Efficient dip-coating process effect paint and preparation method thereof

A process and high-efficiency technology, applied in chemical instruments and methods, coatings, polyester coatings, etc., can solve the problems of increased yield, irregular wrinkles, uneven wrinkle effects, etc., and achieve the effect of increasing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

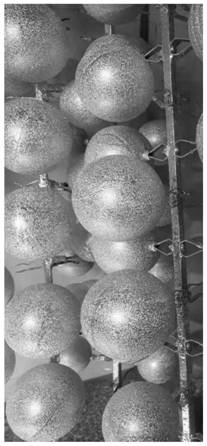

Image

Examples

preparation example Construction

[0039] The second aspect of the present invention provides a method for preparing an efficient dip coating process effect paint, which at least includes the following preparation steps: adding and dispersing the modified alkyd resin and tung oil in a reaction vessel for 5-30 minutes, and then adding a solvent for removing The remaining raw materials outside are dispersed for 5-30 minutes, then add solvent to disperse for 3-20 minutes, and finally filter with a 1u filter bag to obtain a high-efficiency dip coating process effect paint.

[0040] In a preferred embodiment, the rotational speed during dispersion is 200-500 r / min.

[0041] The efficient dip coating process effect paint of the present invention can be used on various substrates, such as plastic substrates and metal substrates, and is especially suitable for plastic substrates (such as PE plastic substrates, PP plastic substrates, ABS plastic substrates) material), especially suitable for ABS plastic substrates, and ...

Embodiment 1

[0047] An efficient dip coating process effect paint, the raw materials of the effect paint include, by weight percentage, modified alkyd resin 62%, tung oil 8.5%, rosin resin 6.3%, drier 3%, leveling agent 1.2% %, the solvent is supplemented to 100%;

[0048] Described modified alkyd resin is rosin phenolic modified linseed oil alkyd resin, purchased from Shenzhen Degao Bisheng Chemical Co., Ltd., model is 3729-X-70; described tung oil is purchased from Guangzhou Zhuochang Chemical Co., Ltd. Tung oil; the drier is purchased from Shanghai Changfeng Auxiliary, the model is ZHV-68; the rosin resin is a rosin-modified phenolic resin, purchased from Deqing Wanli Resin Factory, the model is 210#; the leveling agent It is BYK-333 leveling agent, purchased from Guangzhou Yangfan Chemical Co., Ltd.; the solvent is the combination of butanone and ethyl acetate, and its weight ratio is 9:10;

[0049] The preparation method of the high-efficiency dip coating process effect paint is as f...

Embodiment 2

[0052] An efficient dip coating process effect paint, the raw materials of the effect paint include, by weight percentage, 60% of modified alkyd resin, 10% of tung oil, 5.5% of rosin resin, 2% of drier, and 1% of leveling agent. %, the solvent is supplemented to 100%;

[0053] Described modified alkyd resin is rosin phenolic modified linseed oil alkyd resin, purchased from Shenzhen Degao Bisheng Chemical Co., Ltd., model is 3729-X-70; described tung oil is purchased from Guangzhou Zhuochang Chemical Co., Ltd. Tung oil; the drier is purchased from Shanghai Changfeng Auxiliary, the model is ZHV-68; the rosin resin is a rosin-modified phenolic resin, purchased from Deqing Wanli Resin Factory, the model is 210#; the leveling agent It is BYK-333 leveling agent, purchased from Guangzhou Yangfan Chemical Co., Ltd.; the solvent is the combination of butanone and ethyl acetate, and its weight ratio is 10:11.5;

[0054] The preparation method of the high-efficiency dip coating process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com