Patents

Literature

46results about How to "Monitor product quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Execution method of computer integrated manufacturing based on cloud manufacturing and system thereof

InactiveCN103095808ARealize informatizationInexpensive and unlimited expansion of storage spaceTransmissionVirtualizationResource pool

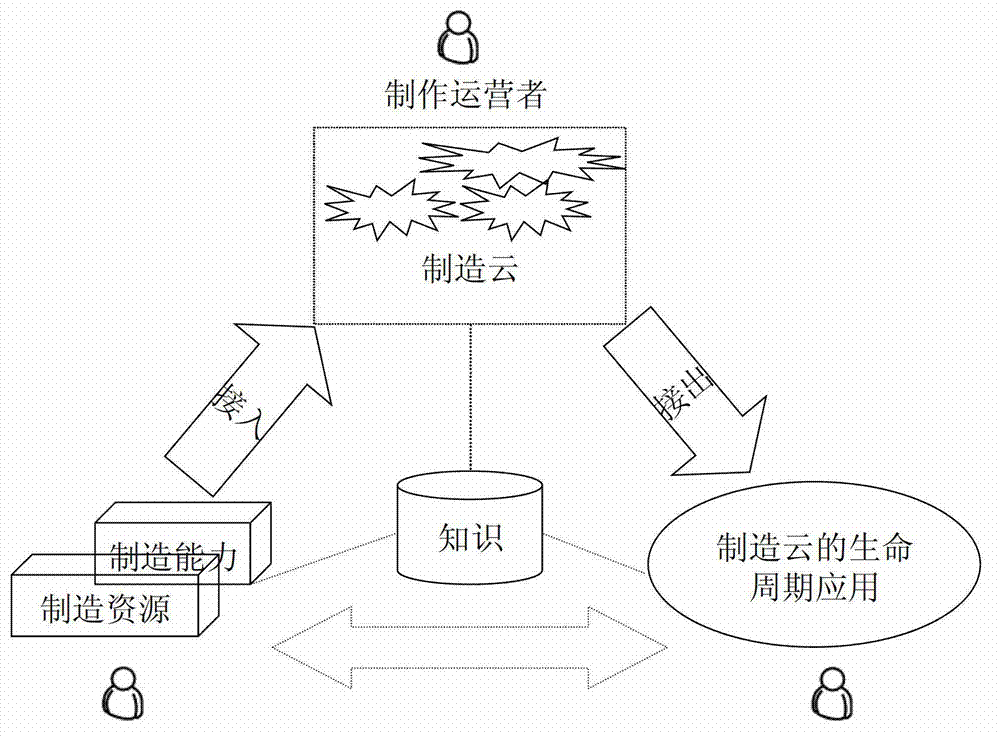

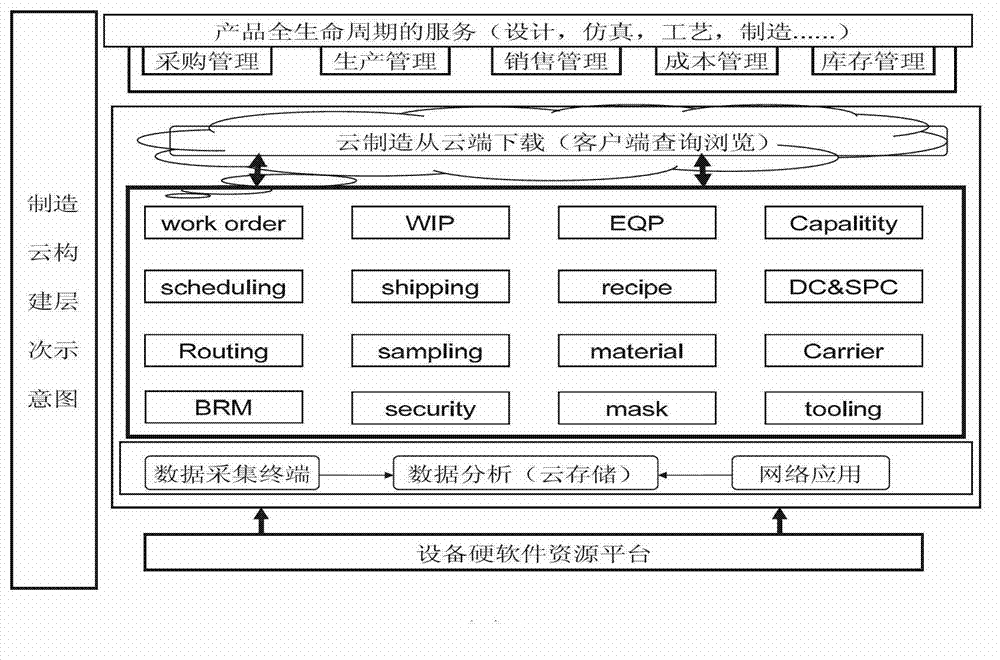

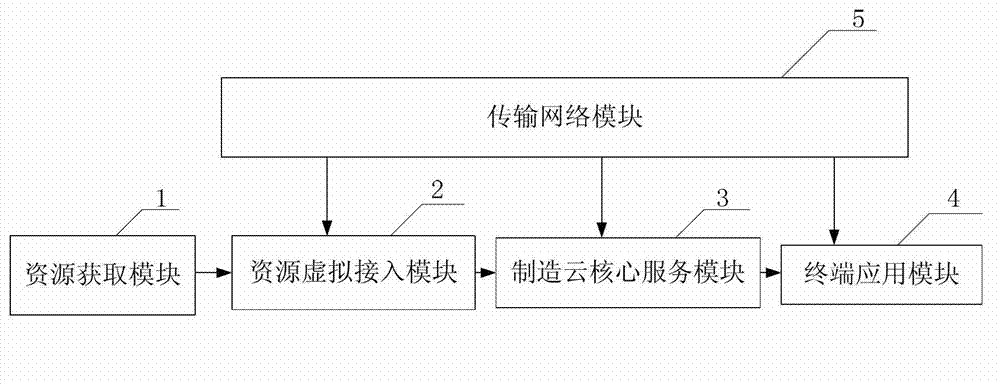

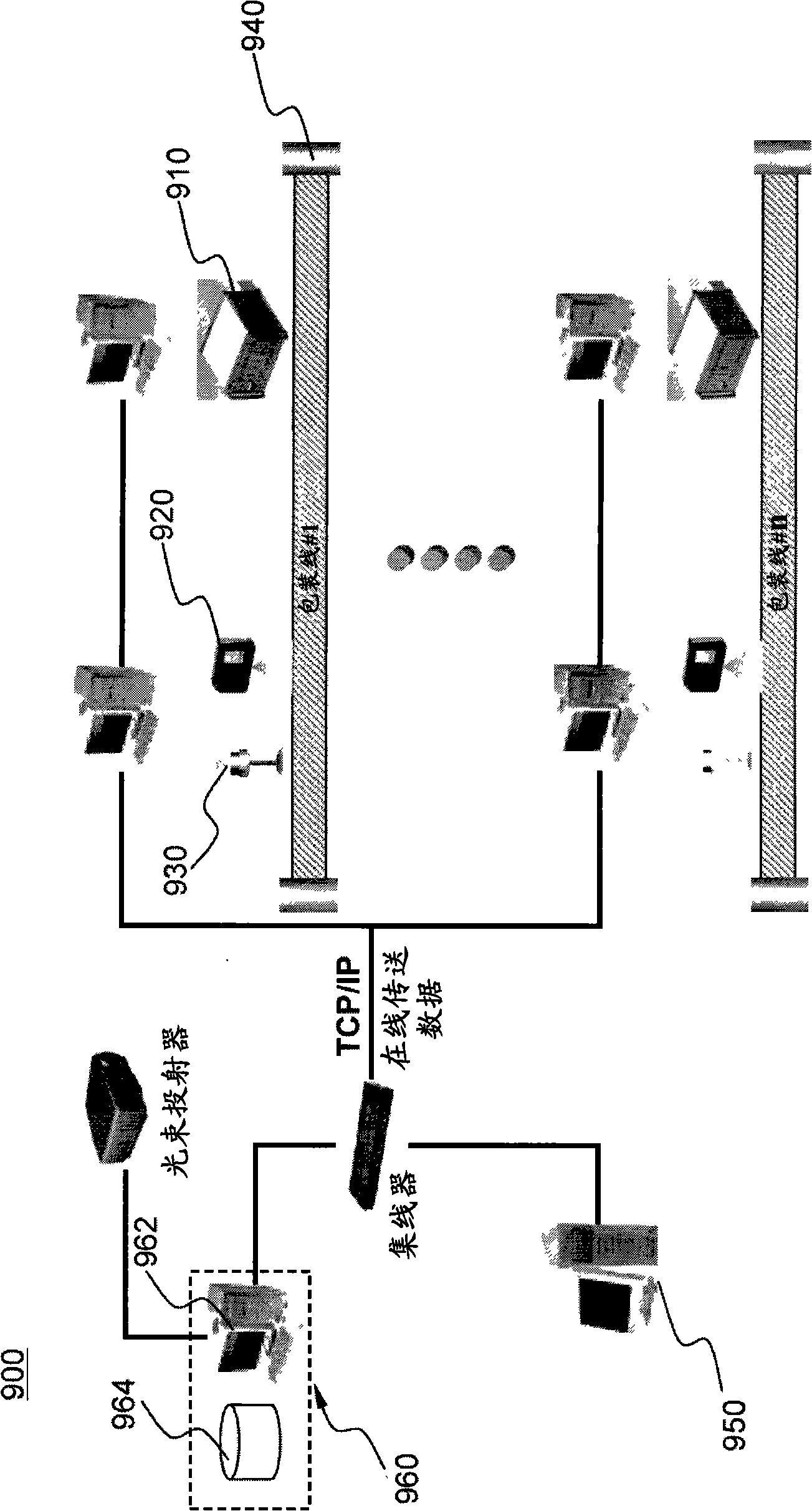

The invention discloses an execution method of computer integrated manufacturing based on cloud manufacturing and a system thereof, and relates to the field of virtual network resource sharing. The execution method of the computer integrated manufacturing based on cloud manufacturing comprises the following steps: S1, obtaining product resource information relating to a whole product life cycle provided by a product manufacturer, classifying or integrating the product resource information according to the contents, and obtaining pending input information, S2, collecting the pending input information together to form a virtual resource pool by means of virtualization technology, S3, creating a cloud platform according to the virtual resource pool in a network operation environment so that a user is capable of applying and managing the product with the help of cloud service provided by the manufacturing cloud platform, S4, obtaining the product resource information after interaction with the cloud platform. The execution method of computer integrated manufacturing based on cloud manufacturing and the system thereof have the advantages that automation level and entire production efficiency of a manufacturing industry are improved and group informatization of factories or manufacturing-type enterprises is realized.

Owner:IRICO FOSHAN FLAT PANEL DISPLAY

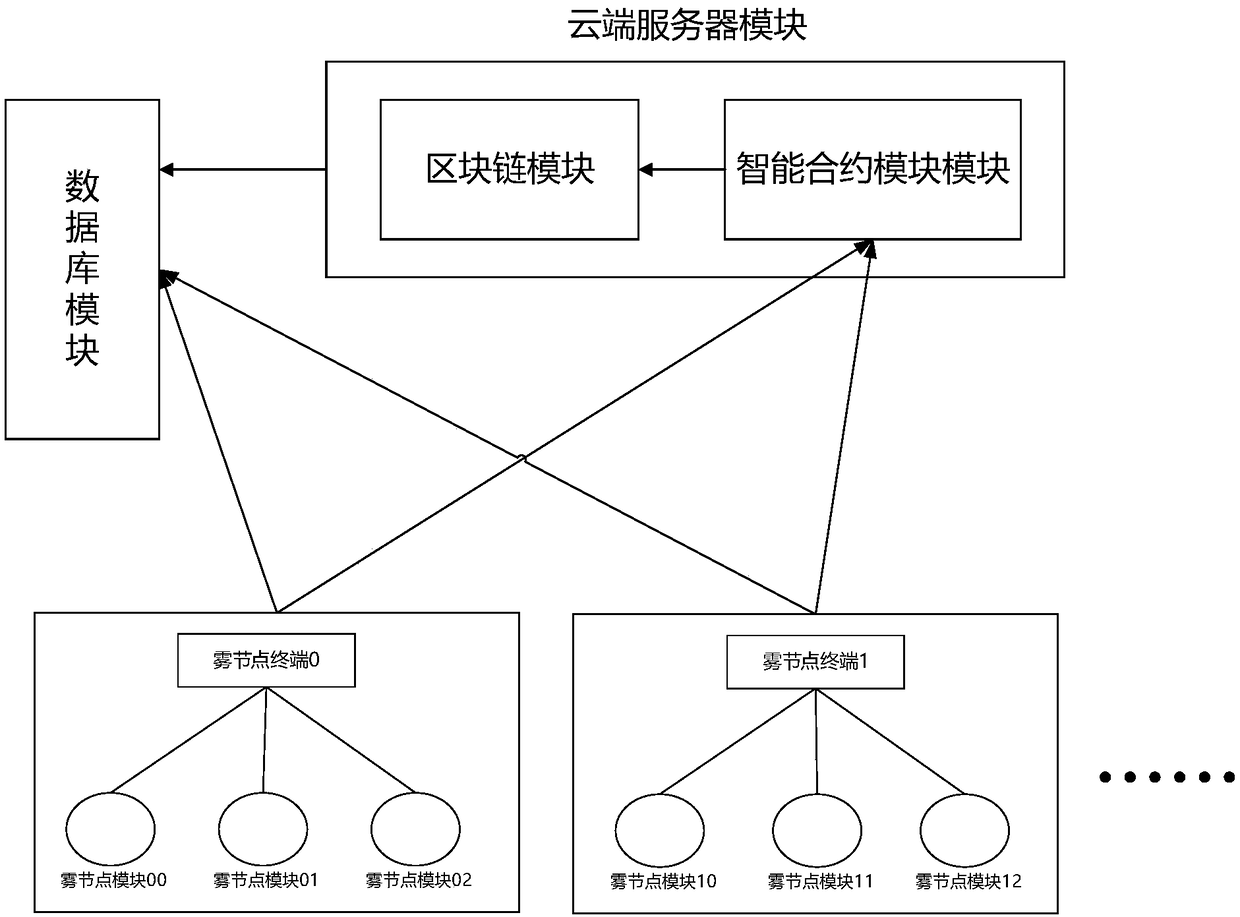

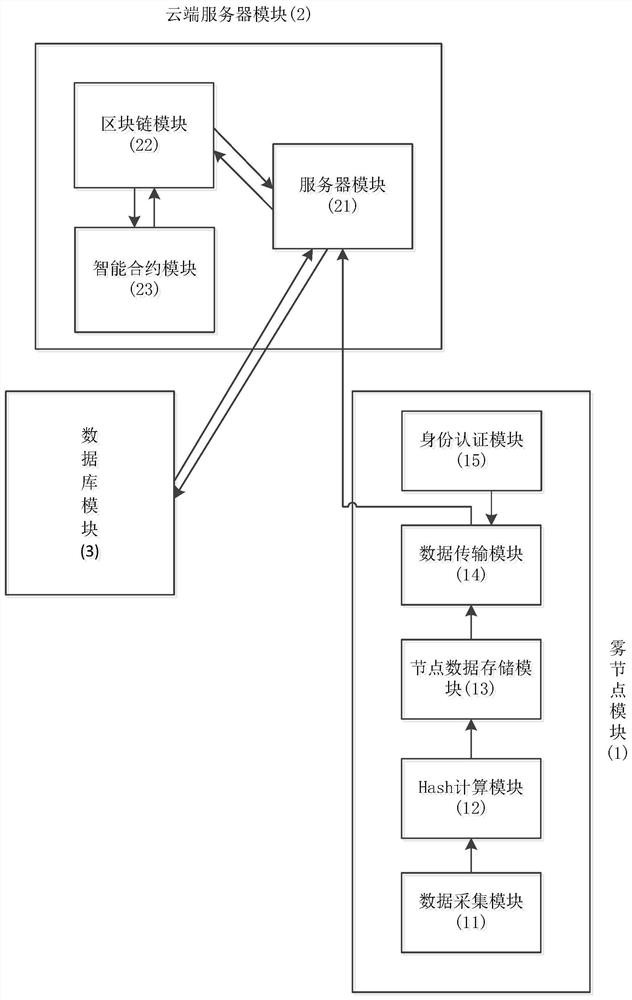

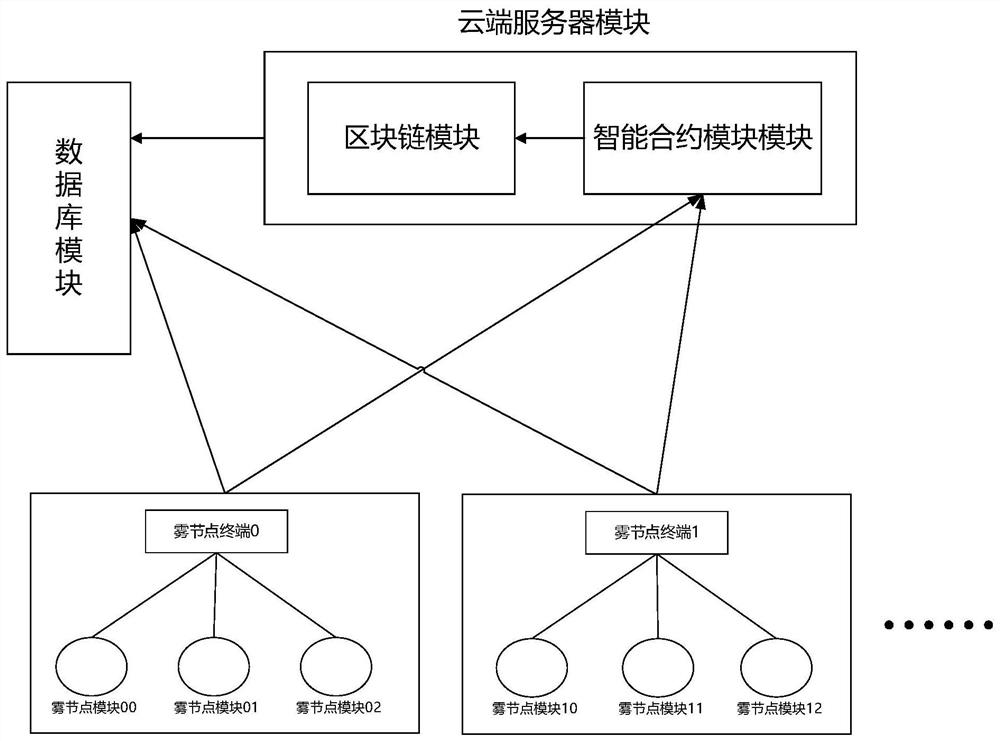

Monitoring method of commodity logistics environment based on intelligent contract and fog calculation

ActiveCN109087005AEasy accessRelieve pressurePayment protocolsResourcesLogistics managementSmart contract

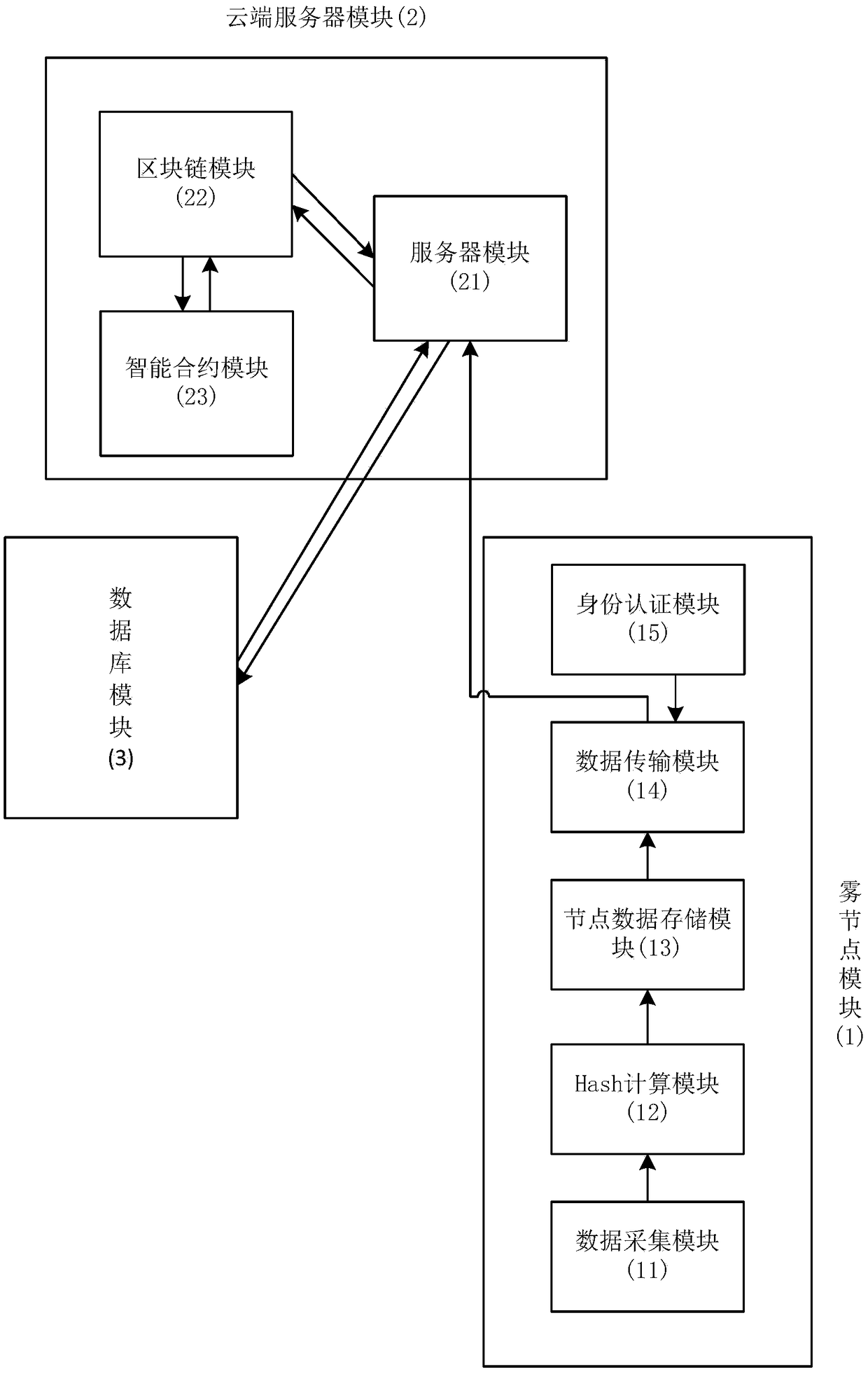

The invention discloses a monitoring method of commodity logistics environment based on intelligent contract and fog calculation, which is characterized in that user identity and authority are identified by fog node module; commodity sales routes are set by coding, a commodity storage environment threshold is set by an intelligent contract, the commodity circulation process is standardized; hash calculation is carried out by collecting commodity status information through that sensor in time, and the calculation result is stored and uploaded into the block chain, and the status information isstored in a local and a database, so as to monitor the commodity circulation status and the product quality; through the anti-counterfeit code link to each commodity, the circulation information and status information of the commodity are inquired. The invention can monitor the circulation chain and the product quality of the whole circulation link of the commodity, notify the whole network of theunqualified product information, and solidify the evidence.

