Production monitoring method and device

A production line and production process technology, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as delays in handling abnormal production conditions, and achieve the effects of alleviating delays in processing and ensuring production quality and operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

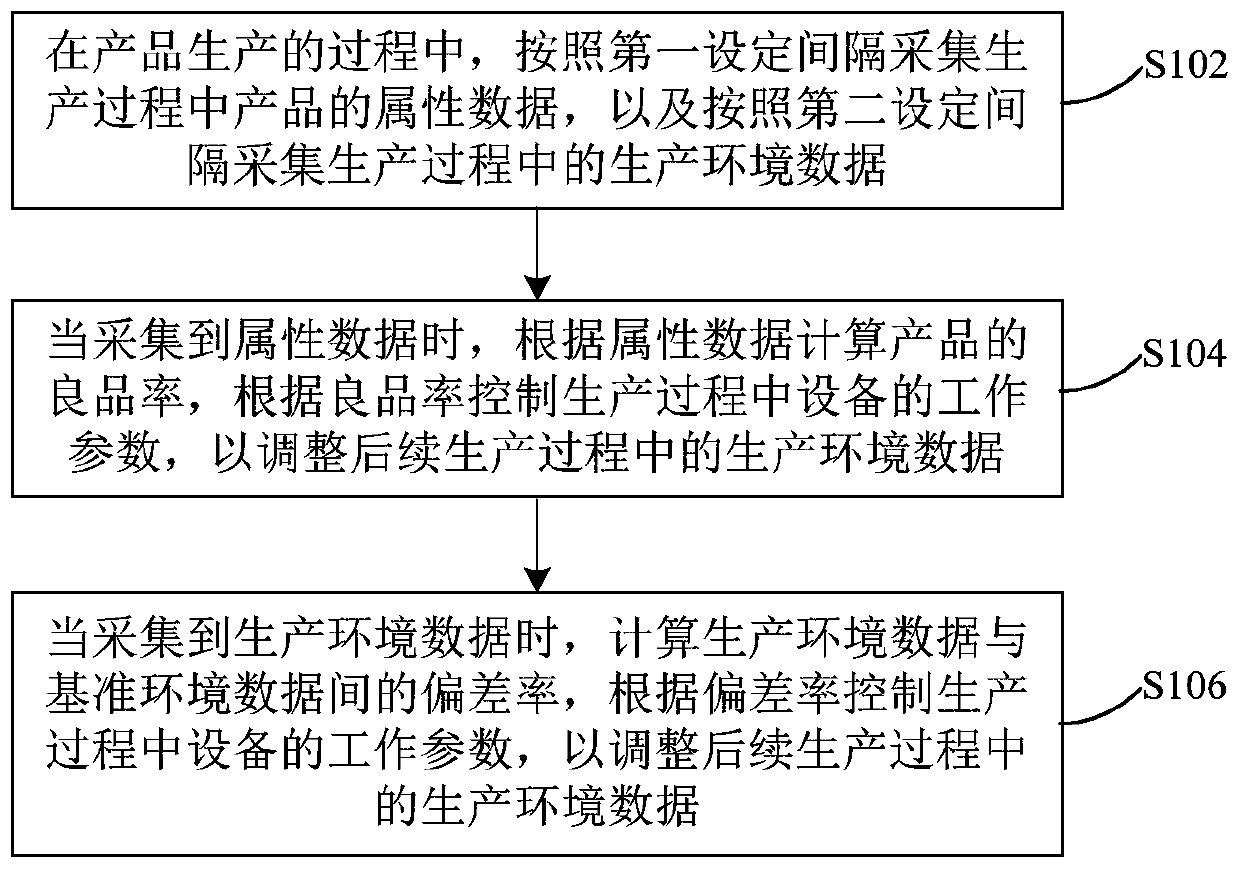

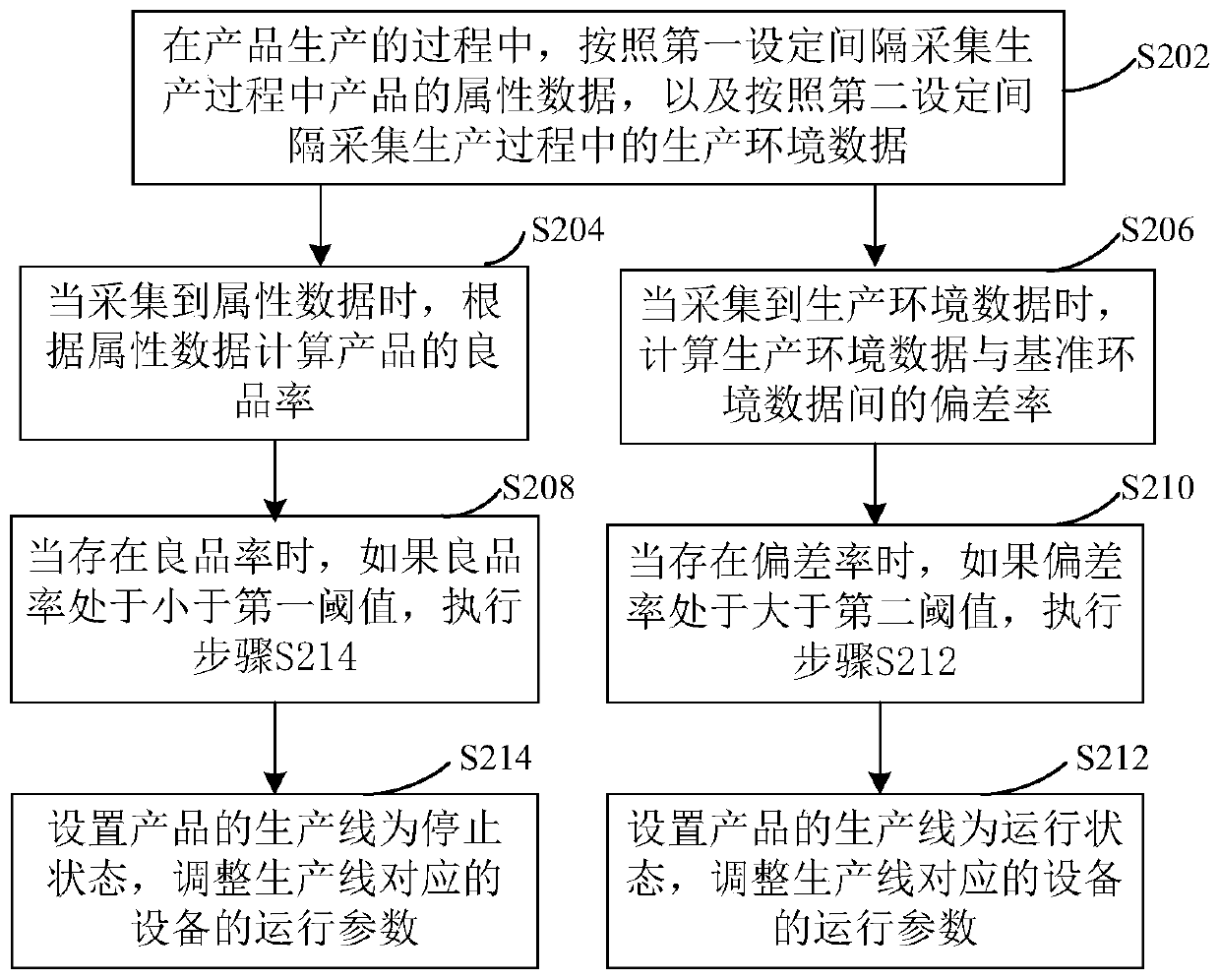

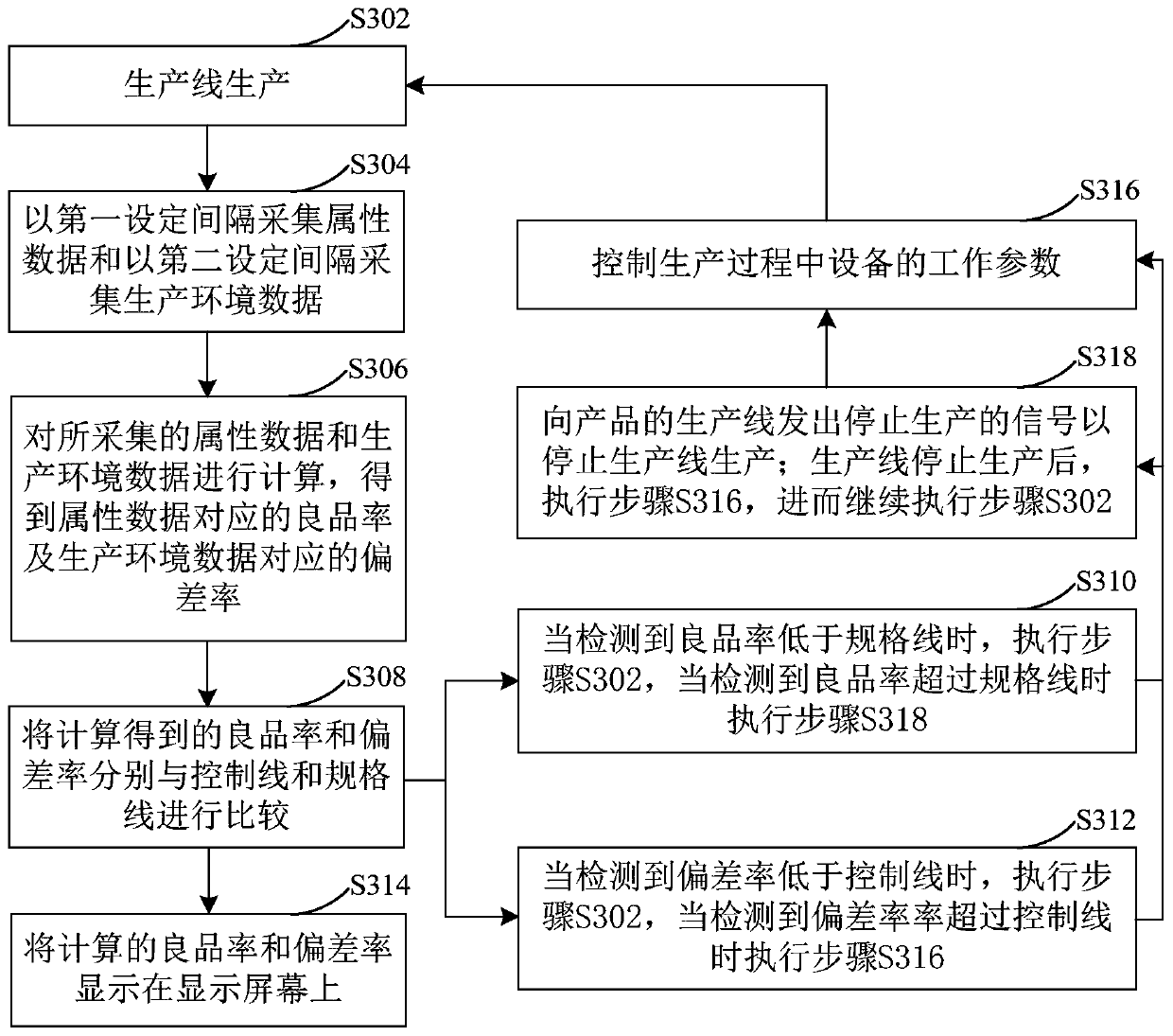

[0027] This embodiment provides a production monitoring method, refer to figure 1 A flow chart of a production monitoring method is shown, the method is applied to a controller, and the method includes the following steps:

[0028] Step S102, during the production process of the product, collect the attribute data of the product in the production process according to the first set interval, and collect the production environment data in the production process according to the second set interval;

[0029] In a specific implementation, the attribute data includes the quantity of good products and the quantity of defective products; since the attribute data is discrete data, the first setting interval can be set as a time period, such as an hour-level time period, such as one hour or two hours etc.; in the process of collecting the attribute data in the production process, what can be collected is the attribute data within the time period of the first set interval time. The att...

Embodiment 2

[0071] On the basis of the production monitoring method described in the above embodiments, the embodiment of the present invention also provides a production monitoring device, refer to Figure 4 A structural schematic diagram of a production monitoring device is shown, the device is applied to the controller, and the device includes the following modules:

[0072] The collection module 402 is used to collect the attribute data of the product in the production process according to the first set interval during the production process of the product, and collect the production environment data in the production process according to the second set interval; wherein, the attribute data includes good products Quantity and number of rejects;

[0073] Based on the yield rate control module 404, it is used to calculate the yield rate of the product according to the attribute data when the attribute data is collected, and control the working parameters of the equipment in the producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com