Constant-dance crisped crepe fabric and production process thereof

A production process and fabric technology, which can be used in textiles, fabrics, textiles and papermaking, etc., and can solve the problems of easy yellowing and fading, and expensive silk crepe.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

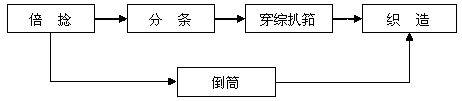

[0034] 1. Warp process

[0035] a. Winding: Use a winding machine, set the winding weight to 0.56kg, the winding time to 280 minutes, and the curling tension to 17g for winding;

[0036] b. Two-for-one twisting: use a two-for-one twisting machine, set the spindle speed to 12000r / min, increase the expansion force beads to 0.7*3 grains, and perform two-for-one twisting with a wrap angle of 180°;

[0037] c. Set the setting temperature at 85 degrees Celsius, and run in 60 minutes;

[0038] d. Sectional warping: set the speed of the large drum at 280m / min, the inverted shaft at 50m / min, and equip with No. 3 tension cap, control the warping tension at 6g, and the inverted shaft at 0.8kg, according to 716 grains* 13 for warping;

[0039] e. Heald threading: 6 pieces of healds are used, and the healds are threaded in a straight-through method;

[0040] 2. Weft process

[0041] a. Winding: Use a winding machine for winding, set the winding weight to 0.56kg, the winding time to 280...

Embodiment 2

[0050] 1. Warp process

[0051] a. Winding: Use a winding machine, set the winding weight to 0.57kg, the winding time to 285 minutes, and the curling tension to 17.5g for winding;

[0052] b. Two-for-one twisting: use a two-for-one twisting machine, set the spindle speed to 12000r / min, increase the expansion force beads to 0.7*3 grains, and perform two-for-one twisting with a wrap angle of 180°;

[0053] c. Set the setting temperature at 85 degrees Celsius, and run in 60 minutes;

[0054] d. Segmented warping: set the speed of the large drum at 280m / min, the inverted shaft at 50m / min, and equip with No. 3 tension cap, control the warping tension at 6.5g, and the inverted shaft tension at 0.85kg, according to 716 grains *13 for warping;

[0055] e. Heald threading: 6 pieces of healds are used, and the healds are threaded in a straight-through method;

[0056] 2. Weft process

[0057] a. Winding: Use a winding machine for winding, set the winding weight to 0.57kg, the windin...

Embodiment 3

[0064] 1. Silk treatment

[0065] a. Winding: Use a winding machine, set the winding weight to 0.57kg, the winding time to 285 minutes, and the curling tension to 18g for winding;

[0066] b. Two-for-one twisting: use a two-for-one twisting machine, set the spindle speed to 12000r / min, increase the expansion force beads to 0.7*3 grains, and perform two-for-one twisting with a wrap angle of 180°;

[0067] c. Set the setting temperature at 85 degrees Celsius, and run in 60 minutes;

[0068] d. Segmented warping: set the speed of the large drum at 280m / min, the inverted shaft at 50m / min, and equip with No. 3 tension cap, control the warping tension at 7g, and the inverted shaft tension at 0.9kg, according to 716 grains* 13 for warping;

[0069] e. Heald threading: 6 pieces of healds are used, and the healds are threaded in a straight-through method;

[0070] 2. Weft process

[0071] a. Winding: Use winding wire for winding, set the winding weight to 0.57kg, the winding time to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Twist | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com