Owner:HEFEI UNIV OF TECH

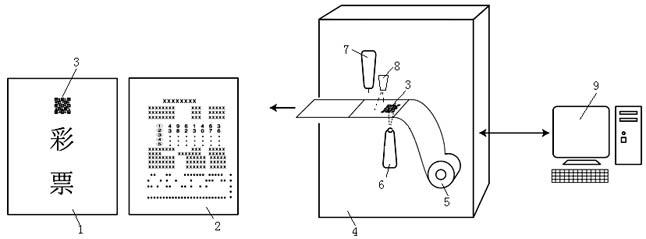

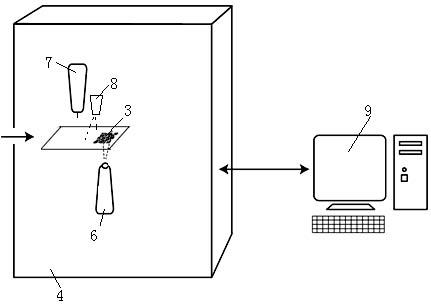

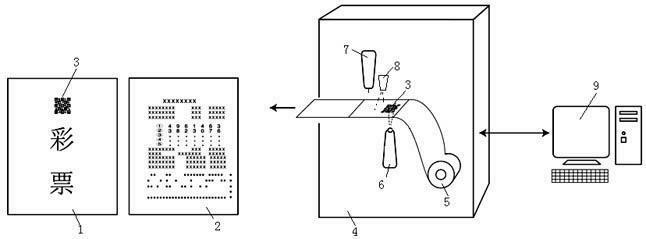

Lottery anti-counterfeiting method

ActiveCN102509378AImprove sales securityImprove ticket management efficiencyPaper-money testing devicesSensing record carriersComputer securityUnique identifier

The invention relates to a lottery anti-counterfeiting method. According to the invention, a group of information carriers, which are provided with a unique identifier and can be read by a terminal device, are additionally printed on the lottery surface during the computer lottery printing production link; and in the lottery marketing process, the information identifier on the lottery surface is read before the lottery number selection information is printed, so the data on the lottery surface can be in one-to-one correspondence with the data in the computer lottery marketing system, and the relevance between the lottery surface information identification and the computer lottery marketing system is realized. Therefore, even with the winning information and real paper, a counterfeiter can not reproduce a uniform winning lottery for cashing, and the real lottery anti-counterfeiting is realized.

Owner:HONGBO CO LTD

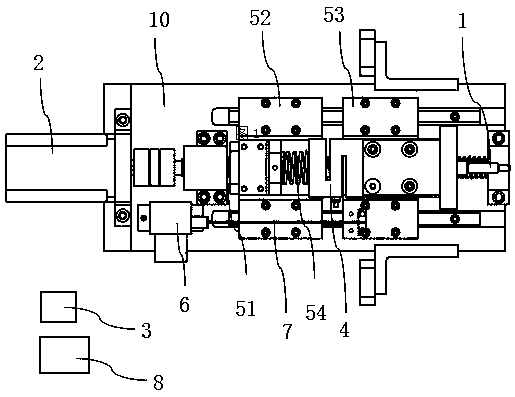

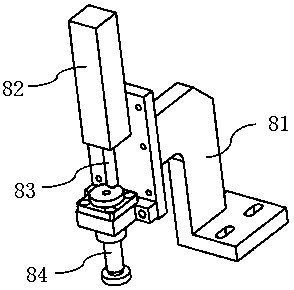

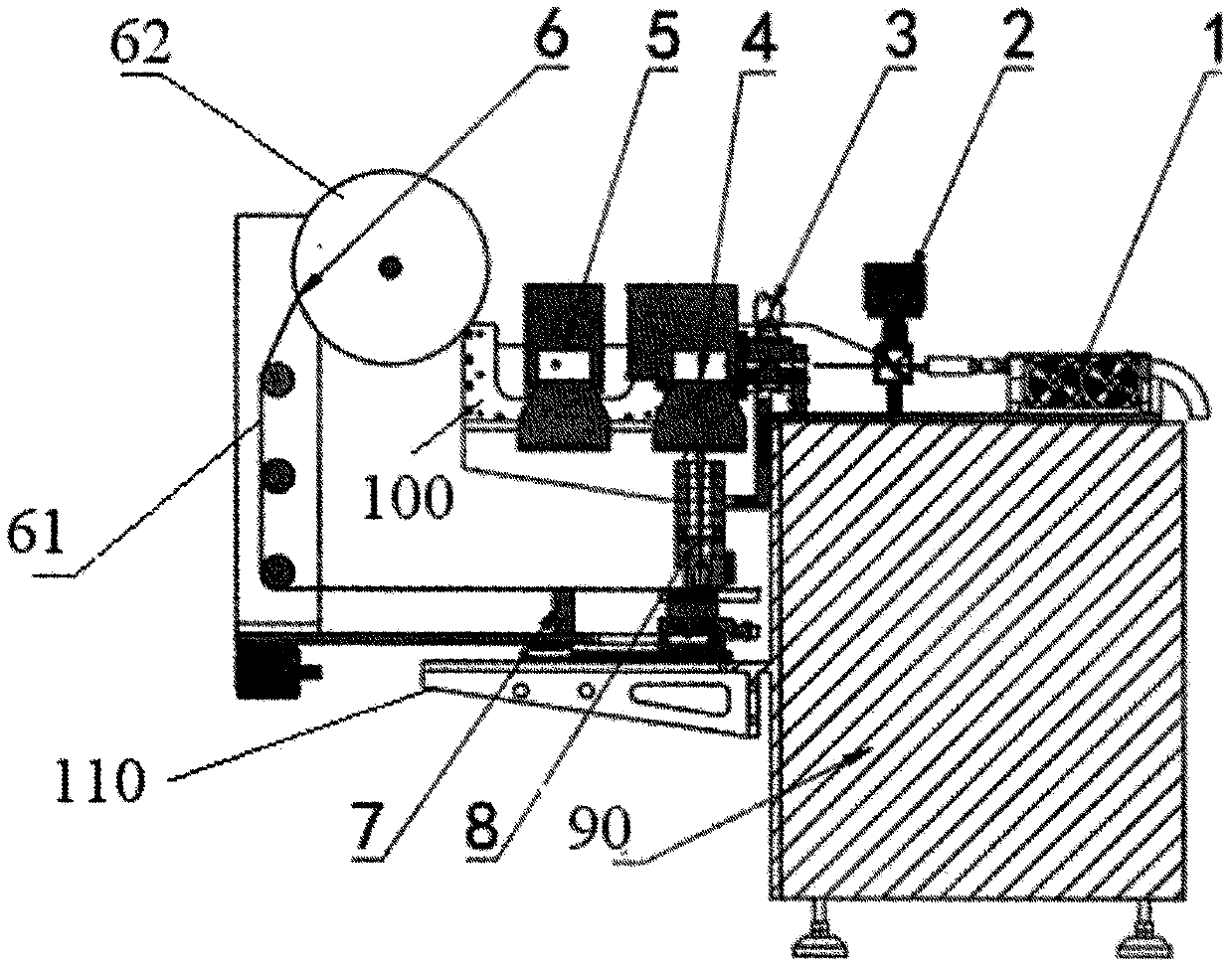

Automatic press-mounting method and equipment for optical transceiver assembling member

ActiveCN102401948AImprove efficiencyIncrease productivityAssembly machinesCoupling light guidesManufacturing technologyTransceiver

The invention discloses an automatic press-mounting method and equipment for an optical transceiver assembling member and belongs to the technical field of manufacturing optical communication devices. The automatic press-mounting method for the optical transceiver assembling member disclosed by the invention comprises the following steps of: placing a metal tail-handle, covering the upper cover of a press-mounting tool, placing a ceramic ferrule, applying pressure to the upper cover of the press-mounting tool to form a tail-handle assembly, taking away the upper cover of the press-mounting tool, screening unqualified products with poor pressure-bearing capability and skimming off products with qualified sizes and products with ultra-poor sizes. The invention further discloses automatic press-mounting equipment for the optical transceiver assembling member. According to the automatic press-mounting equipment for the optical transceiver assembling member disclosed by the invention, the automatic feeding during the press-mounting process and the full-automatic operation during the press-mounting process are solved; whether the force is out of limits and the press-mounting matching size is qualified during the press-mounting process can be judged, and the quality characteristics of the products can be selected automatically; the structure is simple and the operation is simple and convenient; the automatic operation of the complete device is realized, and the reduction of labor force, the increasing of efficiency and the reduction of cost are achieved.

