Positioning device and metal plate automatic production line

An automatic production line and positioning device technology, applied in positioning devices, feeding devices, storage devices, etc., can solve the problems of gear and rack wear of transmission parts, large deviation of discharging position, and scrapped workpieces, so as to ensure stamping quality, The effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

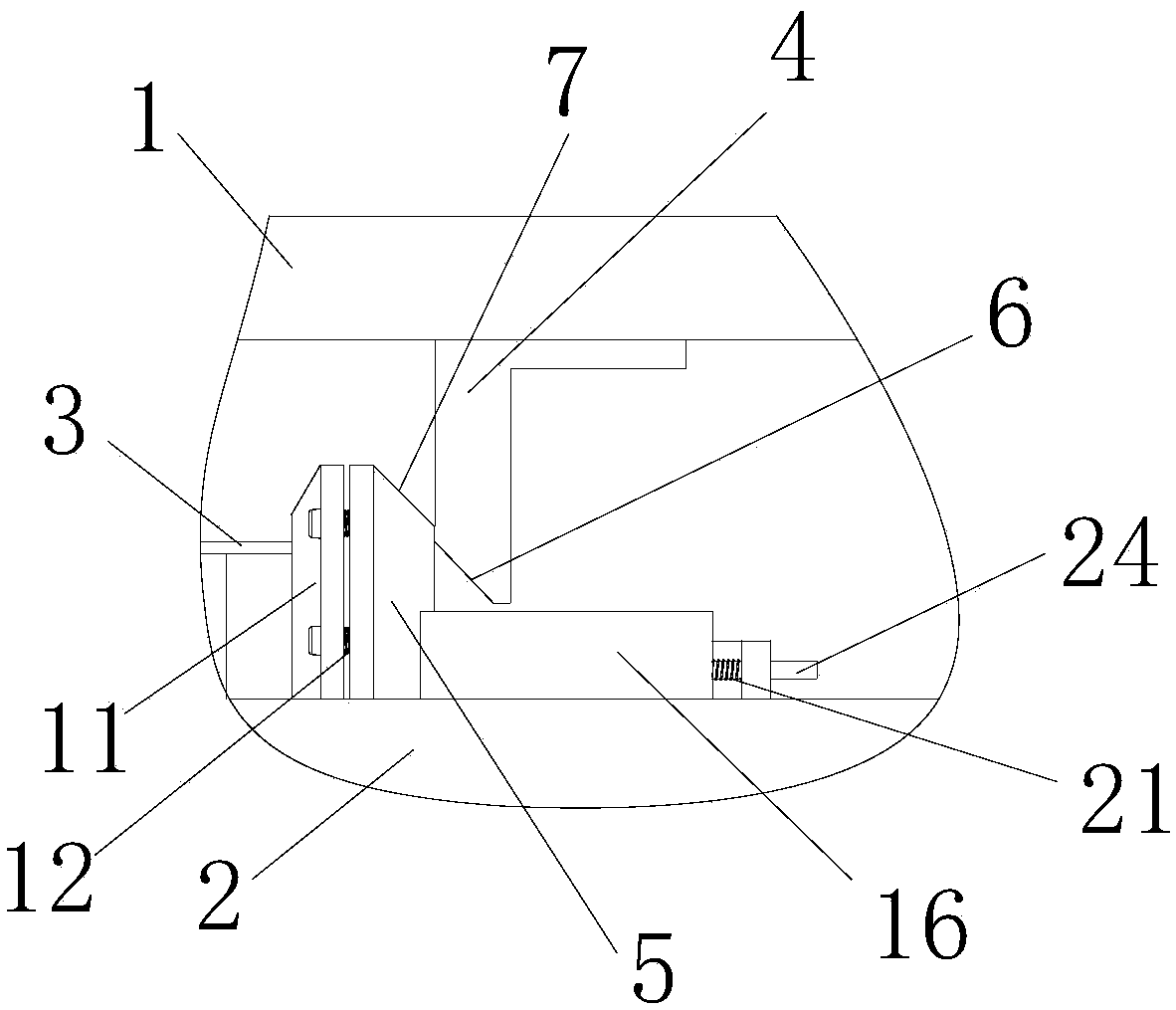

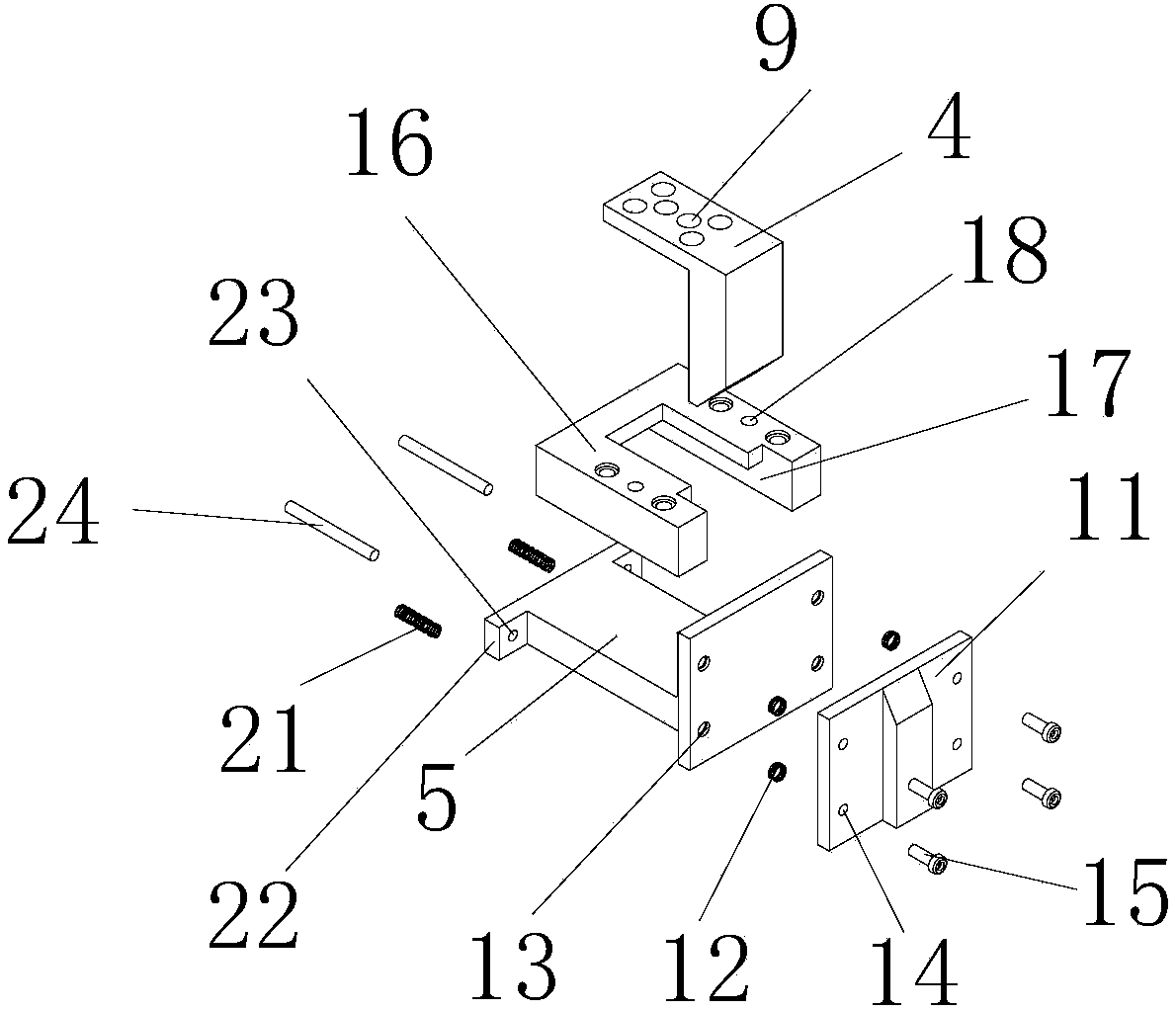

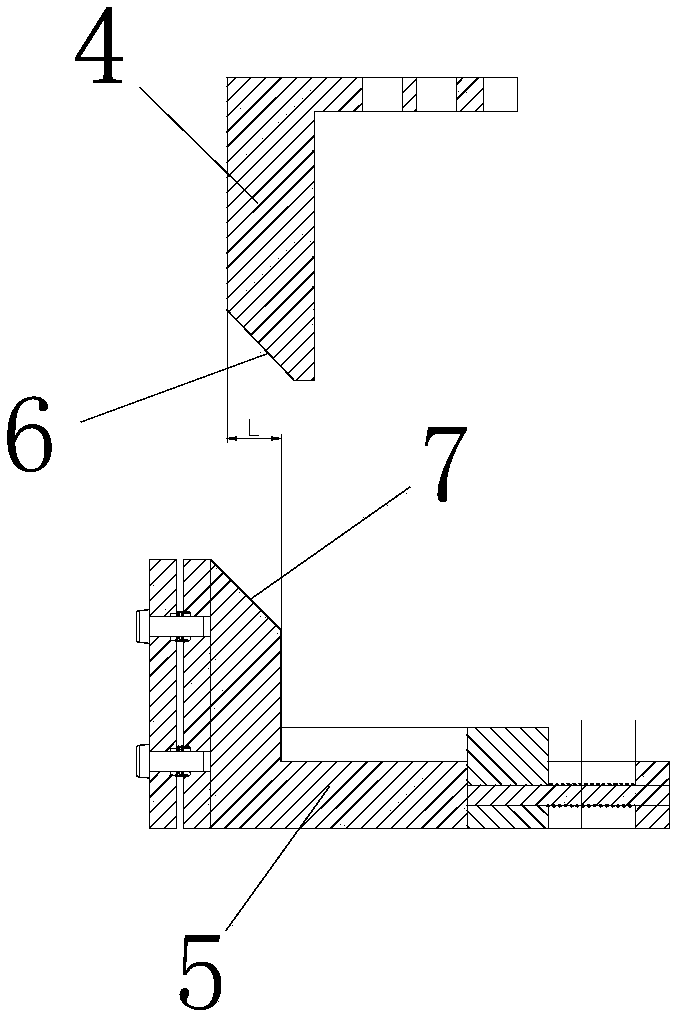

[0050] like figure 1 and figure 2 As shown, a positioning device is used on the mold of the production line. The mold of the production line includes: an upper mold 1 and a lower mold 2, and the upper mold 1 and the lower mold 2 work together to complete the stamping work of the workpiece 3 placed on the lower