Control method and control system for welding melting amount of electrode at spark plug side

A technology of control system and control method, applied in welding monitoring device, welding power source, welding equipment, etc., can solve the problems of not having welding melting amount monitoring function, increasing the quality cost of enterprises, scrapping products in batches, etc., so as to achieve real-time monitoring of products. quality, improve welding quality and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Provided is a spark plug side electrode welding melting amount control method, including welding electrodes, which includes the following steps:

[0034] a. Record the displacement value before welding: when the welding electrode drives the product to contact the side electrode, apply pressure to the product through the welding electrode, so that the pre-welding pressure is generated between the product and the side electrode, and record the displacement value of the product at this time;

[0035] b. Record the displacement value after welding: After the welding electrode completes the welding operation on the product and the side electrode and is still in contact with the side electrode, keep the welding pressure applied by the welding electrode to the product, and record the displacement value of the product at this time;

[0036] c. Data calculation and processing: calculate the difference between the displacement value before welding and the displacement value after ...

Embodiment 2

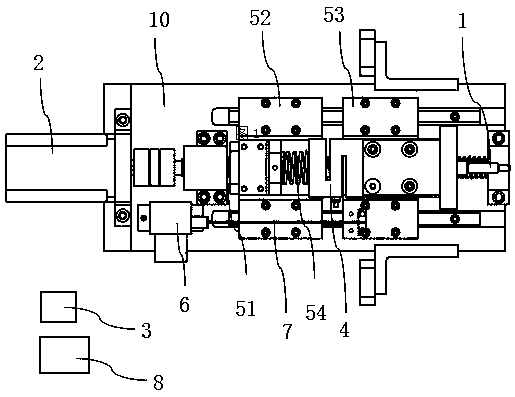

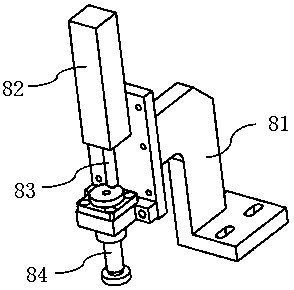

[0043] A system for realizing the above-mentioned method for controlling the welding melting amount of the electrode on the side of the spark plug is provided, including a welding machine 10 and a welding electrode 1. The welding machine 10 is provided with a power element 2, a signal control device 3, a transmission mechanism, and a pressure sensing device 4. One end of the transmission mechanism is connected to the power element 2, and the other end is connected to the welding electrode 1. The power element 2 provides displacement power for the transmission mechanism. The pressure sensing device 4 is installed in the transmission mechanism. The pressure sensing device 4 can measure the welding pressure of the welding electrode 1 , and the welding pressure is fed back to the signal control device 3, and the signal control device 3 is connected to the power element 2 with a signal.

[0044]In order to grasp the actual welding melting amount of the electrode on the side of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com