Owner:FINETOP SCI &TECH

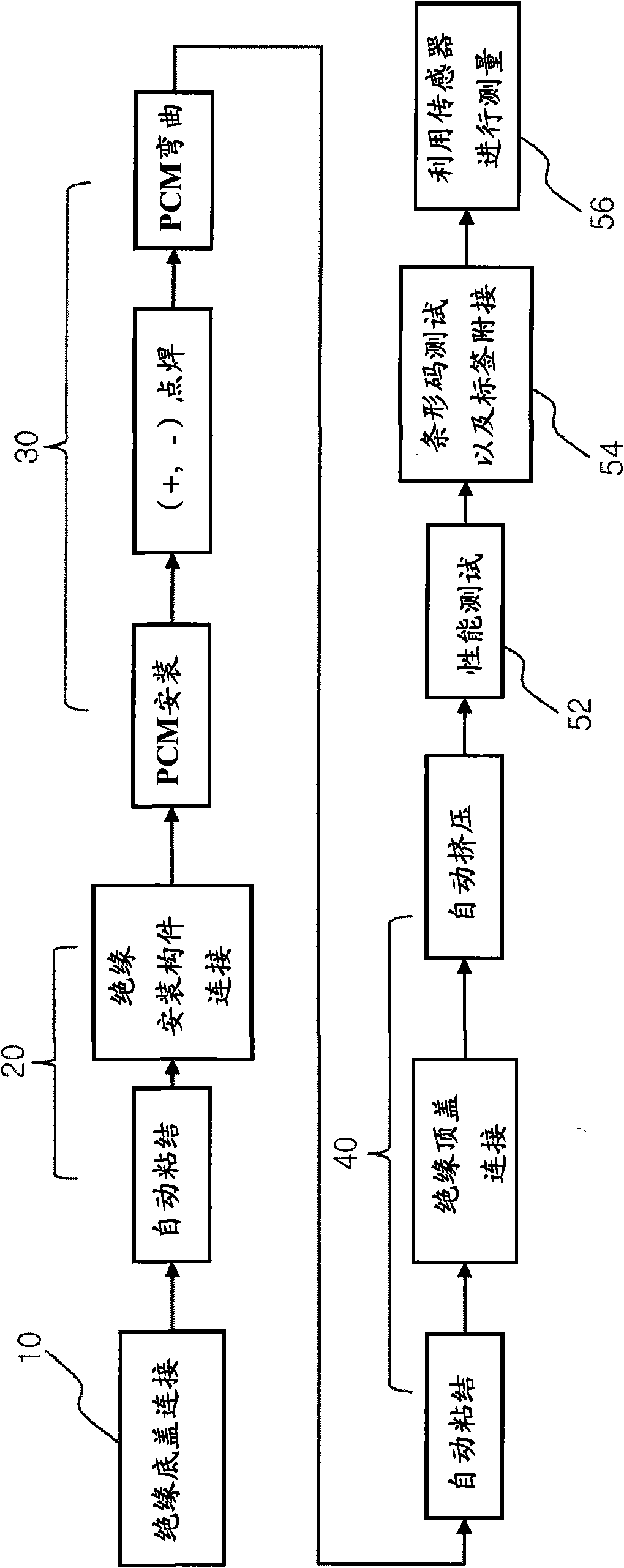

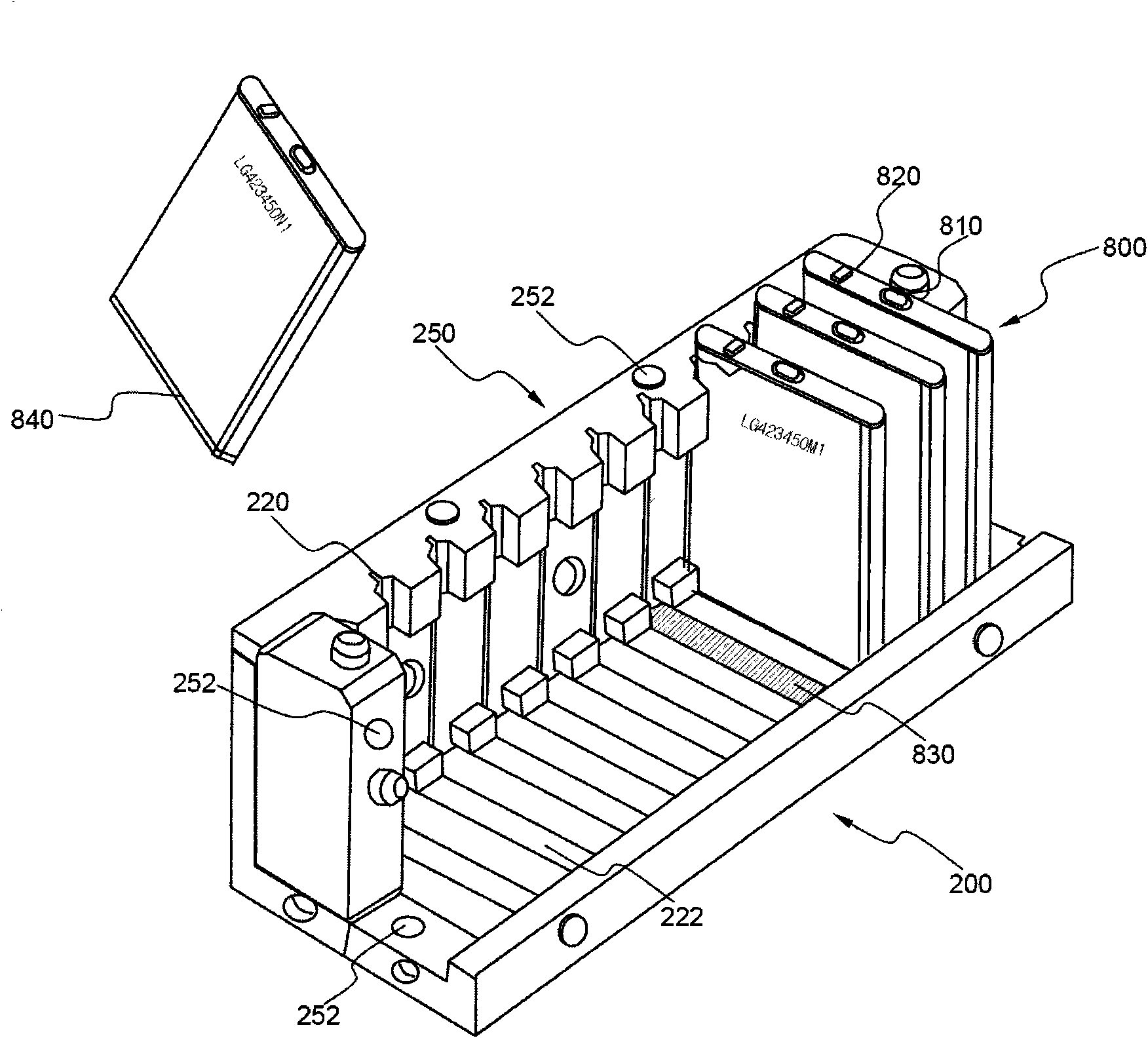

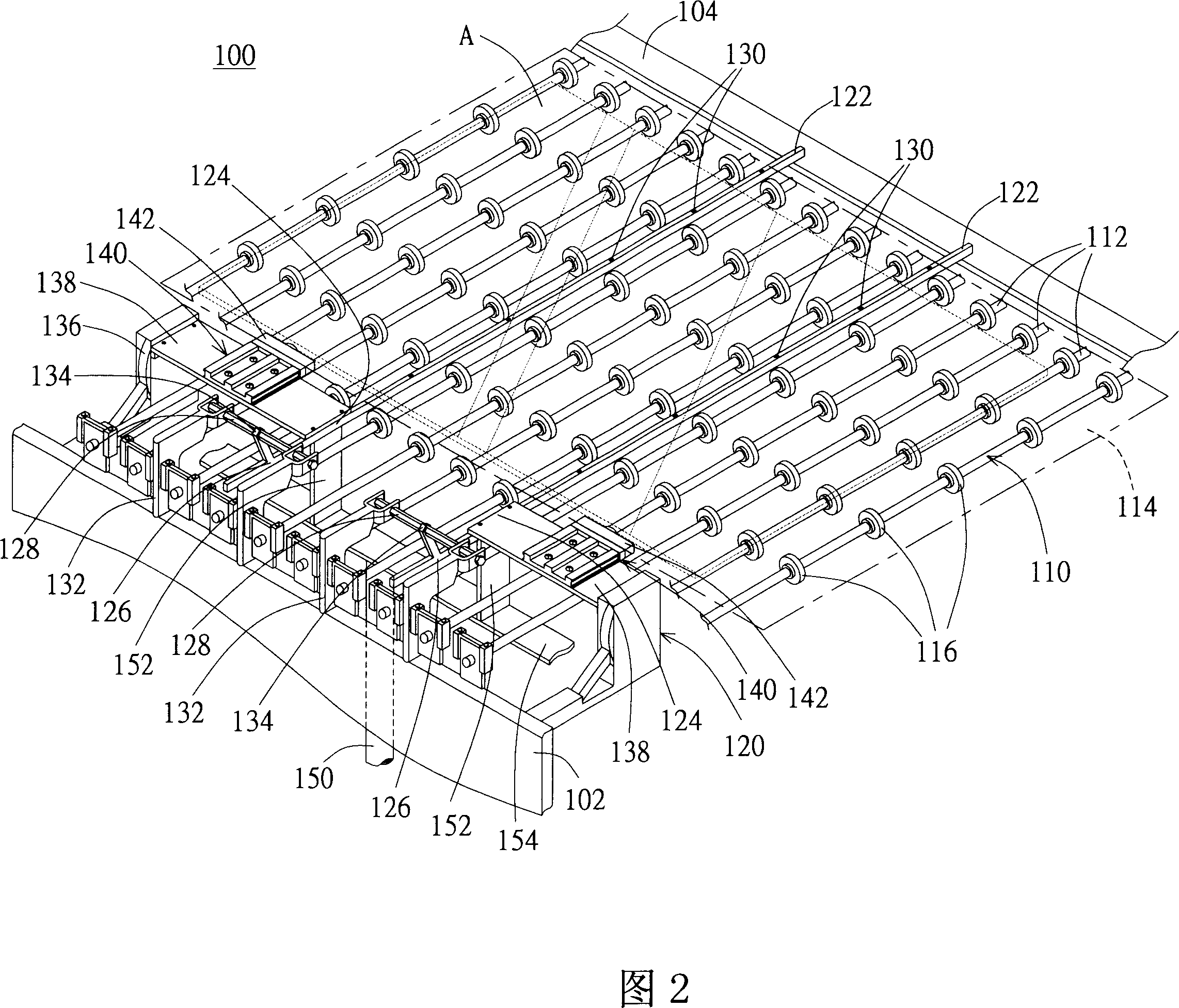

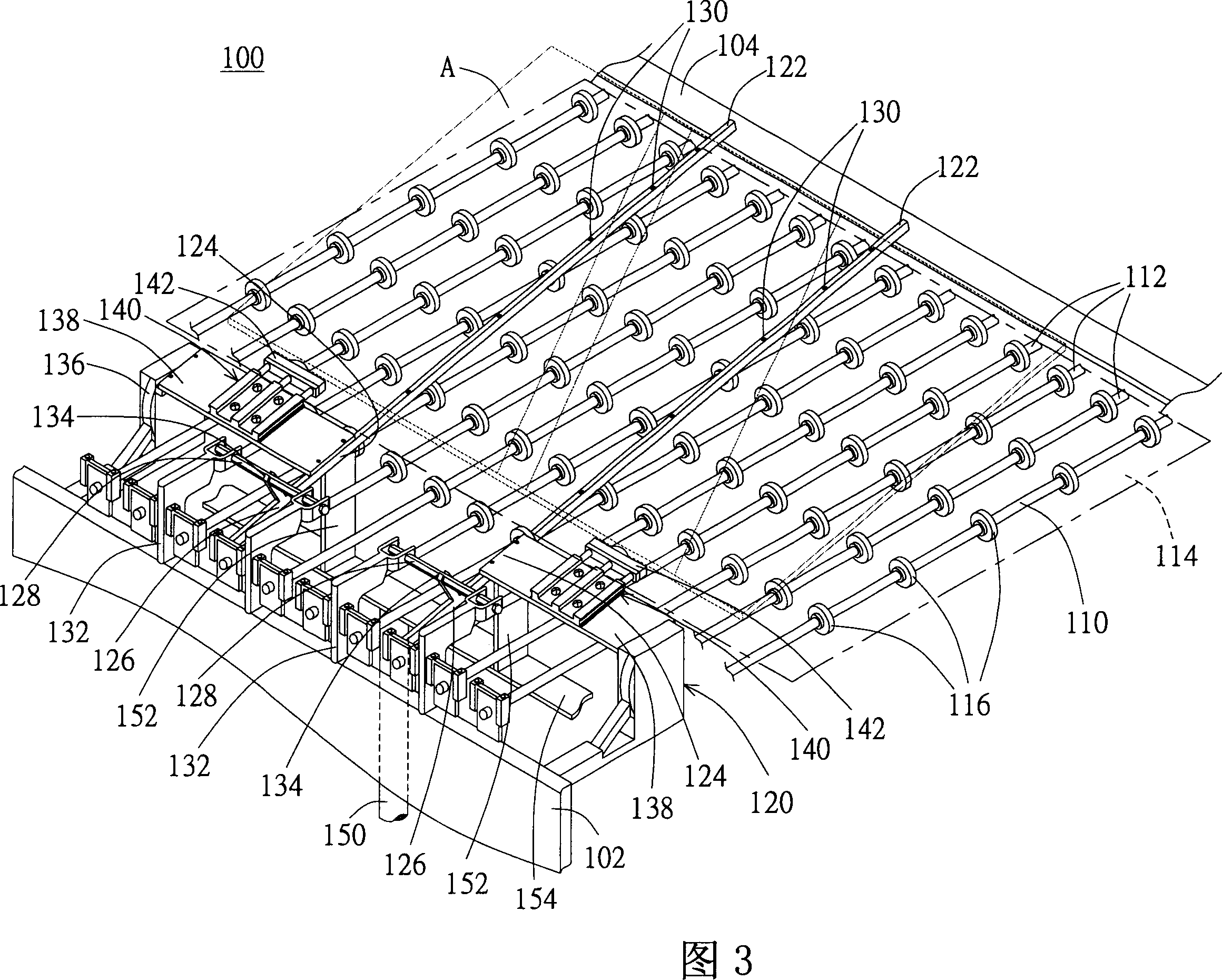

Manufacturing method of battery pack and manufacturing process monitoring system for the same

ActiveCN101662037AReal-time monitoring statusEasy to implementProgramme controlAssembling battery machinesElectricityAdhesive

The present invention discloses a method for manufacturing a batter pack from a plurality of battery cells via a continuous operation, the manufacturing method comprises: (a) putting the battery cellsin a bearing clamp, and mounting insulating covers onto the bottom end of each battery cells; (b) after positioning each of metal clads to one side of the top end of each one corresponding battery cells in the battery cells, combining the metal clads to top ends of each battery cells by welding; (c) mounting additive to bottom end of each insulating mounting components or top end of each batterycells, so as to combine the insulating mounting components to the top end of each battery cells; (d) after positioning each one of protective circuit modules to the top end of one corresponding insulating mounting module of the insulating mounting modules, electrically connecting the protective circuit module to each battery cells by using a preset welding equipment; (e) applying the adhesive to the outer surface of the top end of each protective circuit modules or the inner surface of each insulating top covers, and combining each insulating top covers to each protective circuit modules or each battery cells by this way, that is, the insulating top covers surround each protective circuit modules; (f) taking out the battery pack from the bearing clamp; (g) testing the performance of each battery pack by using a battery pack testing equipment, and transmitting the testing data (A) to a data server; (h) coating the outer surface of each battery packs in a protecting film, testing the barcodes attached to the outer surface of a protecting film, and transmitting the testing data (B) to the data server; and (i) testing the size of each battery cells by using a sensor, and transmittingthe testing data (C) to the data server.

Owner:LG ENERGY SOLUTION LTD

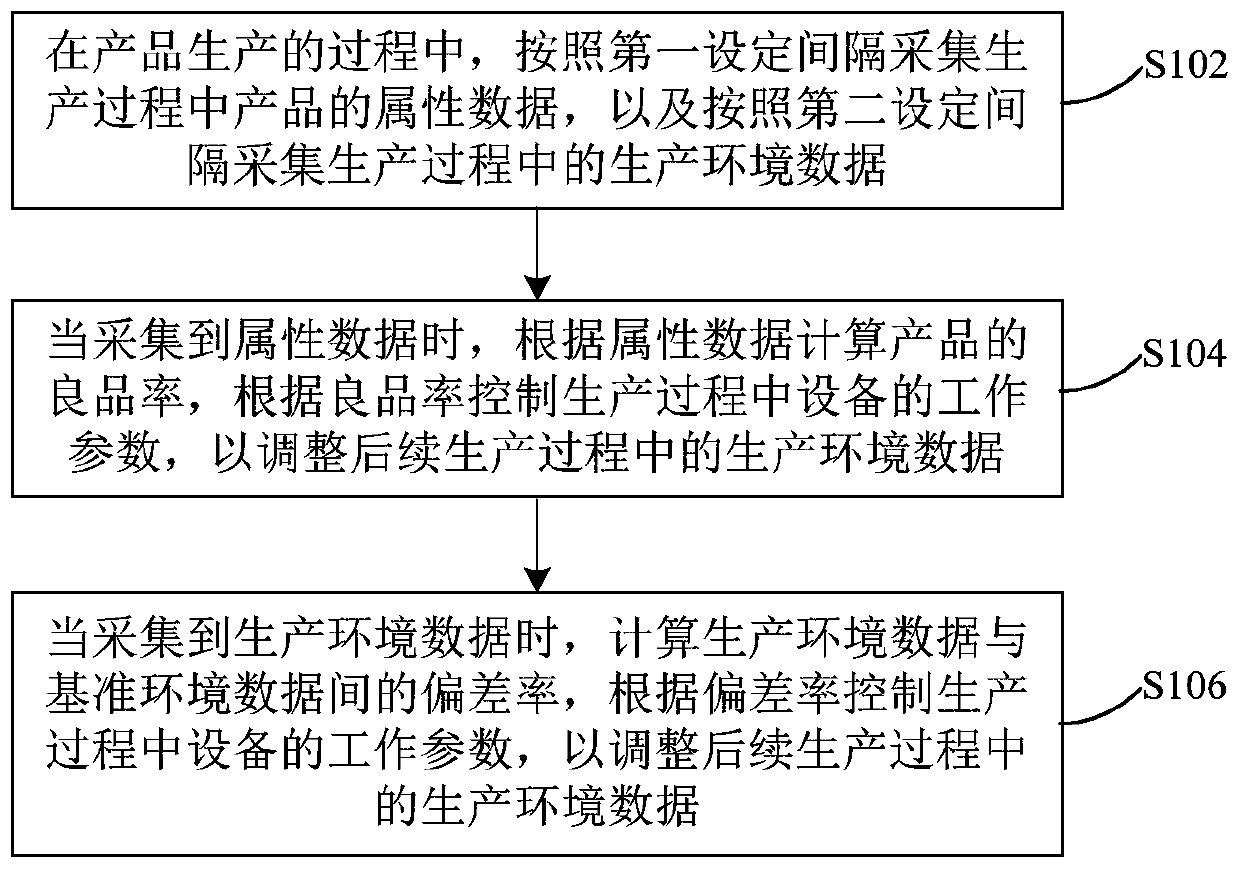

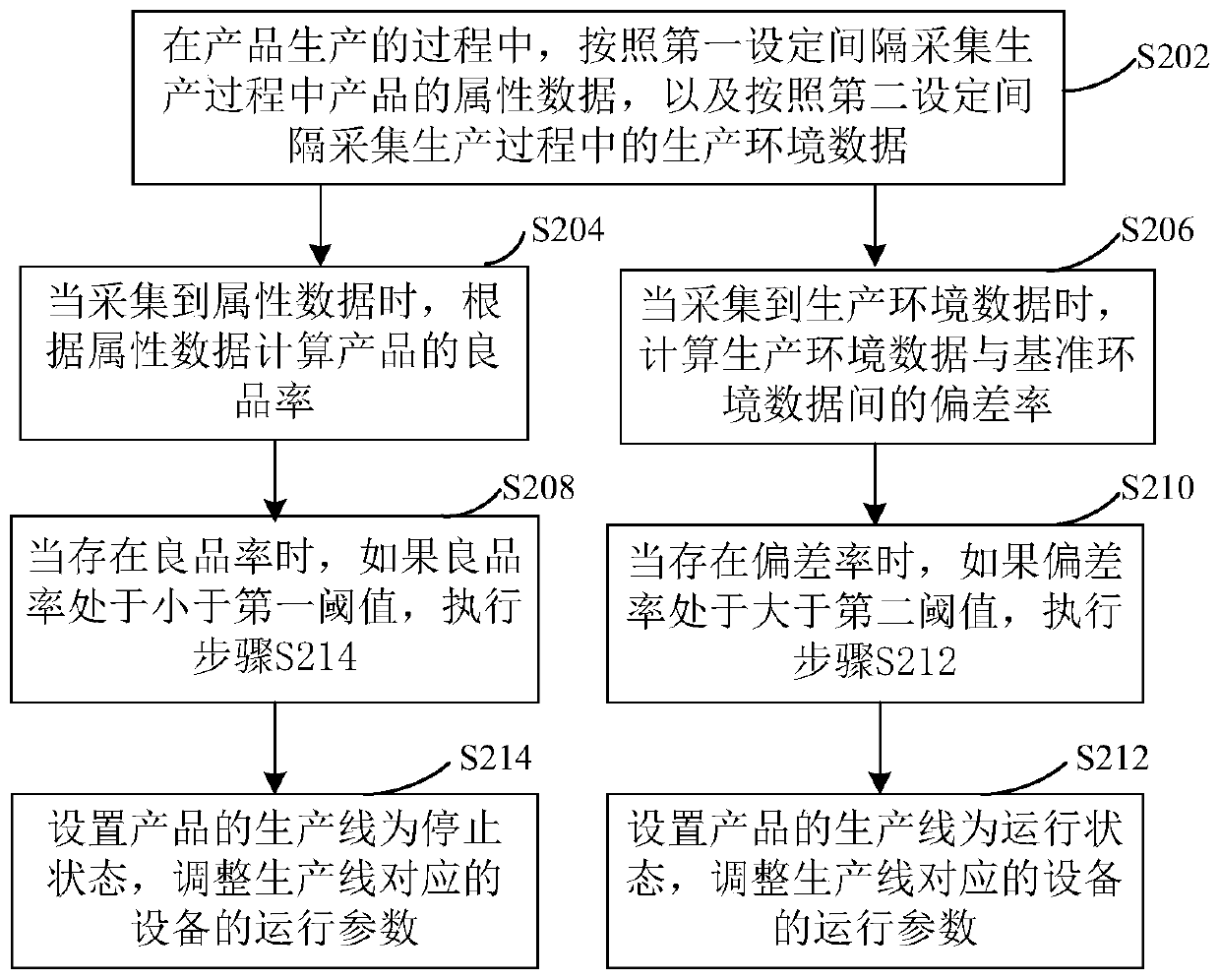

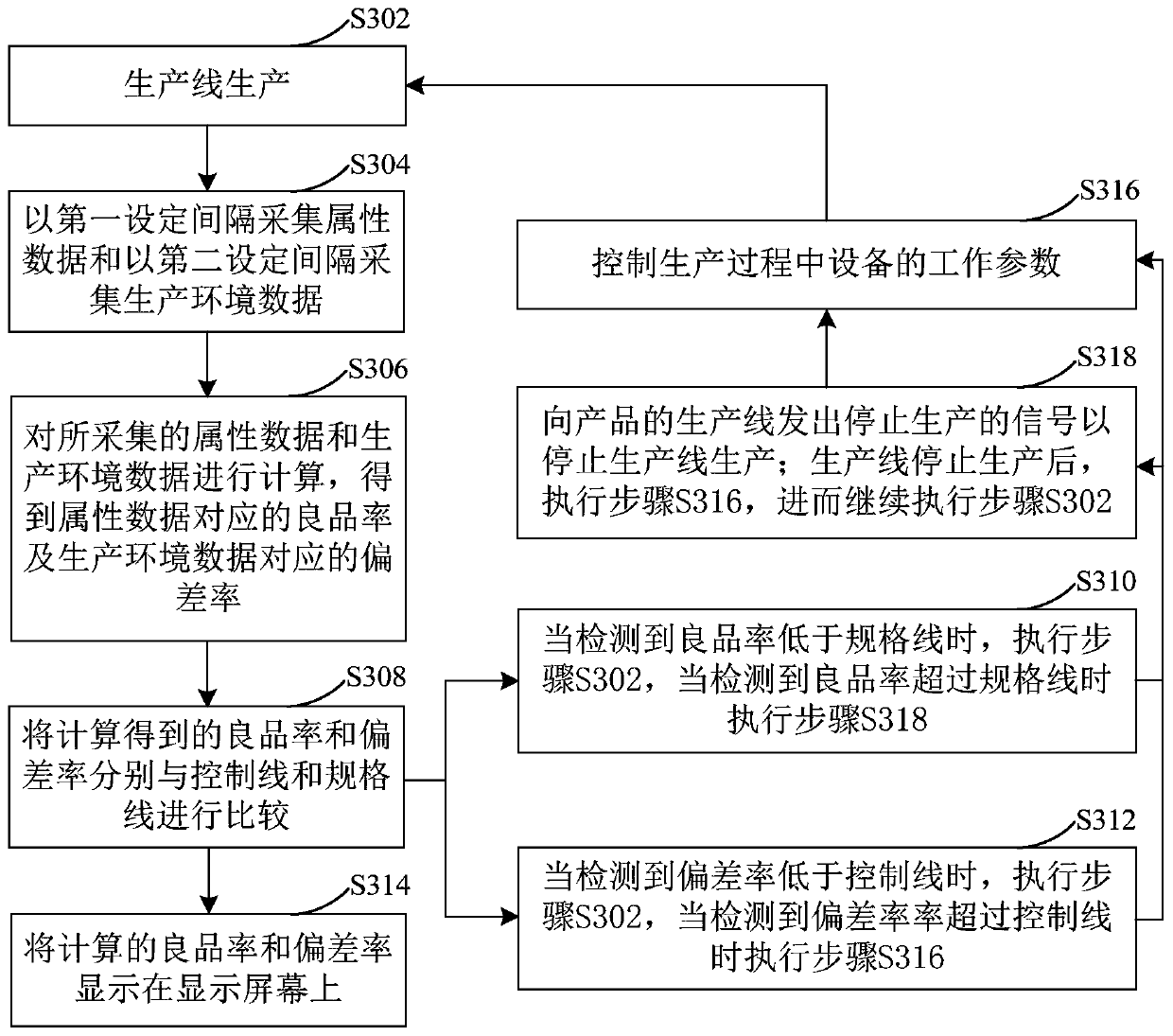

Production monitoring method and device

InactiveCN109976291AMonitor product qualityGuaranteed monitoringTotal factory controlProgramme total factory controlProduction lineAutomatic control

The invention provides a production monitoring method and device, and relates to the technical field of automatic control. The method comprises the following steps: collecting attribute data and production environment data of a product; controlling the working parameters of equipment in a production process according to a yield rate of the product calculated according to the attribute data, so asto adjust the production environment data in the subsequent production process; and controlling the working parameters of the equipment in the production process according to a deviation rate calculated according to the production environment data and reference environment data, so as to adjust the production environment data in the subsequent production process. The monitoring of the product quality, the production environment and the production equipment of a production line is ensured by the manner of calculating the yield rate of the product according to the attribute data and the manner of calculating the deviation rate according to the production environment data; by adoption of the manner of controlling the working parameters of the equipment according to the deviation rate and theyield rate, the working parameters of the equipment in the production process can be adjusted in time, thereby alleviating the problem that the handling of production abnormality is delayed in the production process.

Owner:伟创力电子设备(深圳)有限公司

Base board detector and glass base board detector

InactiveCN1987436AMonitor product qualityIncrease productivitySemiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationMechanical engineeringTest set

The check out test set is assorted to conveying appliance to be used. Possessing transportation face, the conveying appliance is in use for transporting at least one base plate. The check out test set for base plate includes the supporting seat, the uplift mechanism, the light box, and the drive mechanism. The uplift mechanism is setup on the supporting seat. The uplift mechanism possesses multiple pieces of uplift brackets. Being positioned under transporting face, each uplift bracket setup is parallel to the transporting face. Being setup corresponding to the uplift mechanism, the light box is in use for visual inspecting glass base plate. The drive mechanism setup inside the supporting seat is connected to the uplift mechanism.

Owner:AU OPTRONICS CORP

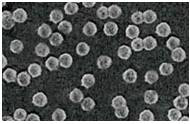

Colorimetric kit for rapidly detecting chicken egg-yolk antibody

ActiveCN109490293ASuperparamagneticMonitor product qualityMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsRoom temperatureDopamine

The invention discloses a colorimetric kit for rapidly detecting a chicken egg-yolk antibody. The colorimetric kit comprises a magnetic molecularly imprinted polymer. The magnetic molecularly imprinted polymer is prepared by the following method steps: 1) preparing Fe3O4 NPs with uniform size; 2) adding the Fe3O4 NPs into Tris buffer, performing ultrasonic dispersion, adding 1-5mg of egg yolk antibody and 2-5mg of dopamine, and mechanically stirring at a room temperature for 6-12 hours; 3) washing, and performing vacuum drying, thereby obtaining the magnetic molecularly imprinted polymer. Themagnetic nano-particle Fe3O4 NPs is prepared by the following steps: dissolving 2.7g of FeCl3*6H2O and 7.2g of NaAc into 100mL of ethylene glycol while intense stirring, sealing, reacting at a high temperature, cooling to a room temperature, and performing magnetic separation so as to obtain black magnetite particles; and washing, and performing vacuum drying, thereby obtaining the magnetic nano-particle Fe3O4 NPs.

