A high-precision thin-walled hollow traveling wave ultrasonic motor

An ultrasonic motor, high-precision technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problems of small hollow parts of motors and low motor rotation accuracy , to achieve the effects of reducing stress concentration, eliminating backlash, and increasing driving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

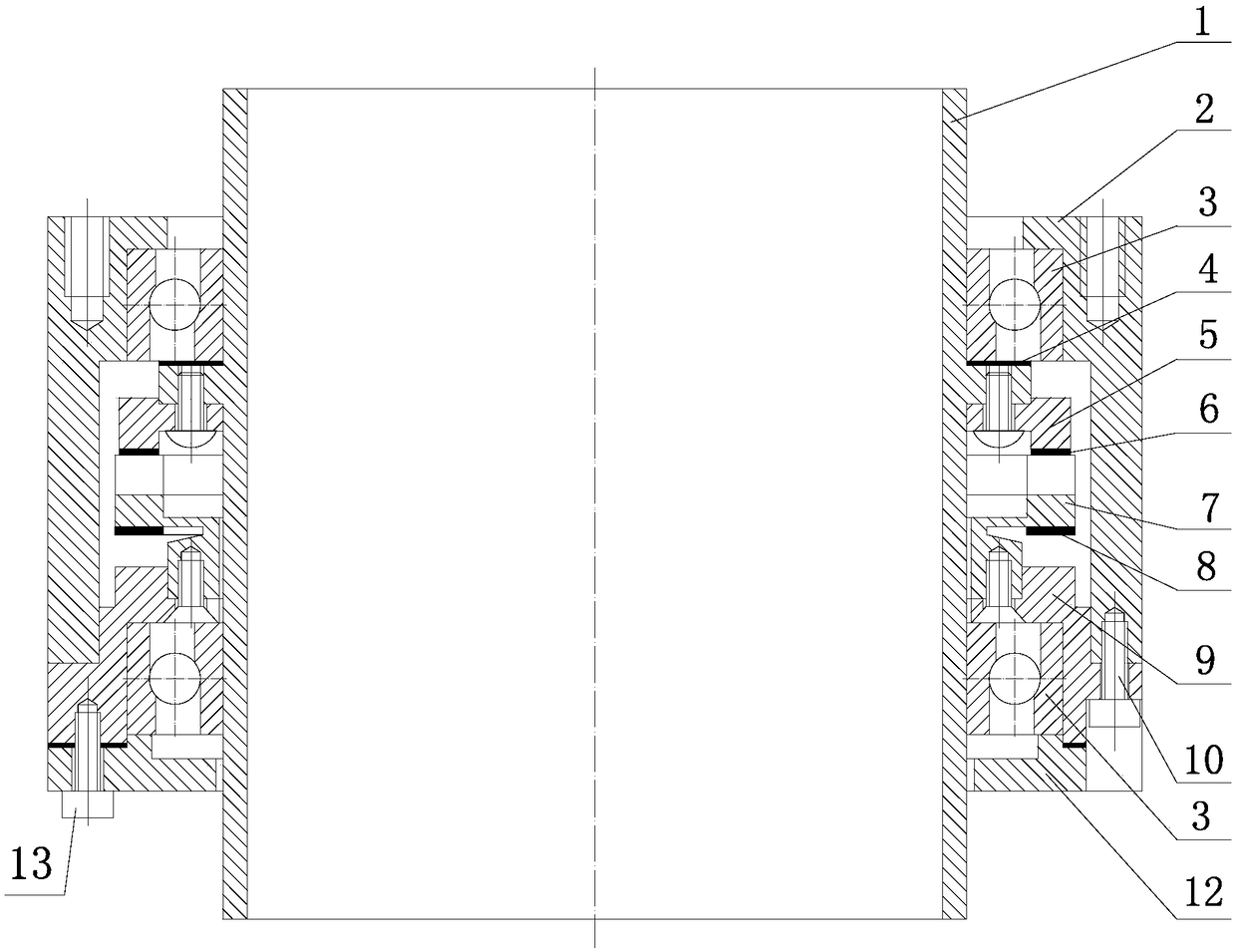

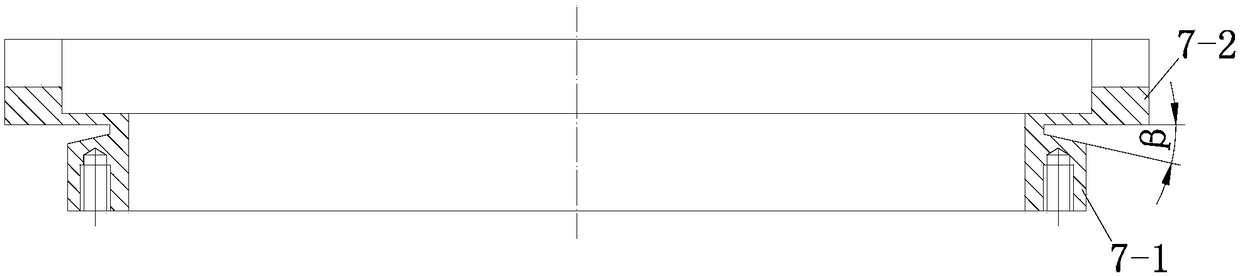

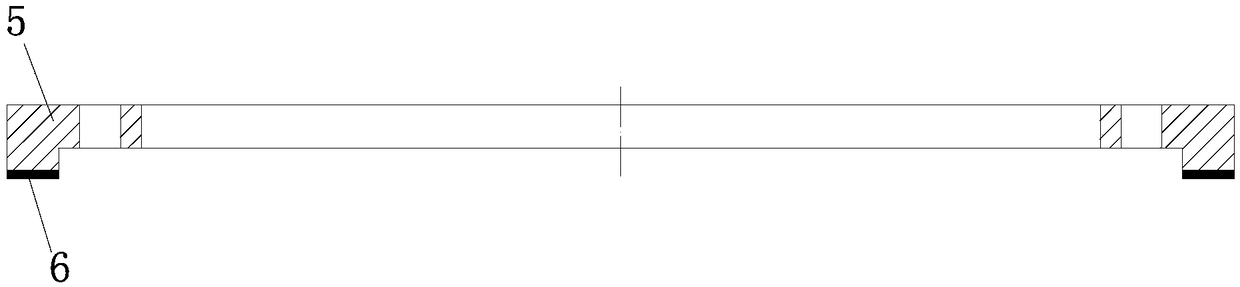

[0016] see Figure 1-Figure 3 Explain that a high-precision thin-walled hollow traveling wave ultrasonic motor includes a hollow shaft 1, a casing 2, a rotor 5, a stator 7 and a base 9; the rotor 5 is mounted on the hollow shaft 1, the casing 2 is mounted on the base 9, and the rotor The friction plate 6 in contact with the stator 7 is arranged on the end surface of the rim of the 5, and the piezoelectric ceramic sheet 8 is laid on the end surface adjacent to the base 9 of the stator 7, and the stator 7 is a folded structure with grooves on its outer surface along the circumferential direction The stator 7 is installed in the positioning installation groove on the base 9 , the hollow shaft 1 is arranged on the shell 2 and the base 9 , and the hollow shaft 1 can rotate relative to the shell 2 and the base 9 .

[0017] The stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com