A molding process for steel cylinders for chemical industry

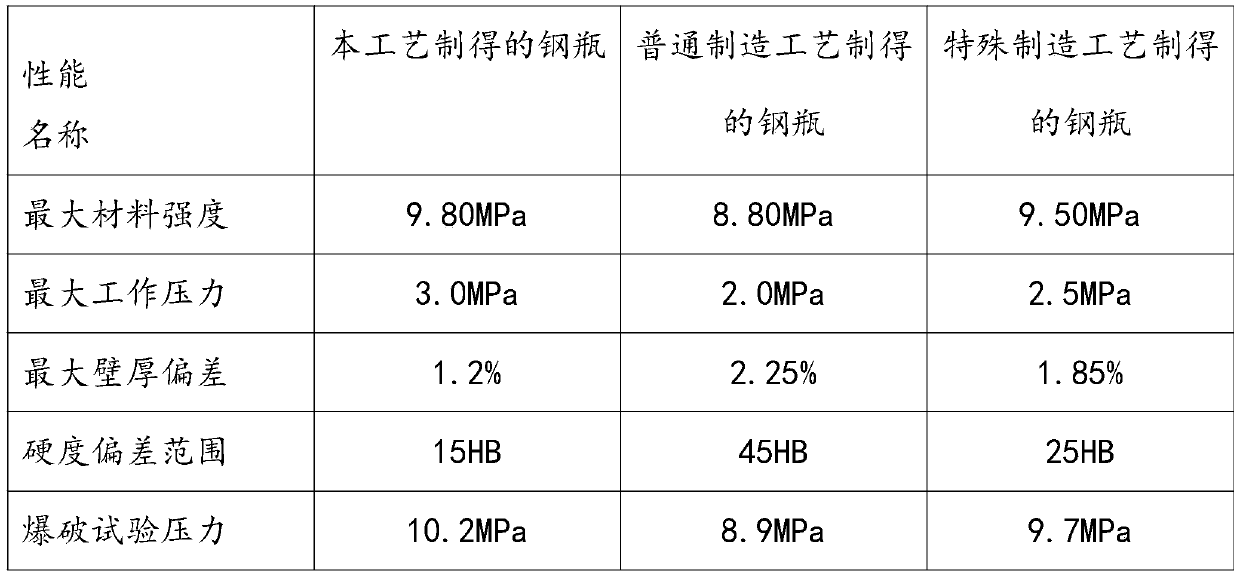

A molding process and steel cylinder technology, which is applied in applications, household appliances, and other household appliances, can solve problems such as low qualified rate of steel cylinders, low production efficiency, and complicated processes, and achieve scientific molding processes, increase production efficiency, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A molding process for chemical steel cylinders, comprising the following steps:

[0017] 1) Steel plate material selection and processing for the production of steel cylinders. The specific steps are: A. Select steel plates that are not folded and perforated in line with the production steel cylinders and set aside; B. Put the steel plates selected in the specific step A into the tempering furnace and heat them to 600°C. After being kept warm for 2 hours, treat it to cool down naturally, obtain the steel plate after the tempering treatment, and set aside; C, the steel plate obtained by the step B tempering process is extruded by a rolling mill, so that the thickness of the steel plate is uniform, and set aside;

[0018] 2) Punching processing of the steel plate: the steel plate with uniform thickness obtained in step 1) is sent into the punching machine tool, and the steel plate is punched out by the punching machine tool to obtain a circular steel plate for making a ste...

Embodiment 2

[0025] A molding process for chemical steel cylinders, comprising the following steps:

[0026] 1) Steel plate material selection and processing for the production of steel cylinders. The specific steps are: A. Select steel plates that are not folded and perforated in line with the production steel cylinders and set aside; B. Put the steel plates selected in the specific step A into the tempering furnace and heat them to 600°C. After being kept warm for 2 hours, treat it to cool down naturally, obtain the steel plate after the tempering treatment, and set aside; C, the steel plate obtained by the step B tempering process is extruded by a rolling mill, so that the thickness of the steel plate is uniform, and set aside;

[0027] 2) Punching processing of the steel plate: the steel plate with uniform thickness obtained in step 1) is sent into the punching machine tool, and the steel plate is punched out by the punching machine tool to obtain a circular steel plate for making a ste...

Embodiment 3

[0034] A molding process for chemical steel cylinders, comprising the following steps:

[0035] 1) Steel plate material selection and processing for the production of steel cylinders. The specific steps are: A. Select steel plates that are not folded and perforated in line with the production steel cylinders and set aside; B. Put the steel plates selected in the specific step A into the tempering furnace and heat them to 600°C. After being kept warm for 2 hours, treat it to cool down naturally, obtain the steel plate after the tempering treatment, and set aside; C, the steel plate obtained by the step B tempering process is extruded by a rolling mill, so that the thickness of the steel plate is uniform, and set aside;

[0036] 2) Punching processing of the steel plate: the steel plate with uniform thickness obtained in step 1) is sent into the punching machine tool, and the steel plate is punched out by the punching machine tool to obtain a circular steel plate for making a ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com