Owner:JILIN UNIV

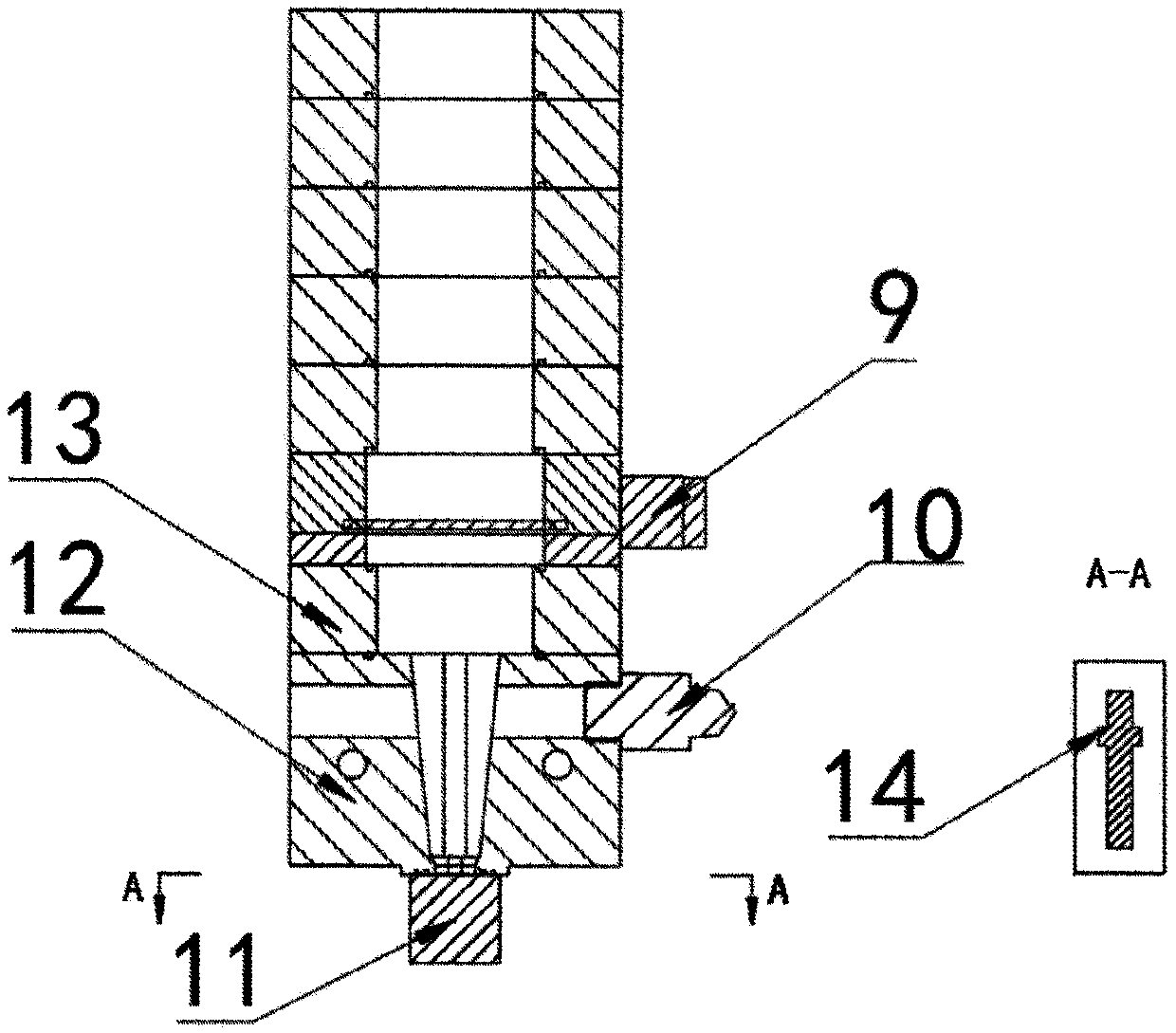

Control method and control system for welding melting amount of electrode at spark plug side

ActiveCN107790862AGet the actual welding melting amount in real timeTimely measurement verificationWelding monitoring devicesMeasurement deviceControl system

The invention belongs to the technical field of welding for electrodes at spark plug sides, and discloses a control method for the welding melting amount of an electrode at a spark plug side, and a control system for realizing the method. The pressure threshold values or values of a pre-welding pressure, a welding pressure and a post-welding pressure are set in a signal control device, through thereal-time acquisition and feedback of a pressure induction device for pressures in a welding process, a signal control device carries out real-time comparison and calculation on the received pressuresignals, and flexibly controls the welding pressures in a pre-welding phase, a welding phase and a post-welding phase, and the welding melting amount of the electrode at the spark plug side is judgedby the welding pressures; and meanwhile, through arrangement for a displacement measurement device and a side electrode post-welding length measurement device, and the respective signal connection for the displacement measurement device and the side electrode post-welding length measurement device with the signal control device, a semi-closed-loop structure carrying out effective monitoring on the welding melting amount is formed as a whole. Therefore, on one hand, the outflow of defective products can be prevented, and on the other hand, a correction prompt role and guidance on equipment orparameters can be realized, product quality can be monitored in real time, and meanwhile, the production efficiency is increased.

Owner:ZHUZHOU TORCH SPARK PLUG CO LTD

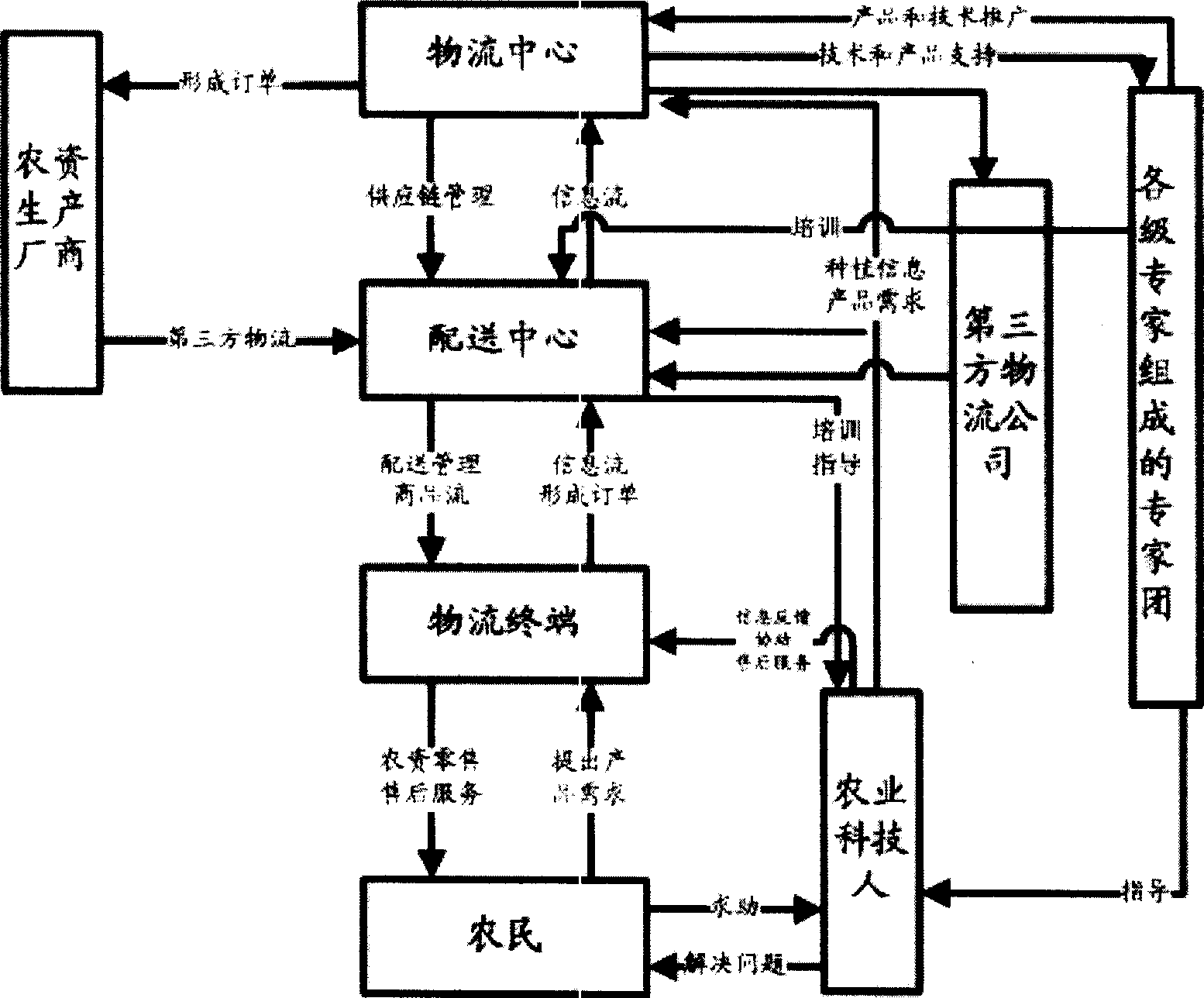

Ternary form agricultural logistics system

The invention discloses a novel agriculture material circulation system, which is a compositive material circulation system composed of 'human net', 'ground net' and 'sky net', and adds development element for the lagging material circulation system of the countryside with cooperation of expert panels and science and technology brokers. It is of marked significance for solving the problems of increasing farmers' income and realizing safety of the primary products, and also provides a novel clew for building novel country of socialism and serviing 'three agricultures'.

Owner:BEIJING BOEN AGRI DEV

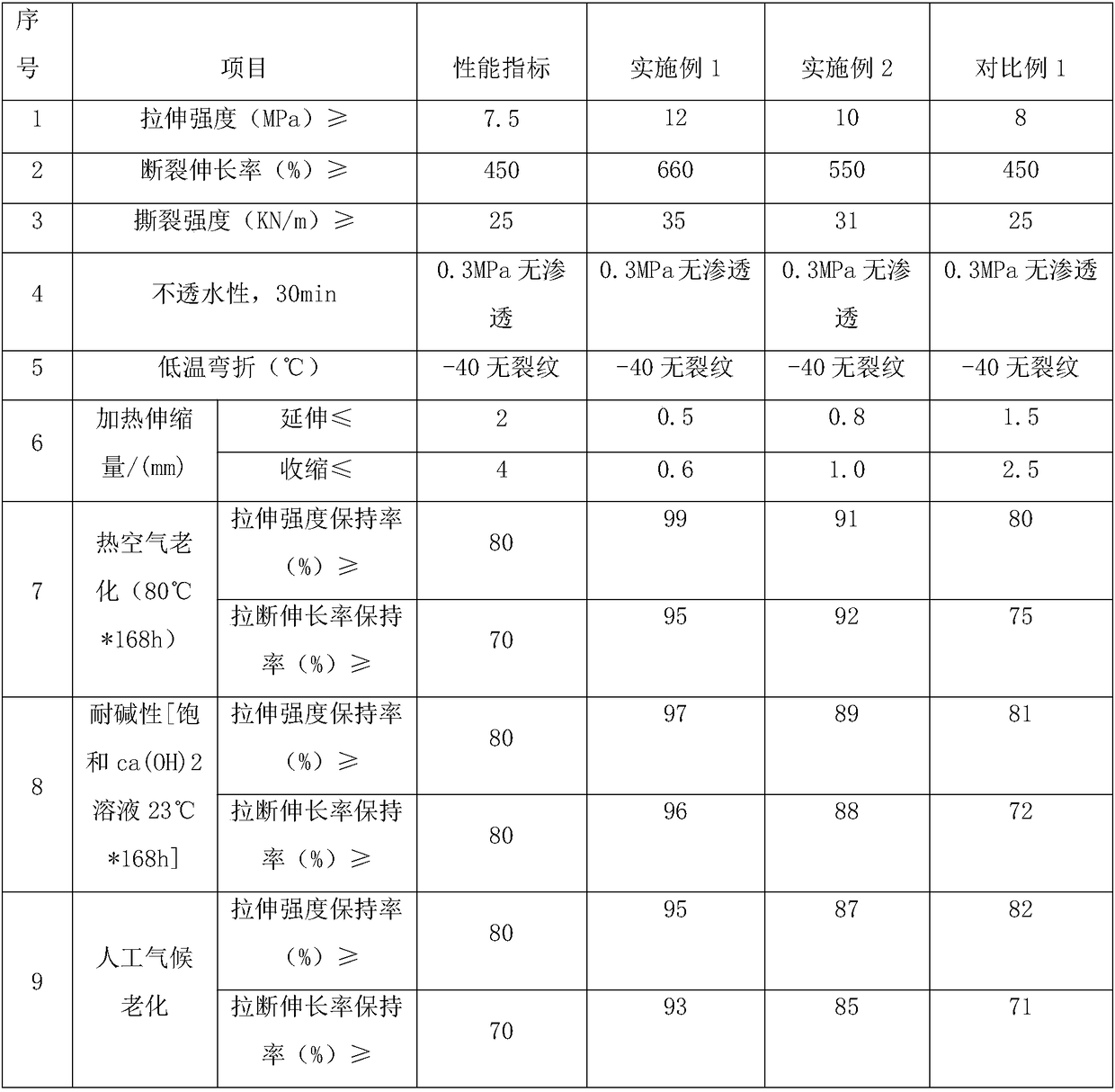

Preparation method of dynamically-vulcanized ethylene propylene diene monomer rubber waterproof coiled material

InactiveCN108127943AThe process is simple and continuousImprove physical and chemical propertiesFlat articlesScrapContinuous production

The invention relates to the field of waterproof coiled materials, and discloses a preparation method of a dynamically-vulcanized ethylene propylene diene monomer rubber waterproof coiled material. According to the preparation method disclosed by the invention, linkage is carried out by adopting two twin-screw extruders, so that the quality of a product can be monitored in real time while continuous production is realized. The preparation method of the dynamically-vulcanized ethylene propylene diene terpolymer rubber waterproof coiled material has the advantages that the production efficiencyis greatly improved, and on-line adjustment of processes and formulas is realized, and a scrap ratio is reduced; and moreover, the prepared dynamically-vulcanized ethylene propylene diene monomer rubber waterproof coiled material is relatively excellent in physical and chemical properties and is stable in quality of the product.

Owner:QINGDAO KEHUA M M M

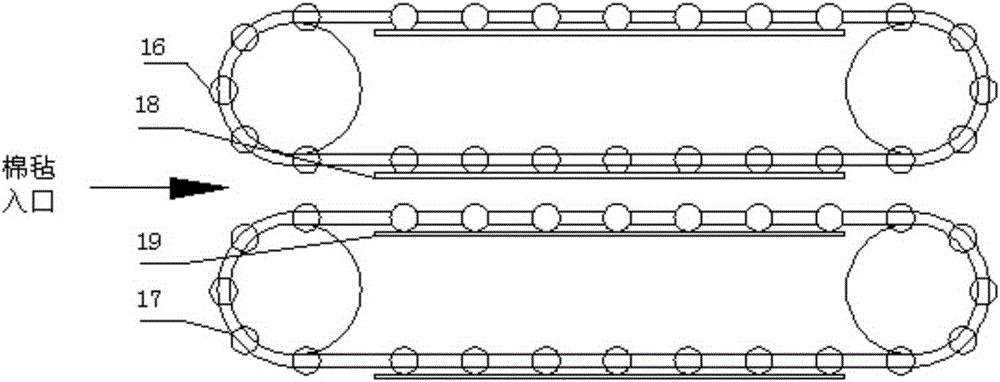

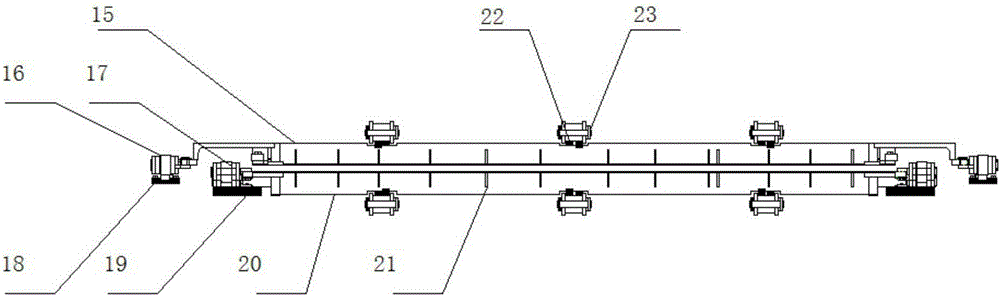

Novel mineral wool solidification device

The invention discloses a novel mineral wool solidification device which comprises an upper chain plate conveying belt, a lower chain plate conveying belt and a hot air furnace, wherein a space between the upper chain plate conveying belt and the lower chain plate conveying belt forms a solidification area; the solidification area is divided into more than two hot air areas in a material conveying direction; a hot air connector is arranged at each of the upper part, the lower part, the left side and the right side of each hot air area; the two hot air connectors of each hot air area are connected with the hot air furnace via two air inlet pipes respectively; and the other two hot air connectors are communicated with the outside world via two air return pipes respectively. The novel mineral wool solidification device avoids scorching of the upper surface and the lower surface of a wool plate, improves a solidification effect, prevents collapse of chain plates, and can be used for production of a mineral wool product with volumetric weight of 20-400kg / m<3>.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

