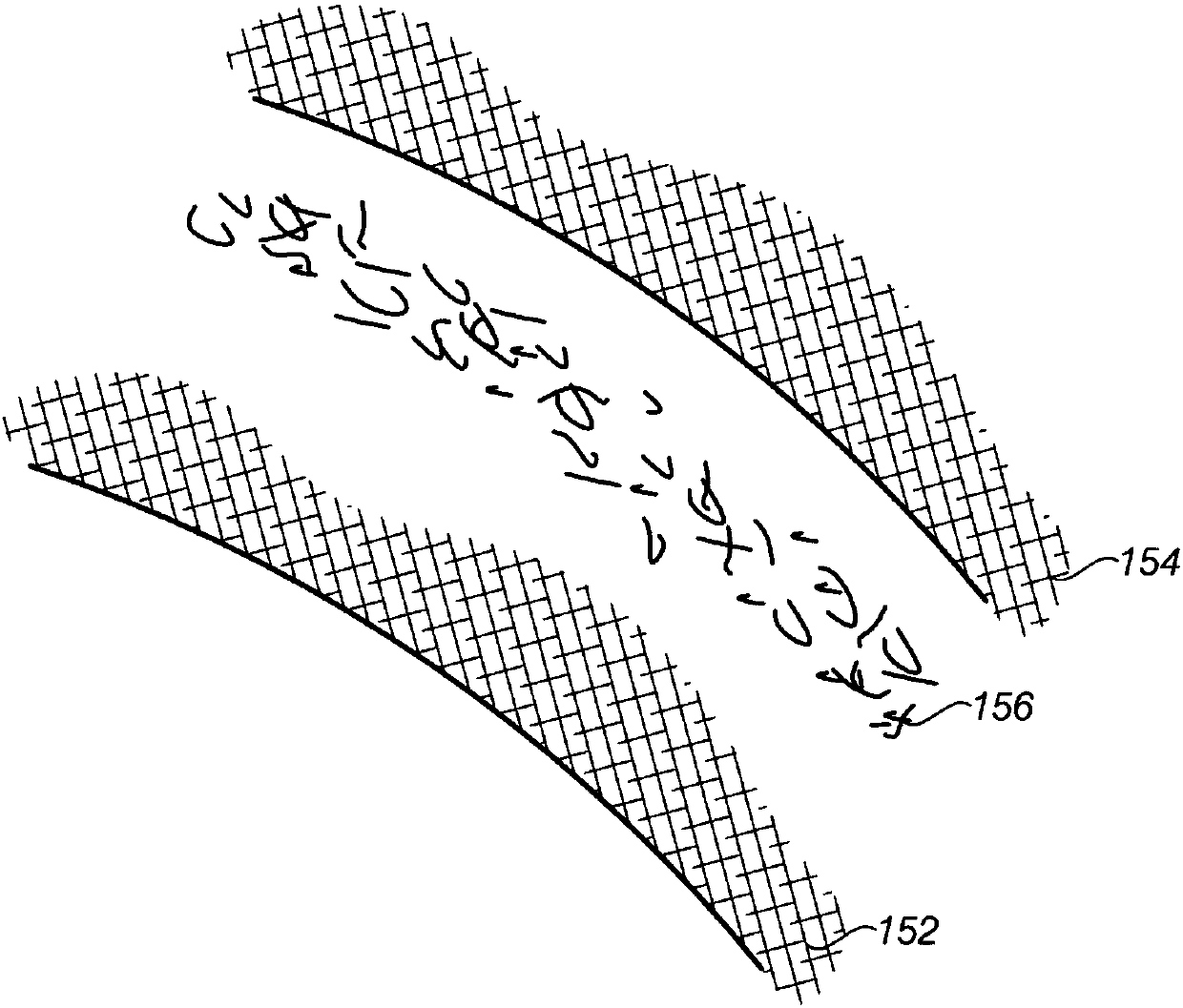

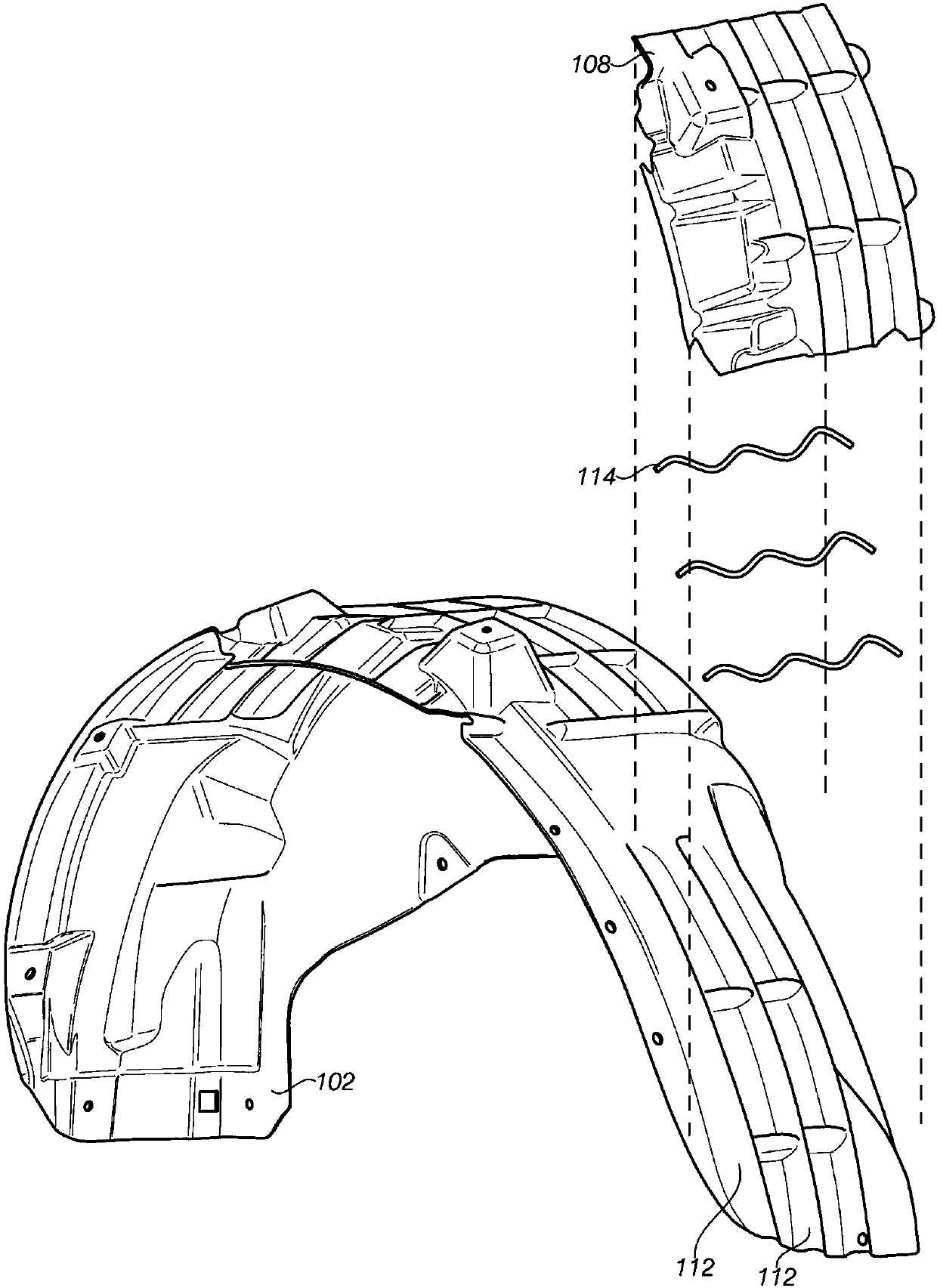

[0033] The disclosed reinforced textile wheel arch liner will be better understood by reading the following detailed description in conjunction with the accompanying drawings. The detailed description and drawings provided are merely examples of the various inventions described herein. Those skilled in the art will appreciate that the disclosed examples may be altered, modified and altered without departing from the scope of the invention described herein. Many variations are contemplated for various applications and design considerations, however, not every contemplated variation is described in the following detailed description for the sake of brevity.

[0034] Examples of provided reinforced textile wheel well liners are found throughout the detailed description below. Related components in an example may be the same, similar, or different in a different example. For the sake of brevity, relevant components will not be explained too much in each example. However, the us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com