Chemical method for checking defects on processed carburized surface of steel part

A surface processing and chemical method technology, applied in the preparation of test samples, color/spectral characteristic measurement, etc., can solve the problems of long operation cycle and inability to inspect defects macroscopically, and achieve the effect of effective product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

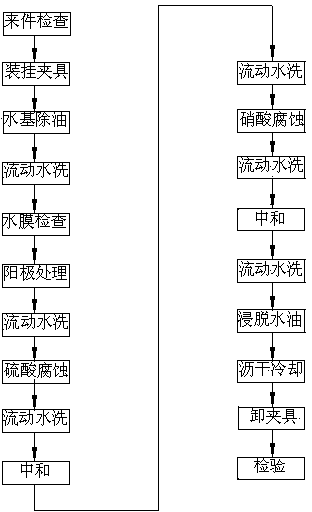

Method used

Image

Examples

Embodiment 1

[0026] For an inner bearing ring part, the bearing ring part has a carburized surface, and the rest of the surface has no carburized layer. The present invention is used to perform a macroscopic inspection of the carburized surface processing defects according to the following steps:

[0027] (1) Water-based oil removal: Use Turco4215 with a concentration of 36 g / L to remove oil, the dosage is 28.8 kg, and the solution temperature is 55 °C;

[0028] (2) When performing the water washing process, wash with running water at room temperature for 10 seconds, turn on the spray device, and rinse the parts with a water gun to remove residual solution traces, and the parts will not appear rusted;

[0029] (3) Water film inspection: Drain for 5s to check the water film, the water film inspection time is 20s, and the water film is continuous;

[0030] (4) Anode cleaning: parts are used as anodes, and the tank body is used as cathodes. The solution composition is 52kg of sodium hydroxide...

Embodiment 2

[0038] For a low-pressure short shaft part, the bearing ring part has a carburized surface, and the rest of the surface has no carburized layer. The present invention is used to perform a macroscopic inspection of the carburized surface processing defects according to the following steps:

[0039] (1) Water-based oil removal: Use Turco4215 with a concentration of 42g / L to remove oil, the dosage is 42kg, and the solution temperature is 60°C;

[0040] (2) During the water washing process, wash with running water at room temperature for 20 seconds, turn on the spray device, and rinse the parts with a water gun to remove residual solution traces, and the parts will not appear rusted;

[0041] (3) Water film inspection: Drain for 10s to check the water film, the water film inspection time is 25s, and the water film is continuous;

[0042] (4) Anode cleaning: parts are used as anodes, and the tank body is used as cathodes. The solution composition is 80kg of sodium hydroxide solutio...

Embodiment 3

[0050] The front short shaft part of a certain compressor has a carburized surface on the bearing ring, and no carburized layer on the rest of the surface. The present invention is used to perform a macroscopic inspection on the processing defects of the carburized surface according to the following steps:

[0051] (1) Water-based oil removal: Use Turco4215 with a concentration of 48g / L to remove oil, the dosage is 57.6kg, and the solution temperature is 50°C;

[0052] (2) During the water washing process, wash with running water for 30s at room temperature, turn on the spray device, and rinse the parts with a water gun to remove residual solution traces, and the parts will not appear rusty;

[0053] (3) Water film inspection: Drain for 20s to check the water film, the water film inspection time is 30s, and the water film is continuous;

[0054] (4) Anode cleaning: the part is used as the anode, and the tank is used as the cathode. The solution composition is 110.4kg of sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com