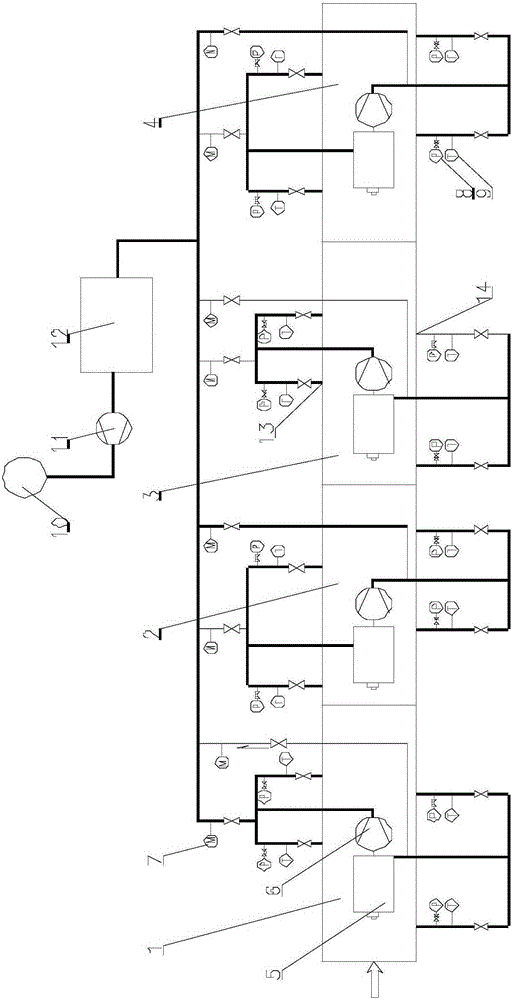

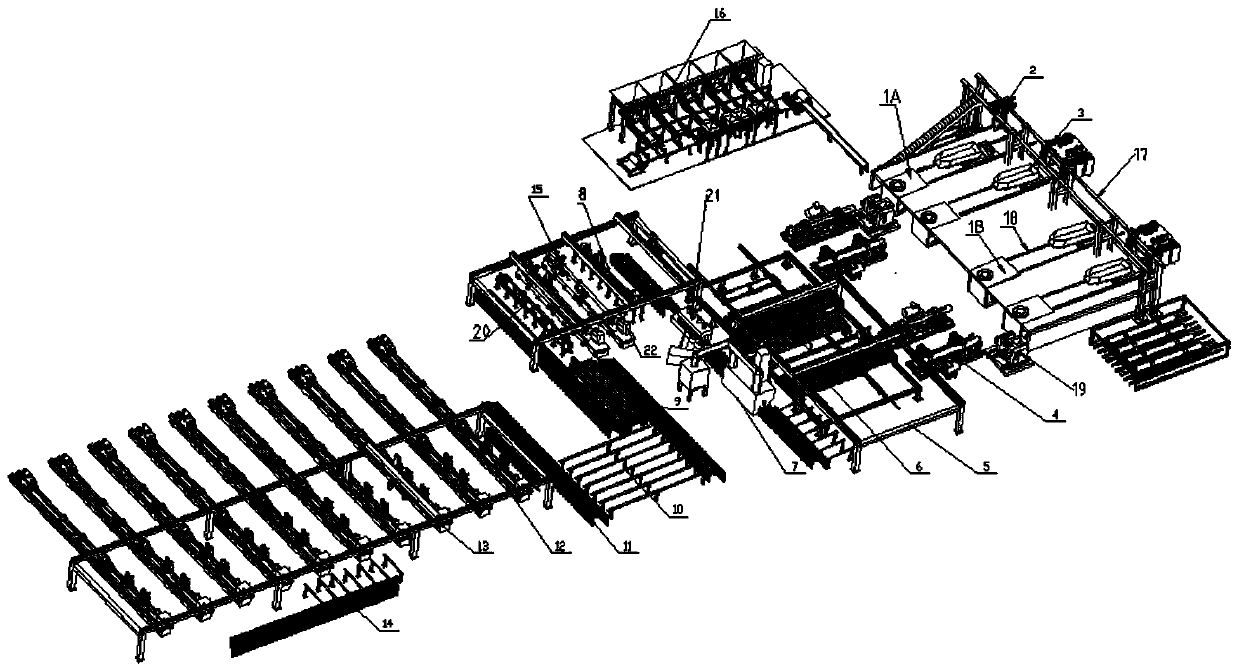

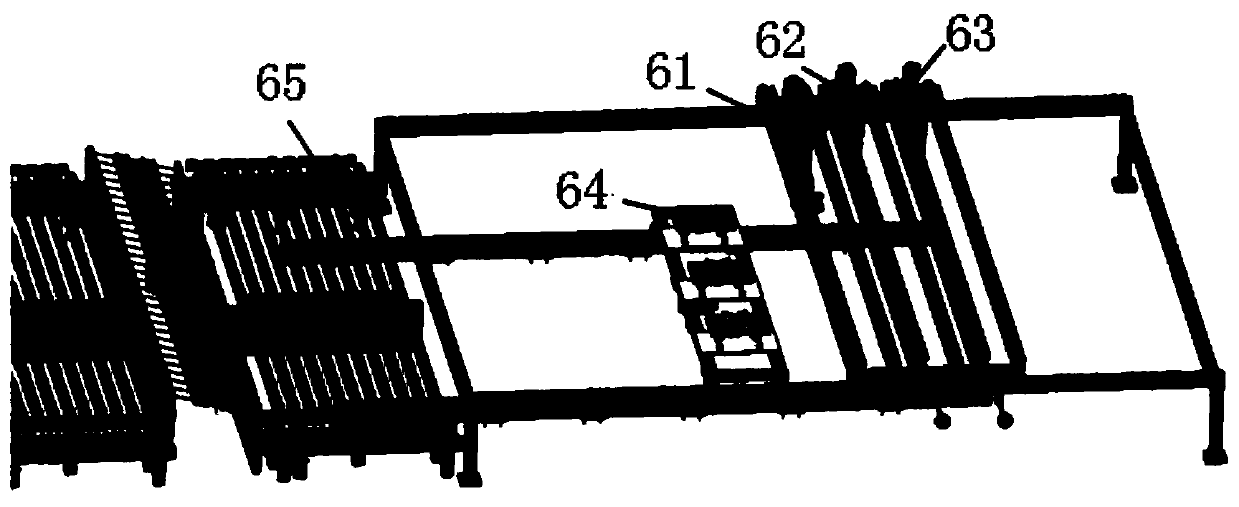

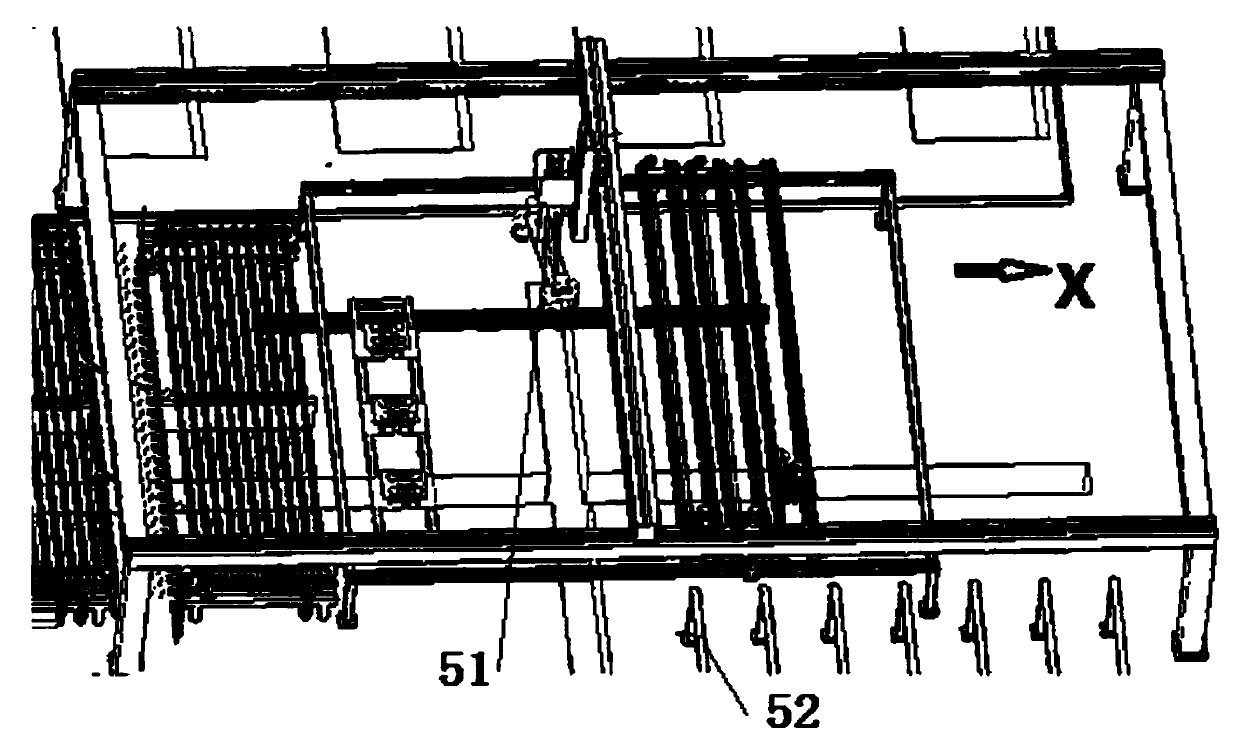

Automatic production line and production manner of centrifugal cast pipes

PendingCN109926574AAvoid damageFully automatedCasting plantsMolten metal supplying equipmentsEngineeringSmelting

The invention discloses an automatic production line and a production manner of centrifugal cast pipes. The automatic production line comprises a batching library. A feeding device is arranged at oneend of the batching library. The feeding device comprises a feeding robot, four feeding trolleys, first rails for supporting the feeding robot, and second rails for supporting the feeding trolleys. Asmelting device is arranged at the other ends of the second rails, a pipe pulling robot is arranged at the other end of the smelting device, and a steering robot is arranged at the other end of the pipe pulling robot. The steering robot comprises a rotary robot and a sliding rail, a shot blasting machine and a straightening machine are arranged on the other side of the sliding rail, and a head cutting device is arranged at the other end of the straightening machine. The head cutting device comprises a transfer cutting head, a double-head lathe, a laser marking machine and a transfer robot. A PT pond is mounted on one side of the laser marking machine, a transfer passageway is formed in the other side of the PT pond, a first transfer frame is arranged at the other end of the transfer passageway, a boring mill robot is arranged on the other side of the first transfer frame, a boring mill is arranged below the boring mill robot, and a second transfer frame is arranged at the other end ofthe boring mill.

Owner:SHANGHAI SUPEZET ENG TECH CO LTD +1

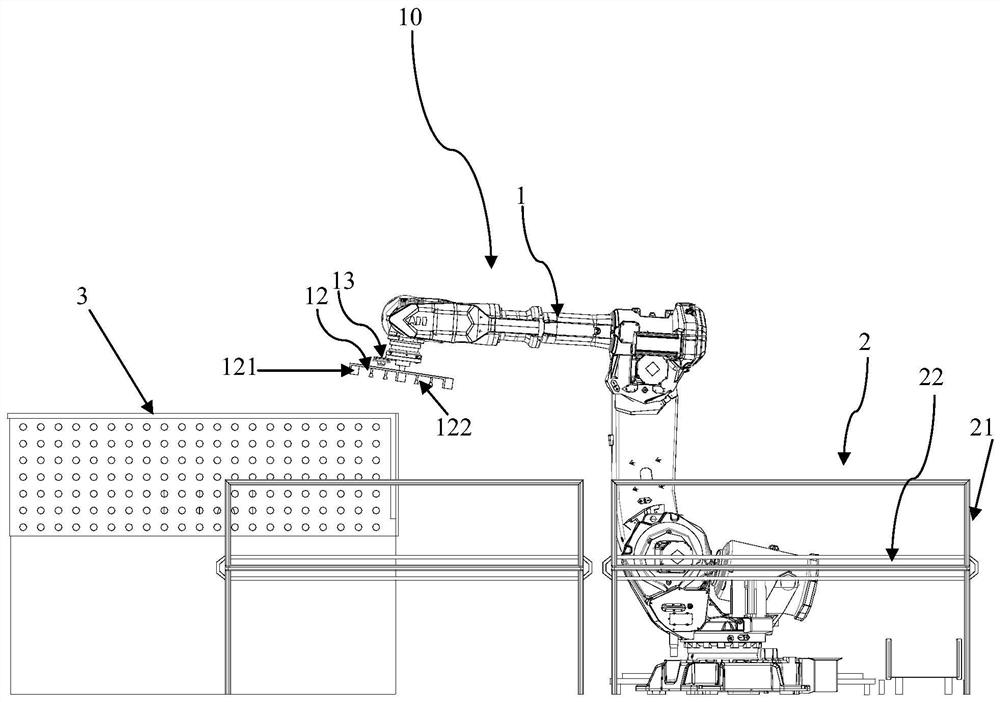

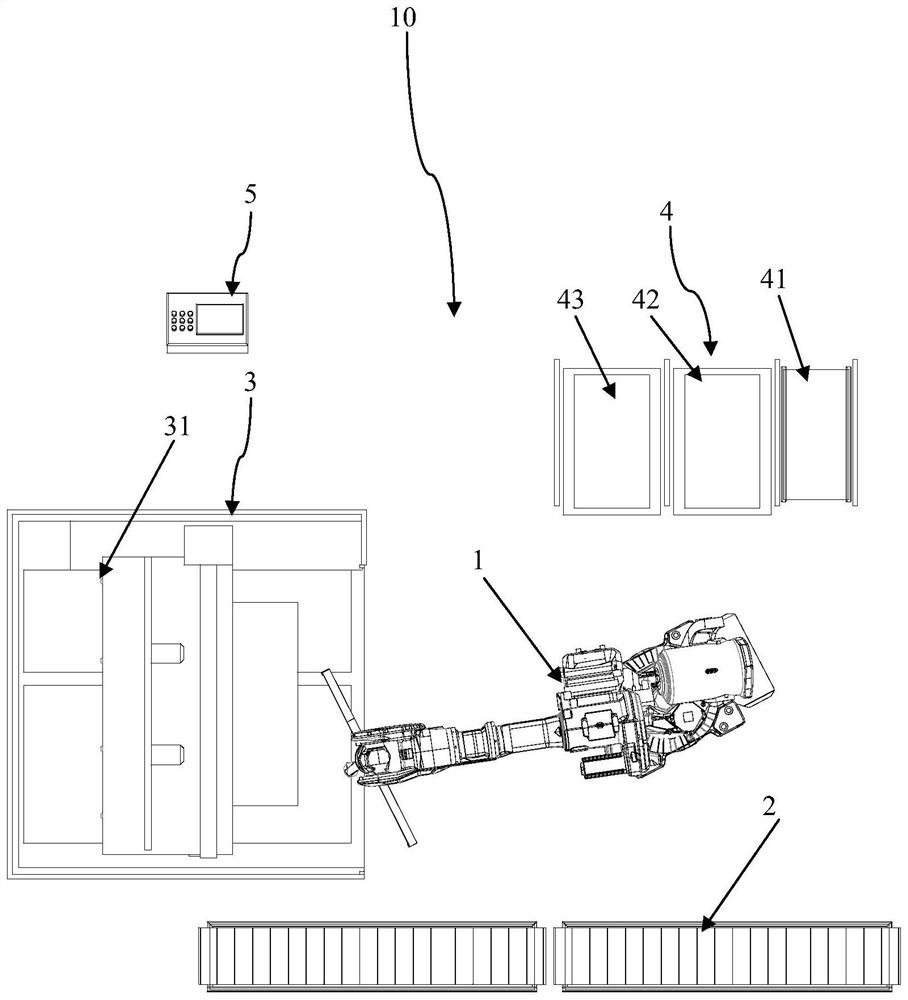

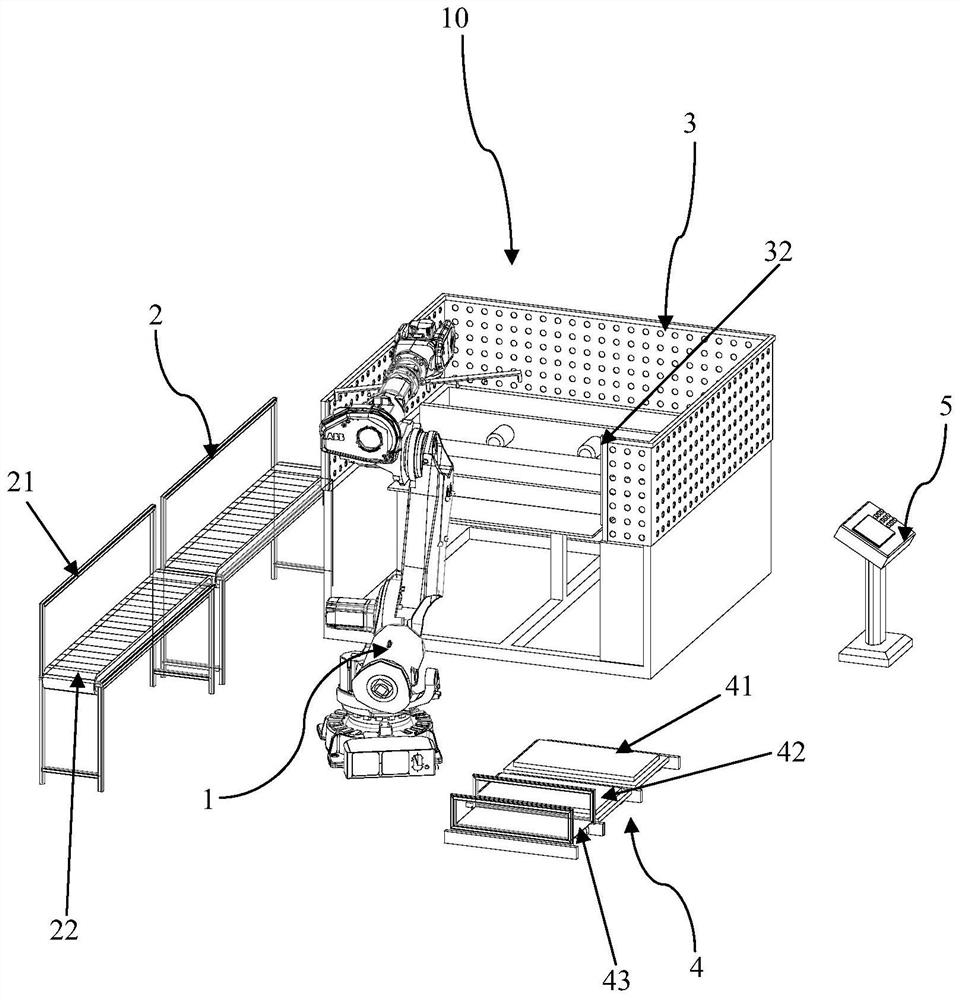

Detecting, bending and feeding device and method for two-device assembly

PendingCN113385434AMonitor product qualityEasy to check and rectifySortingControl engineeringProcess engineering

The invention provides a detecting, bending and feeding device and method for a two-device assembly. The device comprises a carrying device, a material conveying system, a bending machine, a material placing platform and a console, the carrying device comprises a robot, and the robot is provided with a grabbing system and a visual detection device. A preset program capable of controlling the robot is arranged in the console, and the console can control the moving track of the robot, control the grabbing system to grab and place the materials, control the visual detection device to detect the sizes of the materials and control the material conveying system and the bending machine to be started and stopped. According to the device and method, automatic detection of the two-device assembly is achieved through the robot and the visual detection device, the detection proportion is increased, the overall quality is controlled, automatic taking, placing, bending and feeding of the two-device assembly and a calcium-plastic plate are achieved through the robot, the clamping device and the suction cup assembly, the production efficiency is effectively improved, and through layout design, new and old process production can be considered, and the space is saved.

Owner:GREE ELECTRIC APPLIANCES WUHAN +1

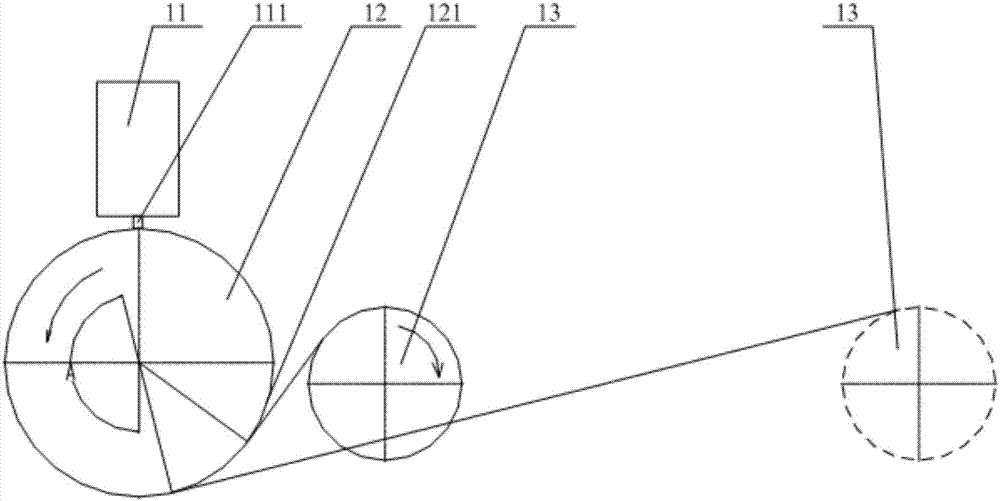

Amorphous strip forming device

The invention discloses an amorphous strip forming device. The amorphous strip forming device comprises a strip spraying bag. A nozzle is arranged at the bottom of the strip spraying bag. A cooling roller is rotationally arranged below the nozzle in a fixed-axis manner. A grabbing device is arranged on one side of the cooling roller, and the movement direction of a top blanking forming position of the cooling roller is directed at the side away from the grabbing device. A stripping device matched with a strip is arranged on the cooling roller. The amorphous strip forming device is good in amorphous strip cooling forming effect and is low in energy consumption, and the product qualification rate and the yield of the device are high.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

Laser welding jig and method for lithium battery cell positive and negative pole pieces and lead-out pole lugs

ActiveCN110153558AAvoid lossEliminate deformationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPole piece

The invention discloses a laser welding jig and method for lithium battery cell positive and negative pole pieces and lead-out pole lugs. According to the laser welding jig and method for the lithiumbattery cell positive and negative pole pieces and the lead-out pole lugs, welding is performed adopting a laser welding manner, product deformation is eliminated, and the welding quality and the appearance attractiveness are improved; in the welding process, no contact exists between a welding head and a welded product, equipment has no parts worn and torn easily, and the maintenance cost is low;and the product is fixed through gas pressure, and welding mistake caused by moving of the product in the welding process is prevented. By means of the laser welding jig and method for the lithium battery cell positive and negative pole pieces and the lead-out pole lugs, the product with attractive molded appearance can be welded and formed, the cost is saved, furthermore, loss of the welding head and the jig is avoided, and meanwhile, the product quality can be monitored.

