Method for preparing calcium sulphate whiskers used for absorbing heavy metal ions in waste incineration flue gas

A technology for calcium sulfate whiskers and heavy metal ions, which is applied in separation methods, alkali metal compounds, chemical instruments and methods, etc., can solve the problem of complex preparation and modification process of non-activated carbon adsorbents, unrealized industrial application, and unsatisfactory adsorption efficiency and other problems to achieve the effect of shortening the reaction cycle, short preparation cycle and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

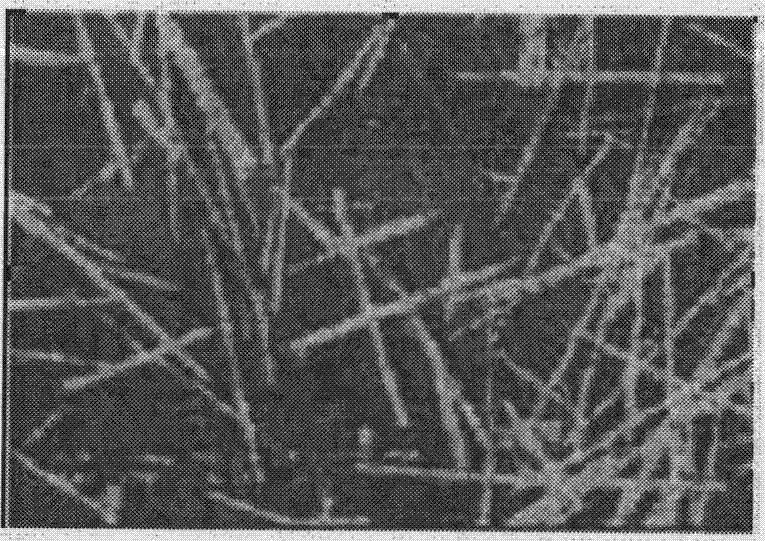

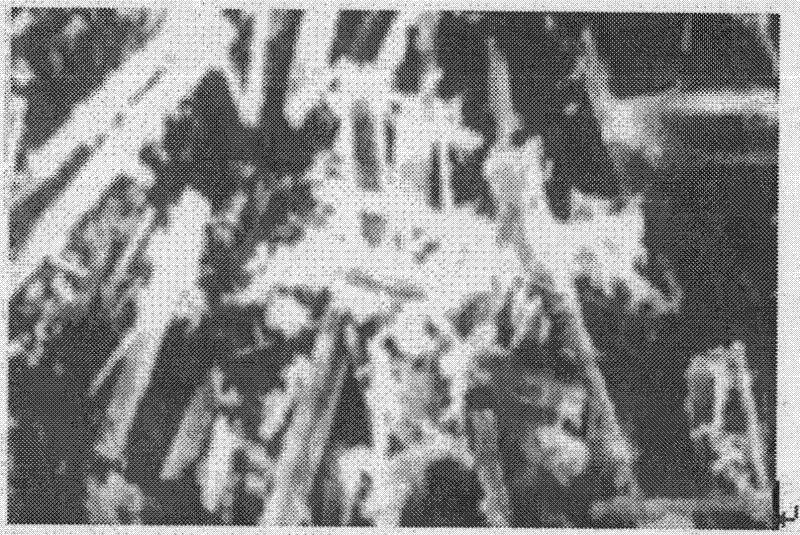

[0017] Weigh 30g of industrial desulfurized gypsum with an average particle size of 50μm, add it to 1L of water and dissolve it fully to form a slurry, add the slurry to the microwave reactor, and then add 0.02molMgCl 2 As a whisker morphology regulator, drop sodium hydroxide solution to adjust the pH value of the slurry to 8; start the stirring device, control the stirring rate to 200rpm, and raise the temperature in the microwave reactor to 130 under normal pressure. ℃, and continue to react at this temperature for 1 h. After the reaction is completed, cool and filter to obtain the crude product of calcium sulfate whiskers (unmodified calcium sulfate whiskers). Then the calcium sulfate whisker crude product that makes is soaked in the NaOH solution of 0.1mol / L in 250ml concentration for 24h, after soaking finishes, take out and dry naturally, put into the muffle furnace then, under the condition of cutting off oxygen, put the horse Furnace is heated up to 700 DEG C, and acti...

Embodiment 2

[0021] Weigh 40g of industrial desulfurized gypsum with an average particle size of 40μm, add it to 1L of water and dissolve it fully to form a slurry, add the slurry to the microwave reactor, and then add 0.03molK 2 SO 4 As a whisker morphology regulator, drop sodium hydroxide solution to adjust the pH value of the slurry to 9; start the stirring device, control the stirring rate to 300rpm, and raise the temperature in the microwave reactor to 130 under normal pressure. ℃, and continue to react at this temperature for 1.5h. After the reaction is completed, cool and filter to obtain the crude product of calcium sulfate whiskers. Then the calcium sulfate whisker crude product that makes is soaked in the NaOH solution of 0.2mol / L in 200ml concentration for 48h, after soaking finishes, take out and dry naturally, put into the muffle furnace then, under the condition of cutting off oxygen, put the horse Furnace is heated up to 800°C and activated at this temperature for 3 hours t...

Embodiment 3

[0025] Weigh 60g of industrial desulfurized gypsum with an average particle size of 30μm, add it into 1L of water and dissolve it fully to form a slurry, add the slurry into the microwave reactor, and then add an appropriate amount of 0.05molK 2 SO 4 As a whisker morphology regulator, drop sodium hydroxide solution to adjust the pH value of the slurry to 10; start the stirring device, control the stirring rate to 400rpm, and raise the temperature in the microwave reactor to 130 under normal pressure. ℃, and continue to react at this temperature for 2 hours. After the reaction is completed, cool and filter to obtain the crude product of calcium sulfate whiskers. Then the calcium sulfate whisker crude product that makes is soaked in 200ml concentration and is the NaOH solution of 0.3mol / L 72h, take out after soaking and dry naturally, put into the muffle furnace then, under the condition of cutting off oxygen, put the horse Furnace is heated up to 900°C and activated at this te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com