mold 2 , the positioning device includes: a drive block 4 and a slider 5. The drive block 4 is fixedly connected to the upper die 1, and the slide block 5 is movably connected to the lower die 2. The driving block 4 moves under the drive of the upper die 1, and drives the slider 5 to slide on the lower die 2, and the slider 5 pushes the workpiece 3 to move on the lower die 2 to adjust the position of the workpiece 3.

[0051] Wherein the driving effect of the driving block 4 on the slider 5 can be specifically as follows figure 1 As shown in , the driving block 4 has a driving slope 6, and the slider 5 has a receiving slope 7 corresponding to the driving slope 6.

...

Embodiment 2

[0071] An automatic sheet metal production line is provided with a mold on the automatic sheet metal production line, and the positioning device described in the first embodiment is provided on the mold.

[0072] Preferably, as Figure 7 As shown, a positioning block 25 is also included. As mentioned above, the mold includes an upper mold (not shown in the figure) and a lower mold 2 . The lower mold 2 has a rectangular sheet material holding area 26. In the work, the workpiece is placed in the sheet metal holding area. The workpiece mentioned here can be a sheet metal wool, and the upper mold and the lower mold 2 work together to carry out the sheet metal wool. Stamping shear work.

[0073] The two adjacent sides of the sheet material holding area are fixed sides 27 , and the other two sides are adjustment sides 28 . The number of positioning blocks 25 is at least two, and they are respectively arranged along the two fixed sides 27 , that is to say, at least one positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com