Owner:深圳市德龙智能高科技有限公司

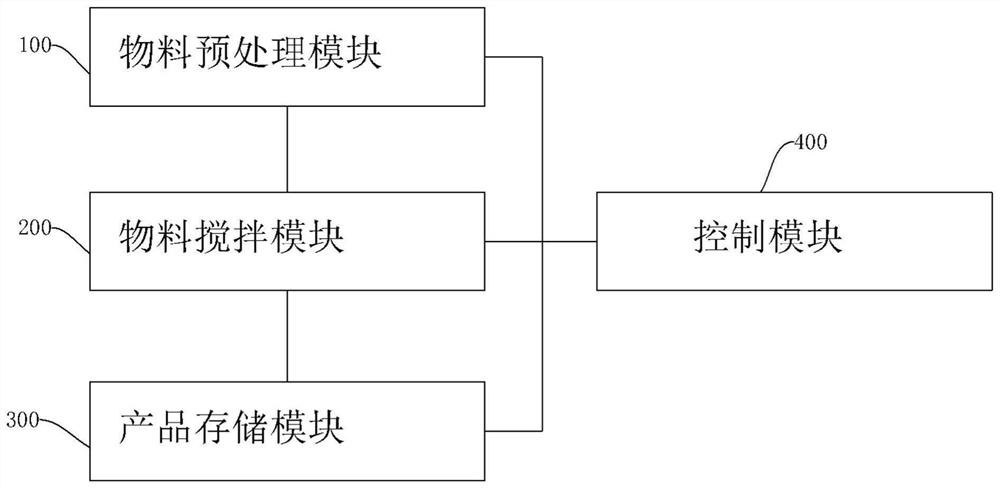

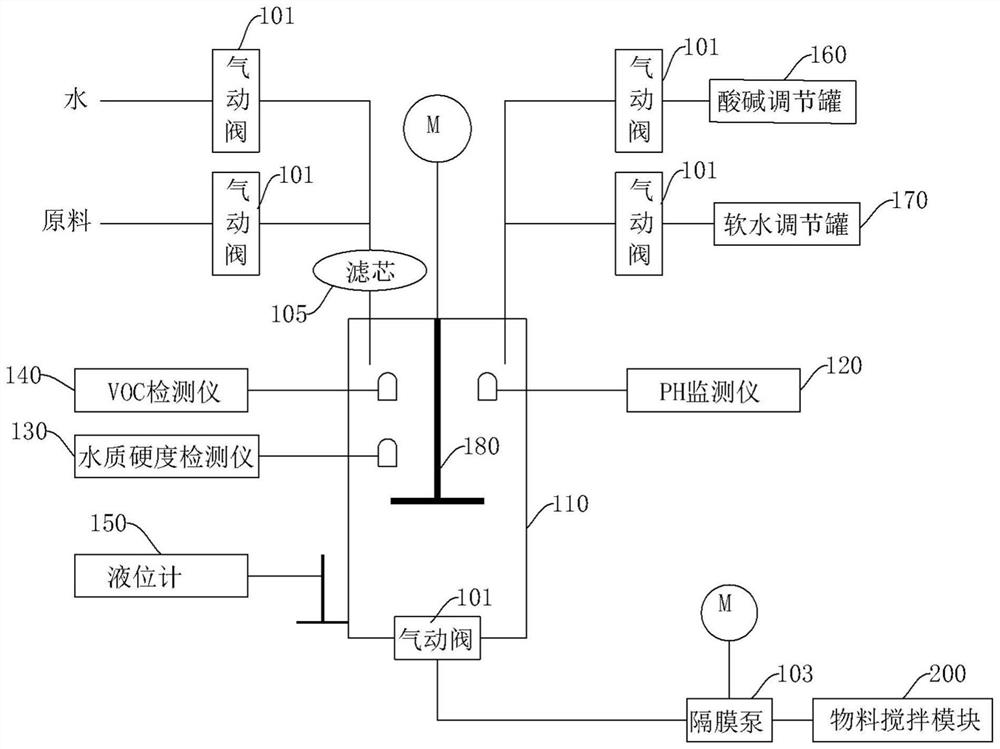

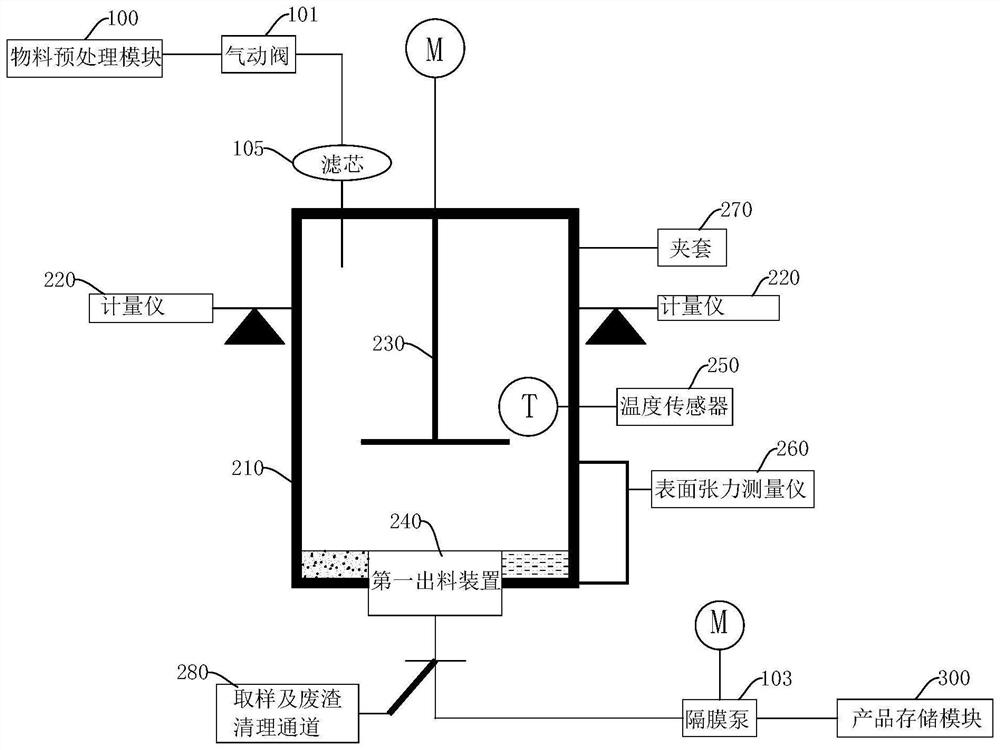

Intelligent batching system for release agent

ActiveCN114558472AAccurately control the dosageQuality improvementTransportation and packagingMixer accessoriesProcess engineeringPre treatment

The invention discloses an intelligent batching system for a release agent, and relates to the field of concrete cement products and components. The intelligent batching system for the release agent comprises a material pretreatment module, a material stirring module, a product storage module and a control module, wherein the control module is respectively connected with the material pretreatment module, the material stirring module and the product storage module; the material pretreatment module is used for monitoring and pretreating raw materials and water quality, and the material stirring module is connected with the material pretreatment module and used for stirring the water and the raw materials according to a preset proportion and monitoring the quality of the water and the raw materials; the product storage module is connected with the material stirring module and is used for storing the stirred mixture and carrying out quality monitoring; the control module is used for collecting, calculating and regulating data of the material preprocessing module, the material stirring module and the product storage module, standardization of the raw material dosage in the release agent using process can be achieved, the product quality is monitored in real time, and the product using consistency is ensured.

Owner:四川省简阳天府脱模材料有限公司

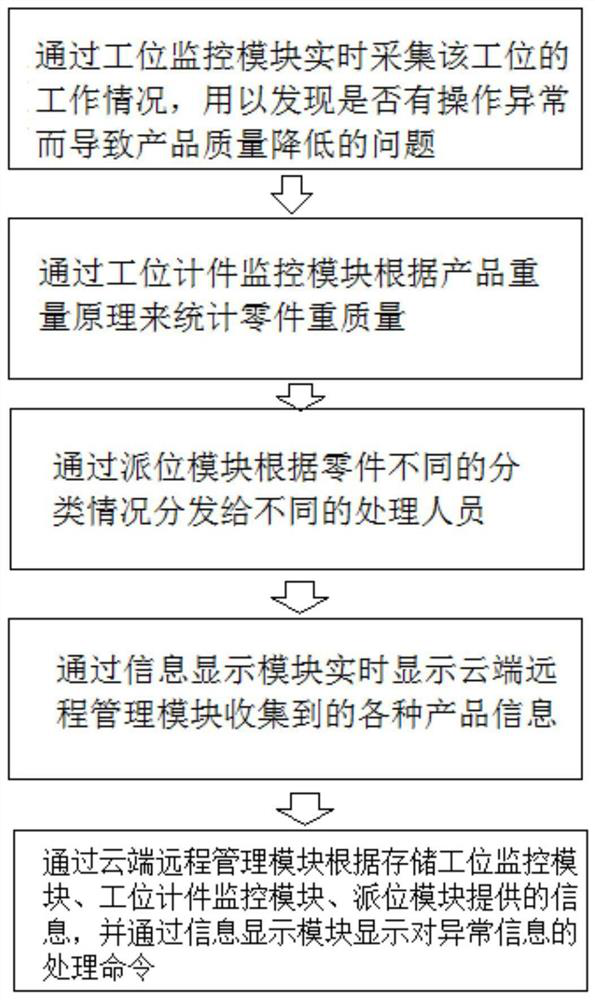

Production line station management system and method

InactiveCN112488515ARapid responseMonitor productionInterprogram communicationResourcesManufacturing lineManagement system

The invention discloses a production line station management system, which is characterized by comprising a cloud remote management module, a station monitoring module, a station piece counting monitoring module, a station dispatching module and an information display module; the station monitoring module, the station piece counting monitoring module, the position sending module and the information display module are all connected with the cloud remote management module. The system is quick in response, and can comprehensively monitor the production condition of the product and monitor the quality of the product in real time. The invention further provides a production line station management method.

Owner:西安万木春信息技术有限公司

Method for determining content of free chromium in chromium chelate preparation by using ion exchange chromatography

InactiveCN106501384ALower requirementEasy to operateComponent separationIon chromatographyIon exchange

The invention provides a method for determining the content of free chromium in a chromium chelate preparation by using ion exchange chromatography. The method comprises the following steps: adding a solution of a chromium chelate preparation sample into a cation exchange chromatographic column; eluting unadsorbed chromium chelate with deionized water; then eluting free chromium with a highly acid solution; and calculating the content of free chromium in the chromium chelate preparation. The method is simple to operate and has low requirements on experimental apparatuses; ion exchange resin can be repeatedly used; and the method has good reproducibility and stability, good precision, high accuracy and low detection limit, as low as 1 ppm, and is beneficial for further monitoring of the quality of the feed additive the chromium chelate preparation and for animal culture and food safety.

Owner:HUBEI SHENZHOU CHEM +2

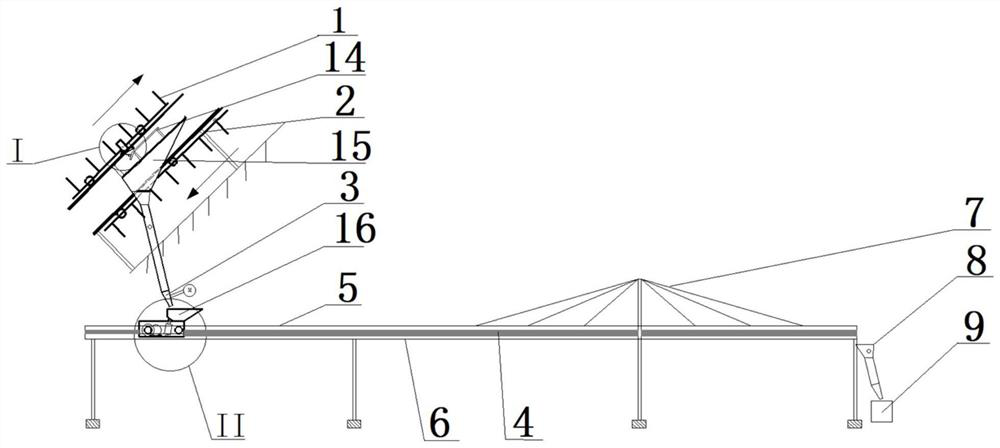

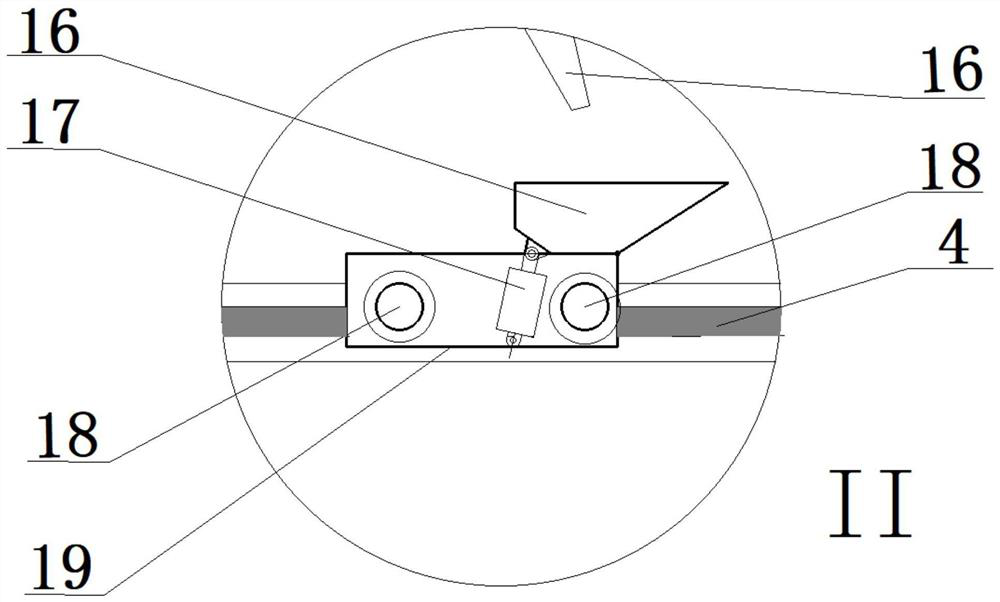

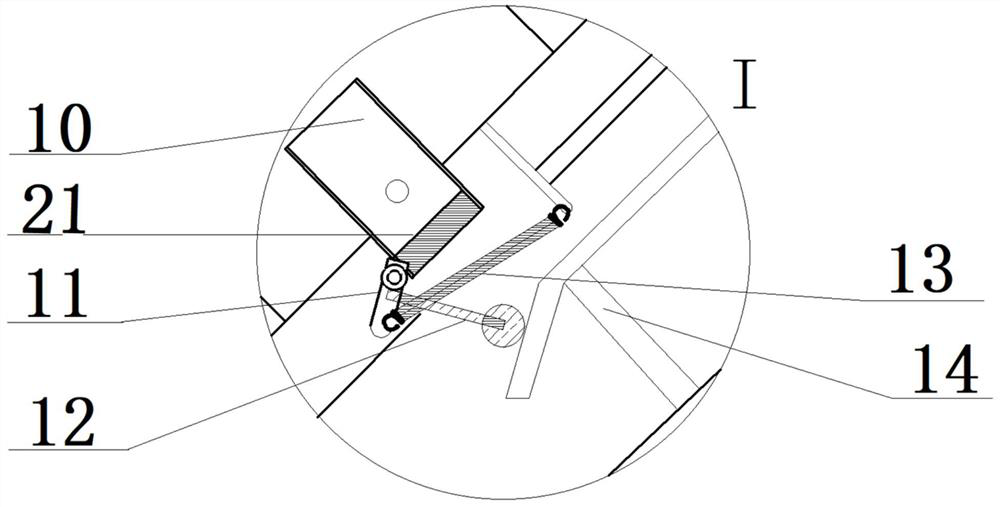

Intelligent sampling and conveying device

PendingCN112393948AReduce equipment input costsLow input costWithdrawing sample devicesStructural engineeringIndustrial engineering

The invention discloses an intelligent sampling and conveying device which structurally comprises a rail mechanism, an automatic sampling device, an intelligent conveying device and an automatic sample unloading device; the rail mechanism is composed of a rail, a rail support, a slide wire and a rain cover, and the automatic sampling device is composed of a sampling box, a discharging scraper-trough conveyer and a gate valve. The intelligent conveying device is composed of a moving trolley and a material receiving hopper, and the automatic sample unloading device comprises a hydraulic push rod, a discharging hopper and a collecting container.

Owner:吉林金隅冀东环保科技有限公司

Method for removing impurity compounds in lidocaine and obtained product

PendingCN114644570ASolid research baseEasy to detectOrganic active ingredientsCarboxylic acid amide separation/purificationImpurityAcetone

The invention discloses a method for removing impurity compounds in lidocaine and an obtained product, and the method comprises the following steps: using or not using inert gas protection, using hydrogen chloride gas to adjust the pH value of a reaction liquid system of lidocaine, hydrochloric acid and acetone to 2.5-3.8, and then separating and purifying. Wherein the lidocaine comprises a compound as shown in a formula II in the specification. According to the method, lidocaine can form hydrochloride and / or hydrate to improve water solubility and bioavailability, a small amount of newly found impurity compounds in lidocaine can be effectively removed, impurity limit control is carried out on lidocaine, and then it is guaranteed that the quality of a raw material medicine product is controllable; moreover, the process conditions are mild, the obtained product is high in yield and purity, low in impurity content, small in toxic and side effects and higher in safety, and the safety, effectiveness and stability of lidocaine hydrochloride (and / or hydrate thereof) and a preparation thereof can be remarkably improved.

Owner:SHANGHAI VIWIT PHARMA CO LTD

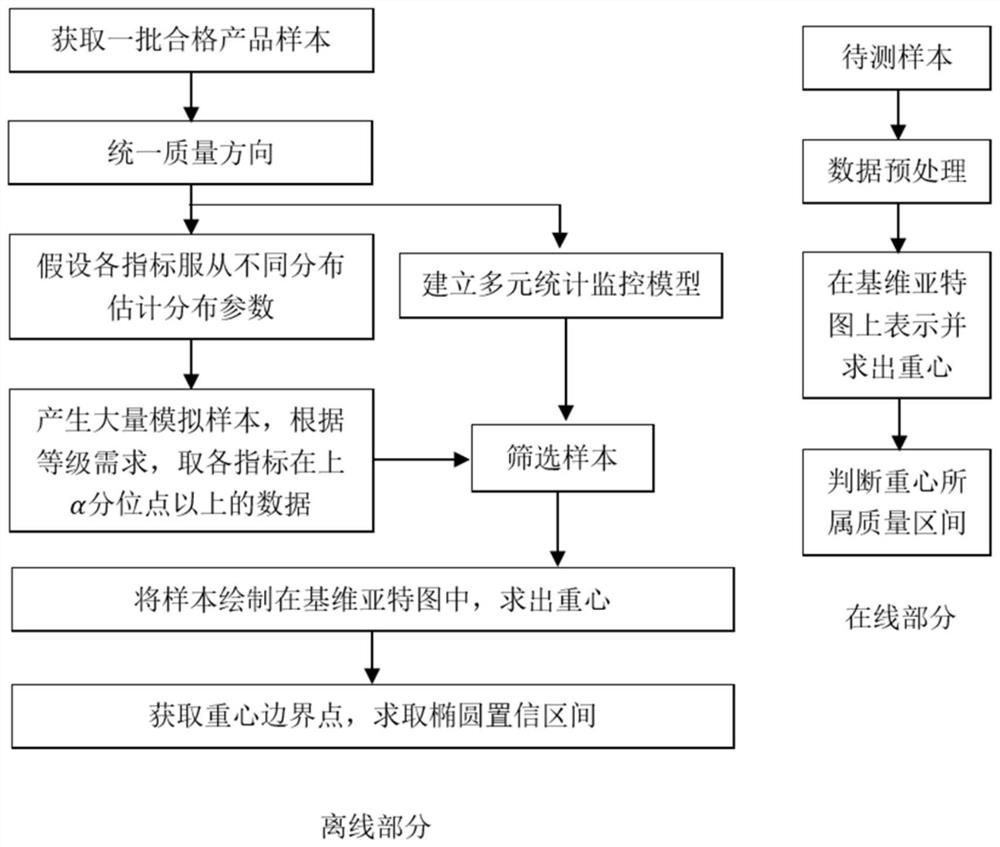

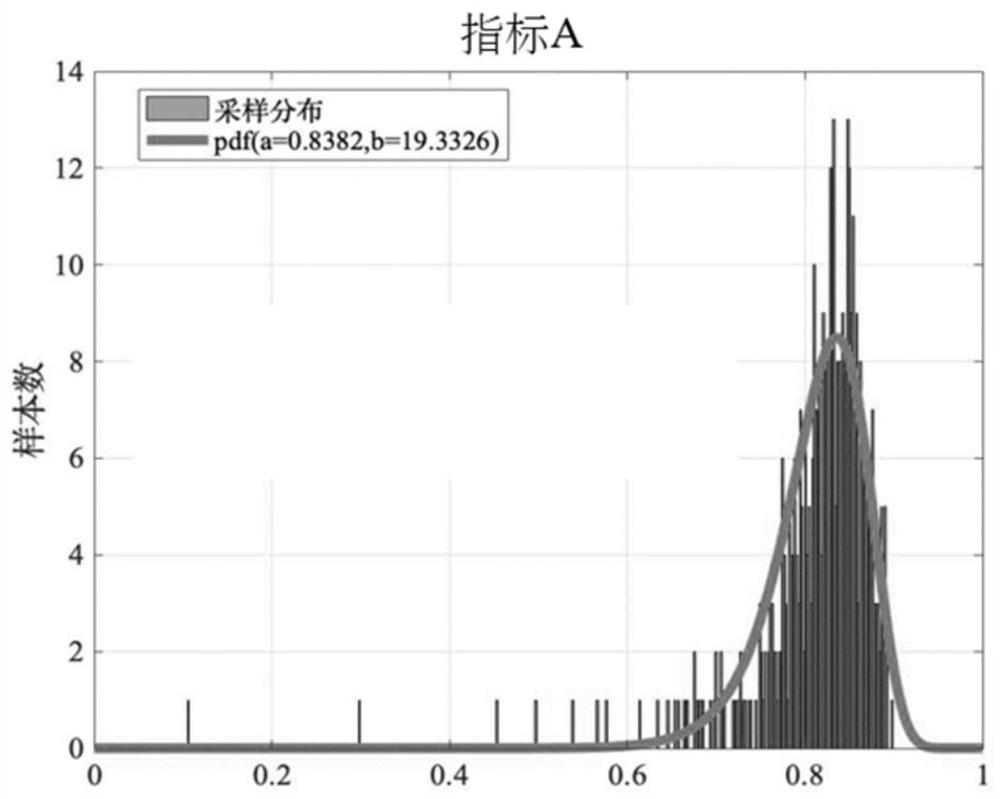

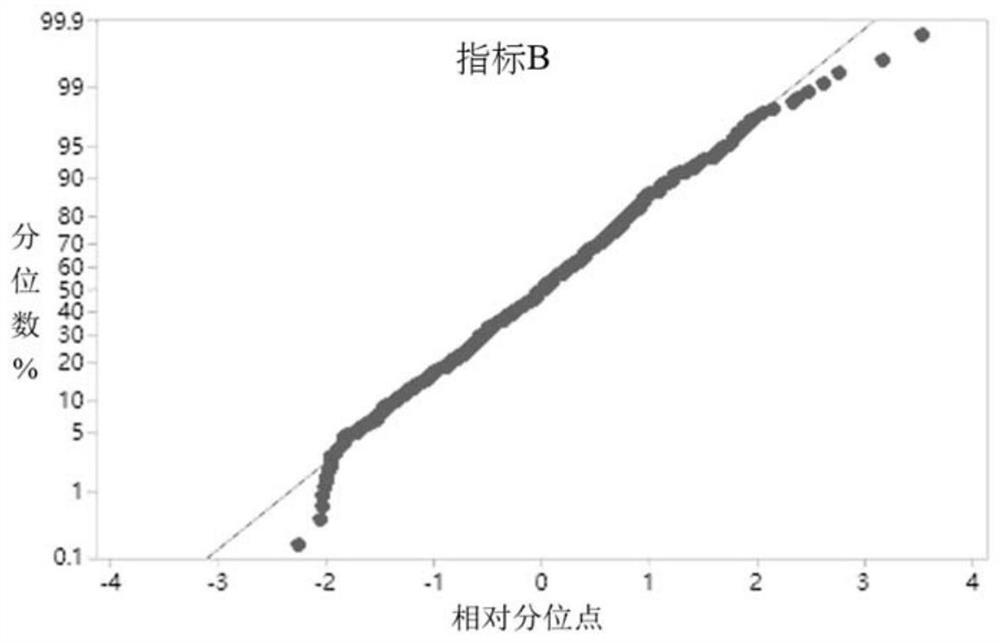

Visual quality grading method and system for multi-index industrial products

PendingCN111985826AAccurate and effective formulationMonitor product qualityResourcesMultivariate statisticalStatistical analysis

The invention discloses a visual quality grading method and system for multi-index industrial products and belongs to the field of quality monitoring of industrial products. According to the method, amodeling method based on multivariate statistical analysis is adopted, a direction with a large multivariate data variance is selected to represent the correlation information, division is carried out to obtain the principal component space and the residual error space, statistics are respectively constructed for monitoring, the correlation information among different indexes can be brought intoa detection range under the condition that the number of measurement indexes is large, and grading standards can be accurately and effectively formulated and the product quality can be monitored for the multi-index industrial product. According to the method, the grading boundary is determined by using the Bayesian diagram, the main correlation information can be reserved, the method is intuitiveand efficient, and quality monitoring efficiency is improved; distribution characteristics of each index are extracted by utilizing a maximum likelihood estimation method, and a large number of randomsamples are generated according to the distribution characteristics, so possible quality grading range loss under the condition that the number of historical data is relatively small is avoided, andgrading accuracy is further ensured.

