A kind of passivator and aluminum alloy pretreatment process

A passivation agent, aluminum alloy technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc. Increase fluorine pollution and other problems, to achieve the effect of shortening processing time, using less grooves, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

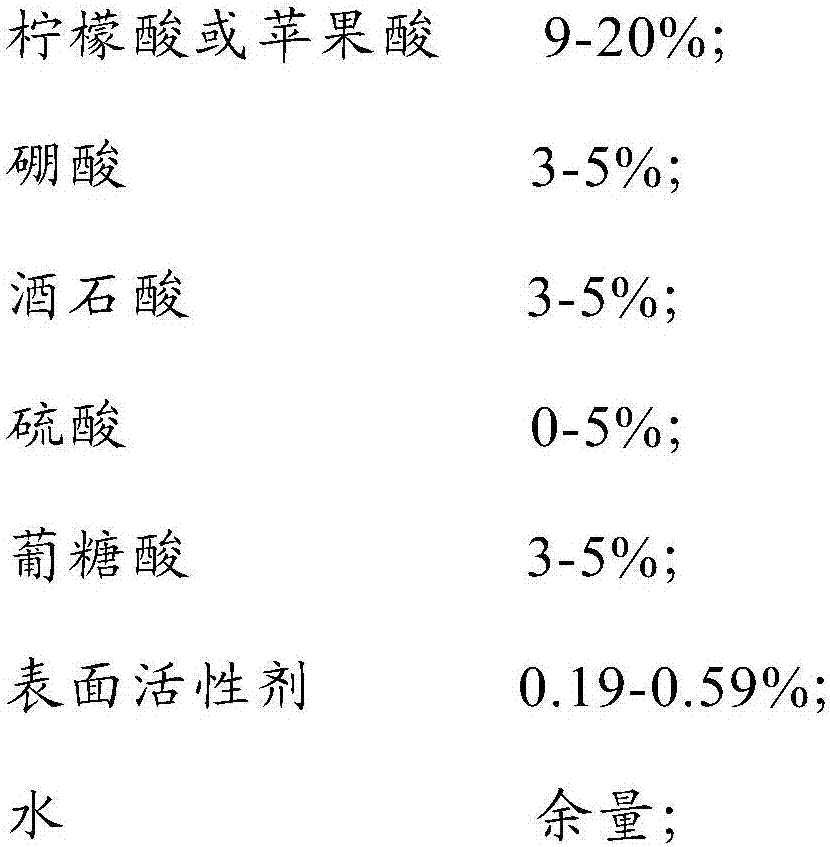

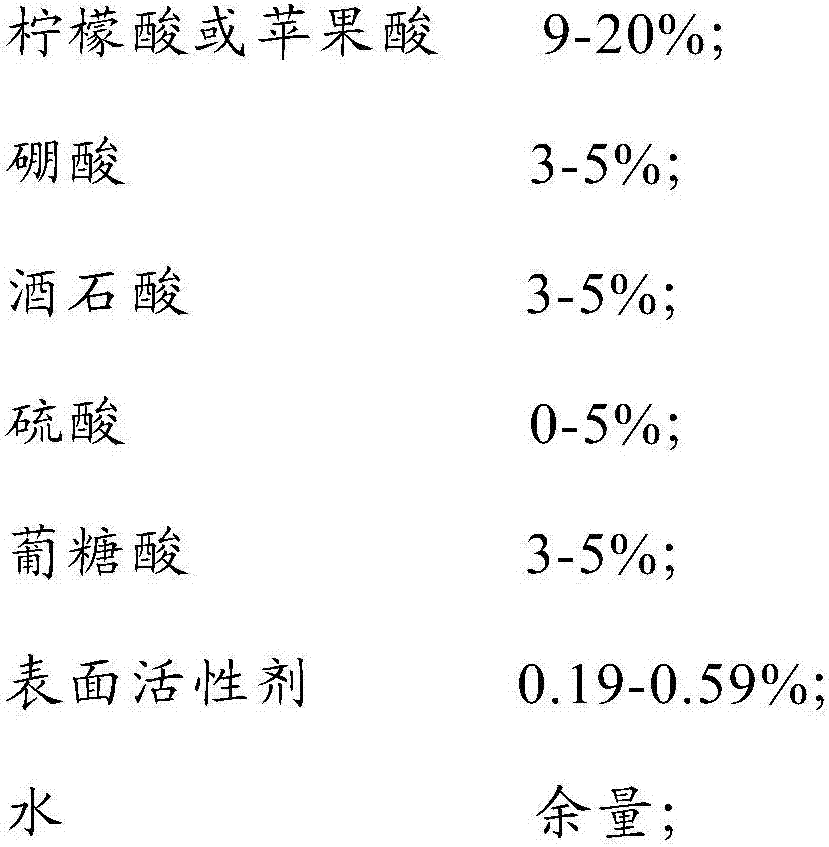

[0029] Example 1 Preparation of passivating agent

[0030] The passivation agent is prepared by injecting the required components into the reaction kettle in proportions and then stirring. In this example, the passivation agent required for preparation is prepared according to the weight percentage of each component in Table 1 plus water.

[0031] Table 1 The content of each component in the passivator

[0032]

[0033]

Embodiment 2

[0034] In Example 2, the same steps were performed with formula A, a, F, f, K, k, P, and p respectively

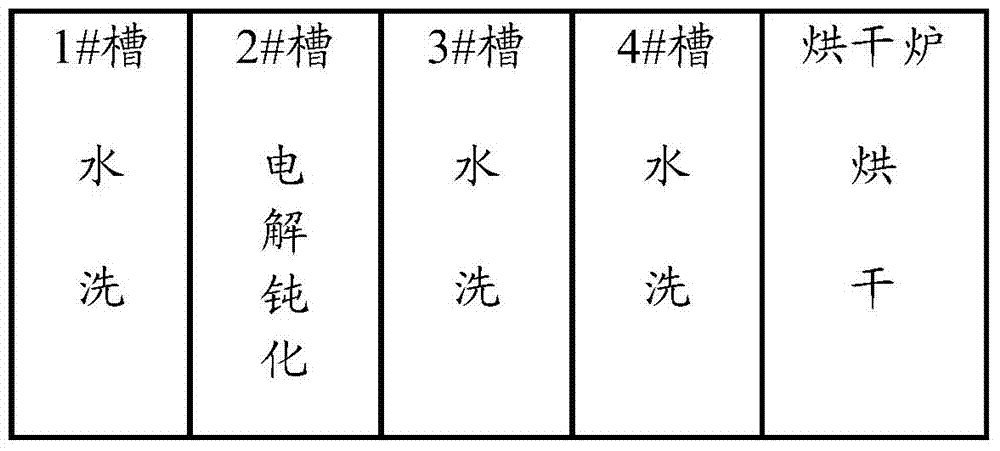

[0035] The aluminum profile enters the 1# tank, washes up and down for 2 minutes at room temperature, and hangs out dripping for 1.0min; enters the 2# tank, after the power is turned on, the temperature rises and stabilizes to 36℃~38℃, the passivation agent content 58g / L (1 liter of water The passivation agent content is 58 grams), DC voltage is set to 15V, current density is set to 0.15A / dm 2 , Time 4min, hanging out dripping 1.0min; entering 3# tank, room temperature, washing