Owner:HUAZHONG UNIV OF SCI & TECH

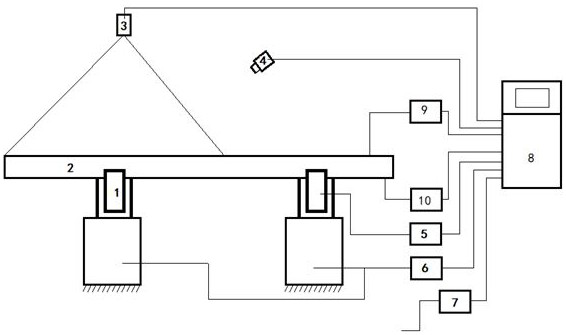

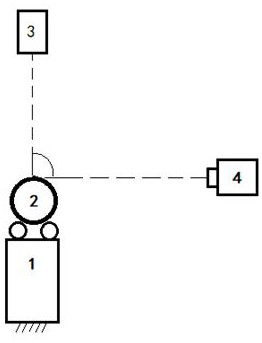

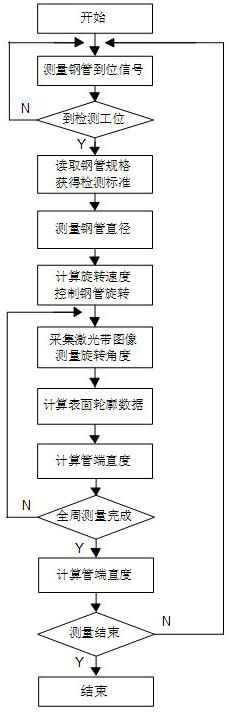

Method and device for measuring straightness of pipe end of steel pipe

ActiveCN113446966AMeet production testing needsAccurately measure true straightnessUsing optical meansEngineeringErbium lasers

The invention discloses a method and a device for measuring straightness of a pipe end of a steel pipe. The device comprises a laser (3), an industrial camera (4), an angle sensor (5), a rotation controller (6) and a straightness calculation unit (8); the laser is arranged right above the steel pipe and projects strip-shaped laser to the surface of the steel pipe to form a light strip curve, and the steel pipe is controlled by the rotation controller to rotate all around during measurement. According to the method, the industrial camera collects thecontour image of a light band curve and sends the contour image to the straightness calculation unit, the angle sensor collects the current angle of the steel pipe and sends the current angle to the straightness calculation unit, the straightness calculation unit calculates single straightness values, and the maximum value of all the single straightness values is the straightness value of the pipe end; according to the invention, the curve parameters are extracted through the light band curve formed by irradiating the surface of the steel pipe with the laser to calculate the straightness of the pipe end of the steel pipe, and more accurate measurement is realized by setting 360-degree all-round rotation, so that the measurement efficiency and precision of the straightness of the pipe end are improved, and the quality monitoring of the steel pipe is facilitated.

Owner:BAOSHAN IRON & STEEL CO LTD

Monitoring Method of Commodity Logistics Environment Based on Smart Contract and Fog Computing

ActiveCN109087005BEasy accessRelieve pressurePayment protocolsResourcesLogistics managementFog computing

The invention discloses a monitoring method of a commodity logistics environment based on smart contracts and fog computing, which is characterized in that the user identity and authority are identified through the fog node module; the commodity sales route is set through coding, and the commodity storage environment is set through smart contracts Threshold to standardize the commodity circulation process; regularly collect commodity status information through sensors, perform Hash calculations, store and upload the calculation results to the blockchain, and store status information locally and in the database to monitor commodity circulation status and product quality; Link to each product through the anti-counterfeiting code, and query the circulation information and status information of the product. The invention can monitor the circulation chain and product quality of the entire commodity circulation link, notify the whole network of unqualified product information, and solidify the evidence.

Owner:HEFEI UNIV OF TECH

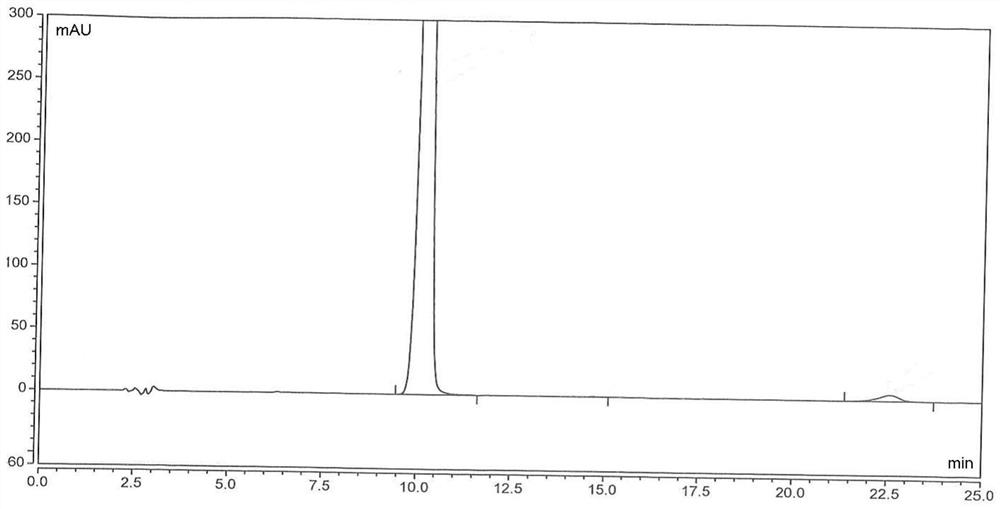

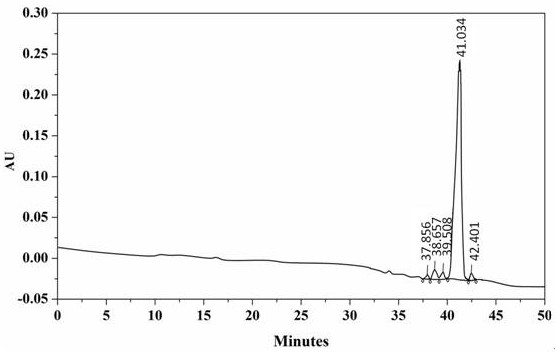

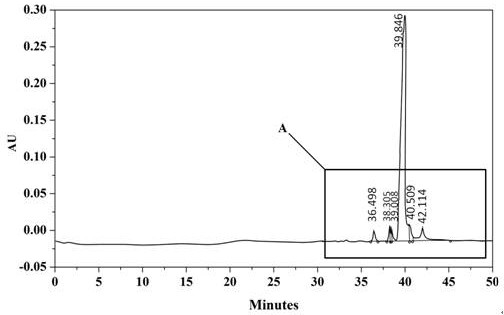

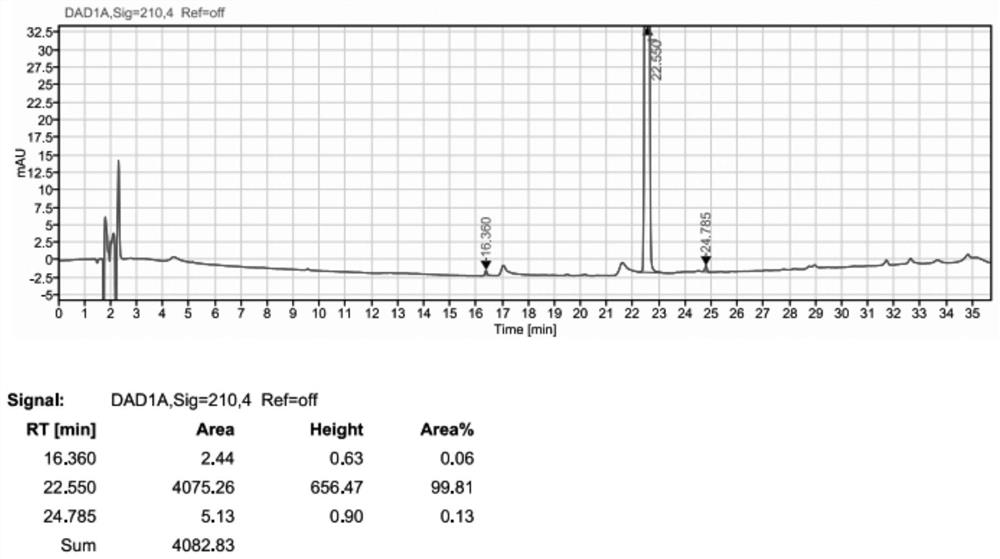

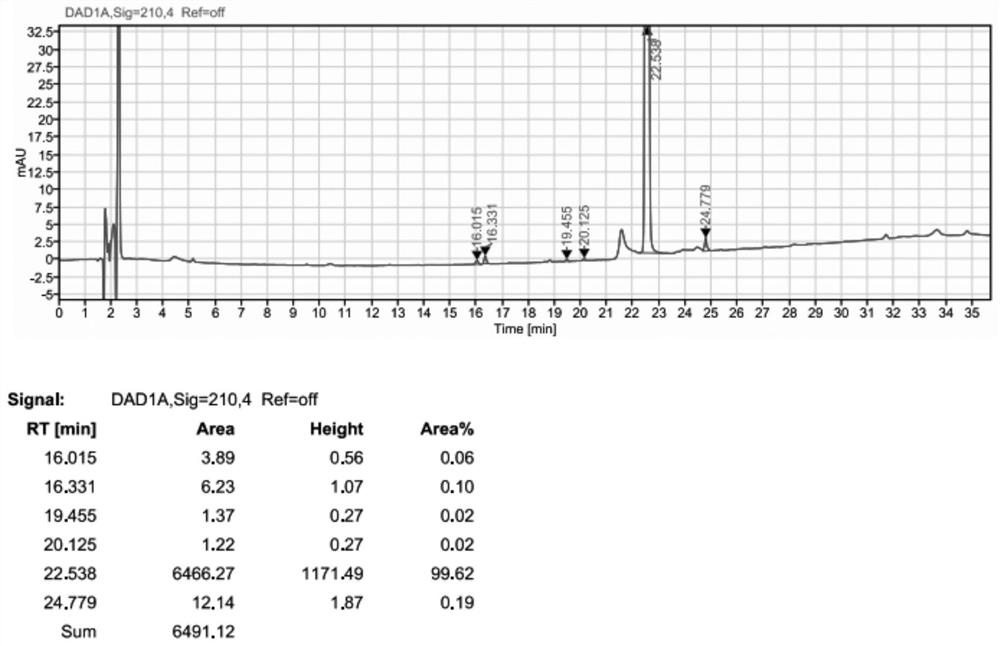

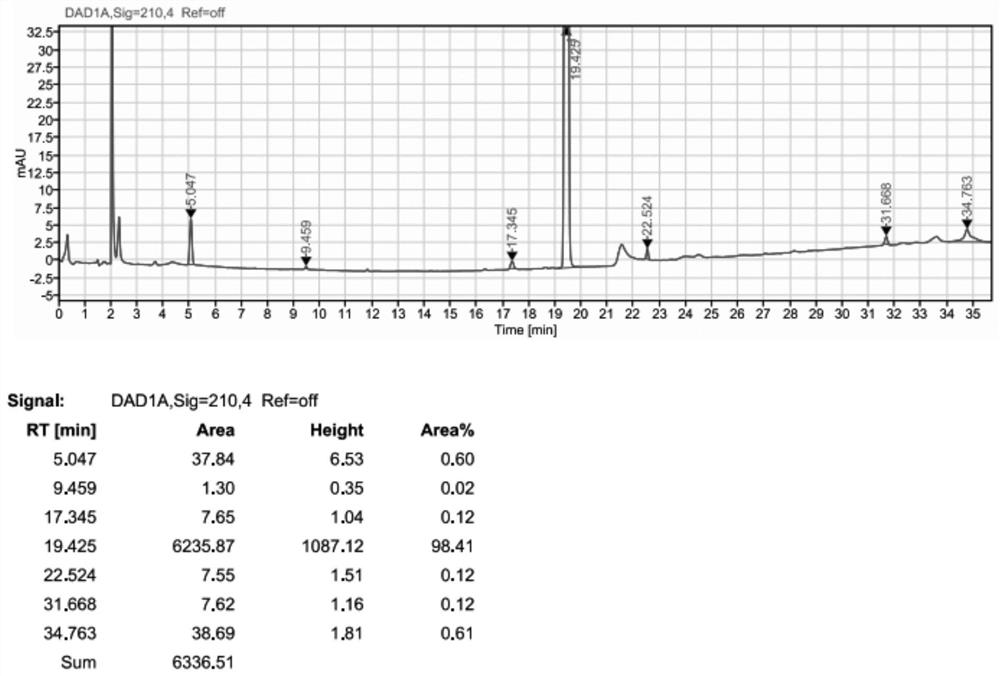

Ultra-high performance liquid chromatography analysis method of semaglutide

ActiveCN113960223ALarge specific surface areaImprove permeabilityComponent separationChromatographic columnPyrimidine

The invention discloses an ultra-high performance liquid chromatography analysis method of semaglutide, and relates to the technical field of polypeptide quality analysis, a chromatographic column filler in ultra-high performance liquid chromatography comprises a core-shell type filler which is surface-bonded core-shell type SiO2 microspheres; the compound for surface bonding comprises at least octadecyl trichlorosilane; the aperture of the chromatographic column filler is 16-20 nm; a preparation method of the core-shell type SiO2 microspheres in the surface-bonded core-shell type SiO2 microspheres is a polymerization induced colloid coagulation technology; a used template comprises novel urea resin, and raw material components of the novel urea resin comprise urea, formaldehyde and 2-aminopyrimidine-5-formaldehyde hydrate. According to the ultra-high performance liquid chromatography analysis method provided by the invention, the separation degree of semaglutide related impurities and a main peak is obviously improved, the impurity detection quantity is obviously increased, the method has more excellent peak appearance and column efficiency, and the product quality of semaglutide can be better monitored.

Owner:浙江湃肽生物股份有限公司南京分公司

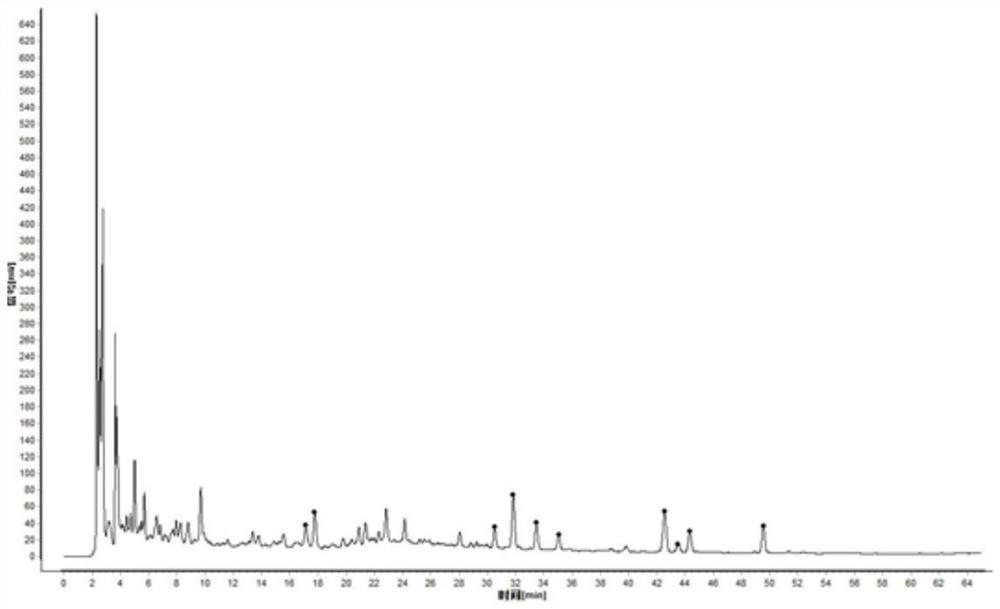

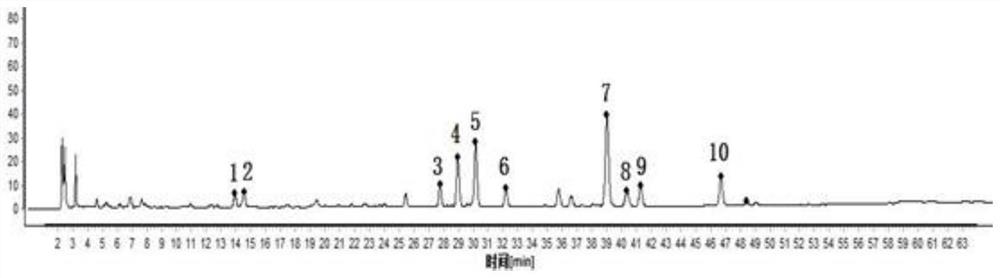

Establishment method of lindley eupatorium herb formula granule fingerprint as well as standard fingerprint and application thereof

ActiveCN114216978AFully reflect the quality statusFully extractedComponent separationMedicinal herbsPhysical chemistry

The invention provides a construction method of a lindley eupatorium herb formula granule fingerprint spectrum, a standard fingerprint spectrum of the lindley eupatorium herb formula granule and application of the standard fingerprint spectrum, and belongs to the technical field of medicine detection.The construction method comprises the steps that a test solution, a reference medicinal material solution and a reference substance solution are prepared, acetonitrile (A) and a 0.1-0.3 wt% phosphoric acid aqueous solution (B) are jointly used as mobile phases, and the standard fingerprint spectrum of the lindley eupatorium herb formula granule is obtained. Performing high performance liquid chromatography detection to obtain a fingerprint spectrum of the lindley eupatorium herb formula granules; the standard fingerprint spectrum of the lindley eupatorium herb formula granules is obtained by using the construction method, and the standard fingerprint spectrum is used for quality evaluation or control in the whole process of research / development / production / clinical application of the lindley eupatorium herb formula granules. According to the method for constructing the fingerprint spectrum of the lindley eupatorium herb formula granules, main medicinal material components in the lindley eupatorium herb formula granules can be detected only through high performance liquid chromatography, and the quality condition of the lindley eupatorium herb formula granules can be comprehensively reflected.