up and down for 2min, hanging out dripping 1.0min; entering 4# tank, room temperature, washing up and down for 2min, hanging out dripping 1.0min; into drying Furnace, the temperature is set at 60℃, and the oven is baked for 20 minutes;

[0036] The thickness of the gel-like passivation film formed on the pre-treatment surface is 0.3-0.4 microns, and the product quality is stable. The aluminum profile tre...

Embodiment 3

[0037] In Example 3, the same steps were performed with formula B, b, G, g, L, 1, Q, and q respectively

[0038] The aluminum profile enters the 1# tank, washes at room temperature for 2 minutes up and down, and hangs out dripping for 0.5min; enters the 2# tank, after electrifying, the temperature is stable at 8℃~10℃, the passivating agent content is 60g / L, and the DC voltage is set to 18V , Current density setting 0.13A / dm 2 , Time 6min, hanging out dripping 0.5min; entering 3# tank, room temperature, washing up and down for 2min, hanging out dripping 1.0min; entering 4# tank, room temperature, washing up and down for 2min, hanging out dripping 1.0min; into drying Furnace, set the temperature to 80℃, and bake for 25min.

[0039] The thickness of the gel-like passivation film formed on the surface of the aluminum profile is 0.3-0.4 microns, and the product quality is stable. The aluminum profile treated in this way can be used for further spraying flat powder. After spraying treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com