Owner:SHINEWAY PHARMA GRP LTD +2

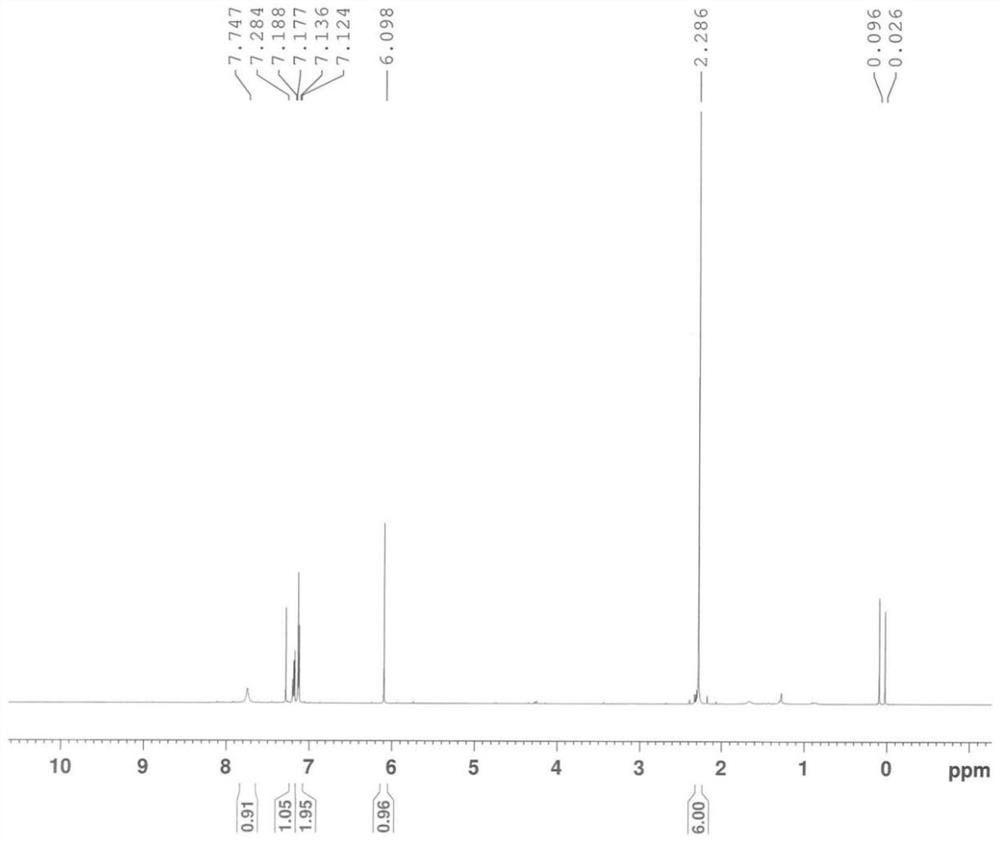

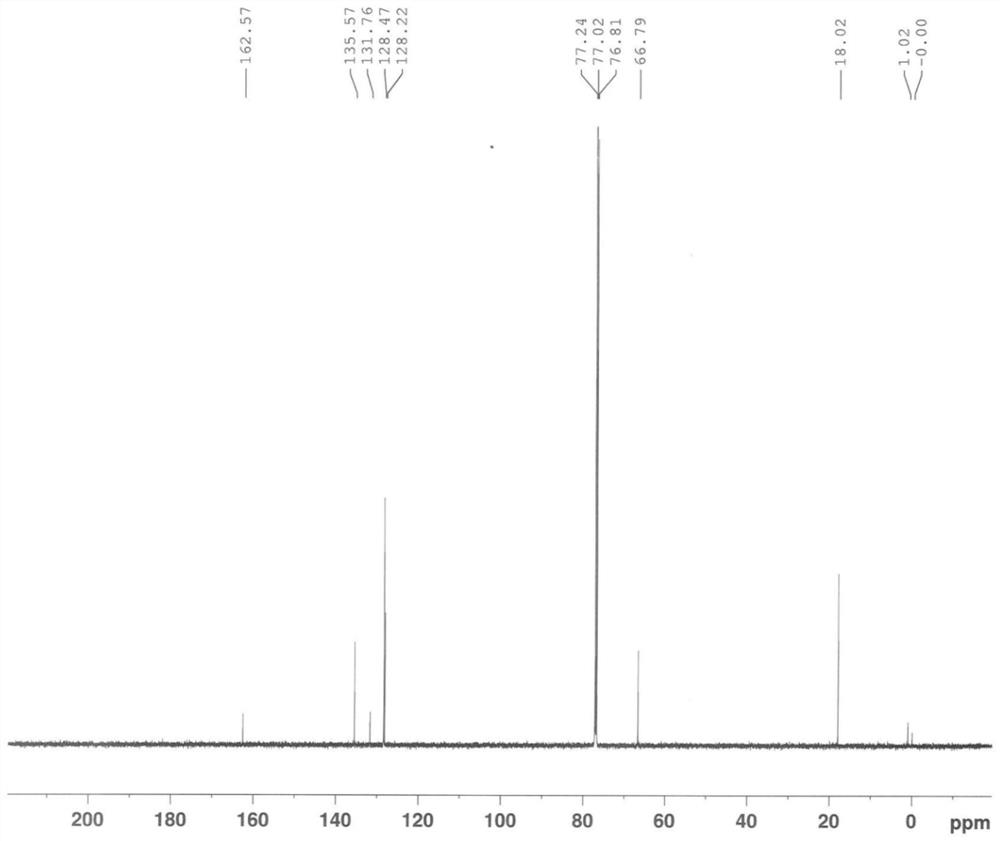

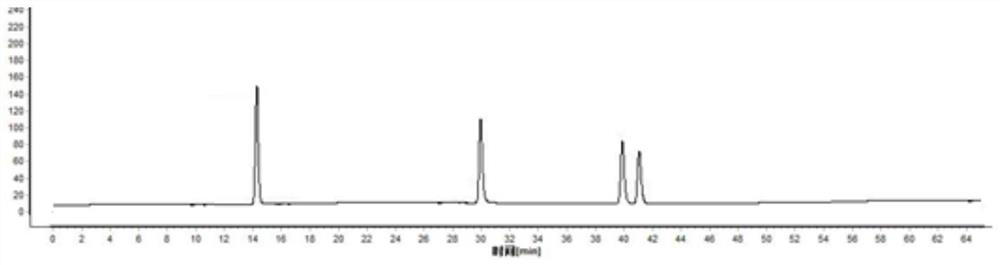

boc-(r)-3-amino-4-(2,4,5-trifluorophenyl)butanoic acid condensation impurity and preparation method thereof

ActiveCN109824546BSimple and fast operationModerate reaction conditionsCarbamic acid derivatives preparationOrganic compound preparationButyratePhosphoric acid

The invention provides an important intermediate of sitagliptin phosphate, BOC-(R)-3-amino-4-(2,4,5-trifluorophenyl)butyric acid condensation impurity, a preparation method and application thereof. The invention provides BOC-(R)-3-amino-4-(2,4,5-trifluorophenyl)butyric acid condensation impurities and a preparation method thereof, which is of great significance to the industrial production of subsequent raw materials.

Owner:ZHEJIANG YONGTAI TECH CO LTD +1

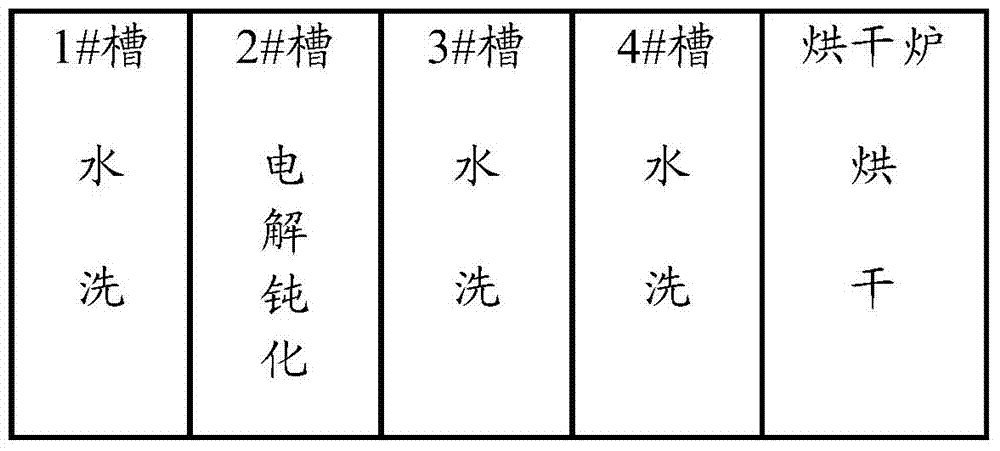

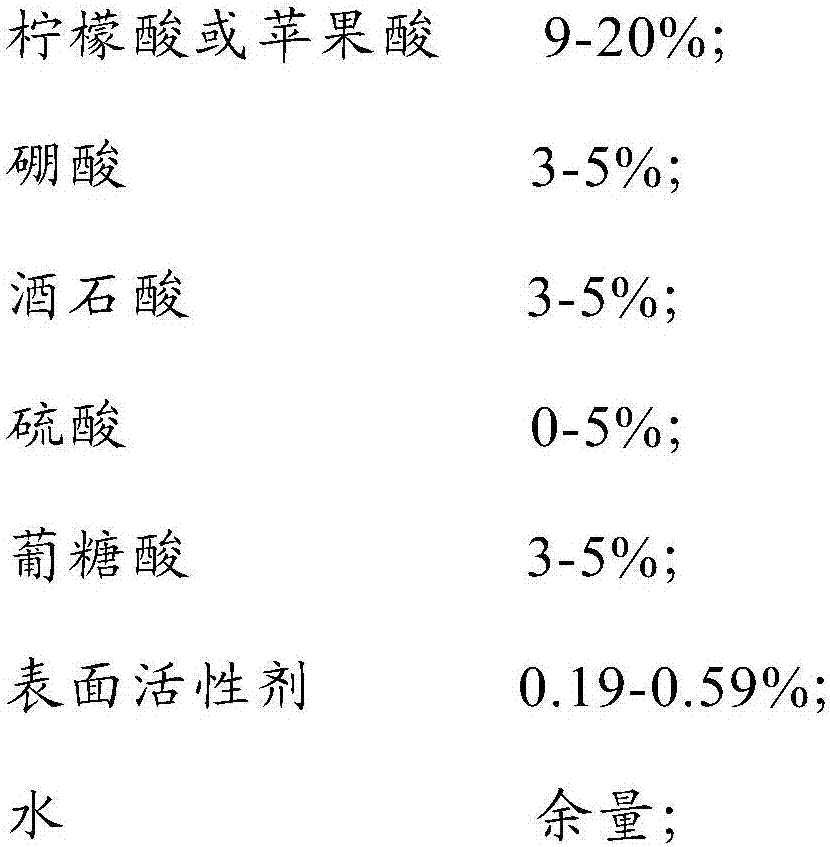

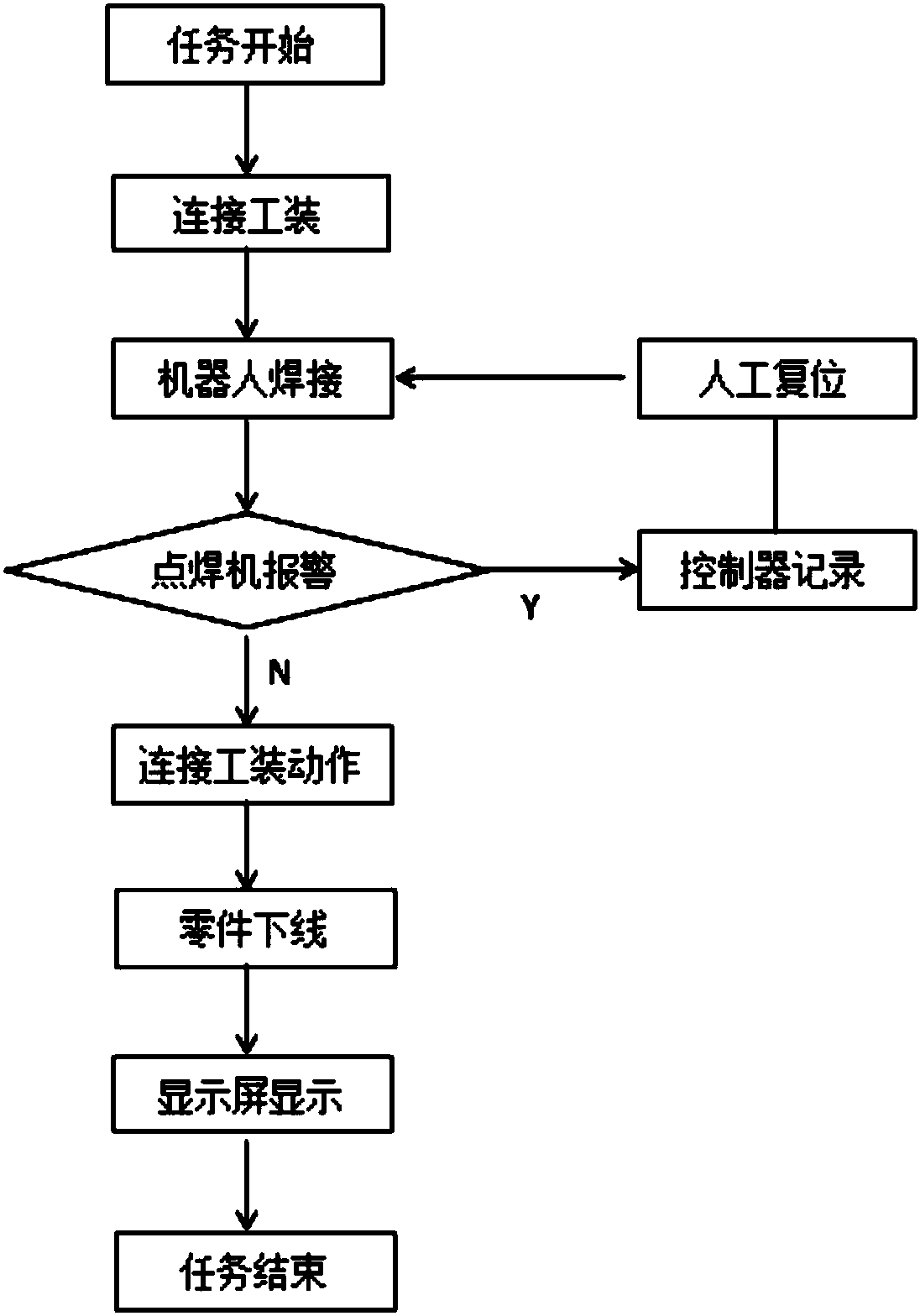

A kind of passivator and aluminum alloy pretreatment process

InactiveCN104195614BAvoid new pollutionConserve waterSurface reaction electrolytic coatingElectrolysisBoric acid

The invention provides a passivator and an aluminum alloy pre-treatment technology. The passivator consists of the following ingredients: 9-20% of citric acid or malic acid, 3-5% of boric acid, 3-5% of tartaric acid, 0-5% of sulfuric acid, 3-5% of glyconic acid, 0.19-0.59% of a surfactant and the balance of water. The aluminum alloy pre-treatment technology comprises the steps of water washing, electrolysis passivating, water washing, water washing and drying. A complex gelatinous passivating film layer is formed on the surface of an aluminum matrix by the aluminum alloy pre-treatment technology through electrolytic oxidation reaction.

Owner:南通市滨海装饰材料有限公司

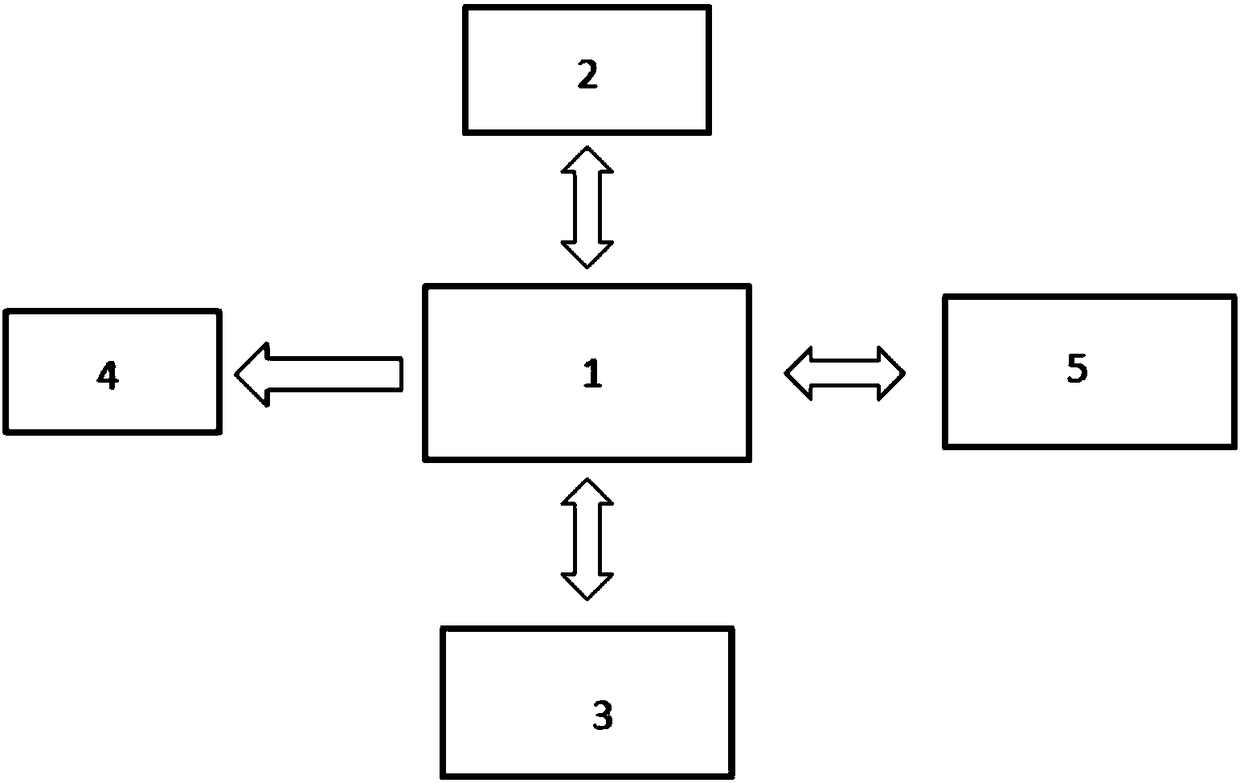

A robot connection process quality automatic control system and control method

ActiveCN105843184BReduce the frequency of detectionImprove efficiencyTotal factory controlProgramme total factory controlProcess qualityAutomatic control

Owner:SHANGHAI TRACTOR & INTERNAL COMBUSTION ENGINE

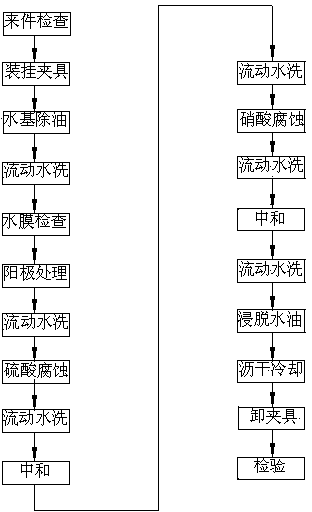

Chemical method for checking defects on processed carburized surface of steel part

ActiveCN102901708BEfficient removalClearly display defect areasPreparing sample for investigationColor/spectral properties measurementsWater basedPre treatment

The invention belongs to the field of checking of defects on processed carburized surface of a steel part and particularly relates to a chemical method for checking the defects on the processed carburized surface of the steel part. The chemical method comprises specific operation steps of performing pre-processing, first performing water-base oil removal, performing alkaline anodic treatment and sulfuric acid anodic corrosion to remove oxides on the surface and obtain clean surface and then performing nitric acid corrosion, wherein the carburized surface is gray after the nitric acid corrosion, the positions where the defects exist presents different colors and shapes, and accordingly the defects including softening, rehardening, carbonized soft spots, decarburization, grinding traces or scratch, crack, corrosion and the like of a carburizing layer in the carburizing and grinding process are displayed clearly. By means of the chemical method, the surfaces of the parts with the carburizing layers and parts without the carburizing layers can be placed into a tank simultaneously, the positions where the carburizing layers do not exist do not need insulating protection, the defects of the carburizing layers can be ensured to be displayed, and over corrosion are caused at other positions. In addition, macroscopic checking can be directly performed to parts, and the product quality can be effectively monitored.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com