A robot connection process quality automatic control system and control method

A robot and quality technology, applied in the direction of general control system, control/regulation system, comprehensive factory control, etc., can solve the problems of human resources waste, product waste, quality problem discovery and control unsatisfactory, etc., to reduce waste, The effect of improving personnel efficiency and reducing the frequency of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described now in conjunction with accompanying drawing.

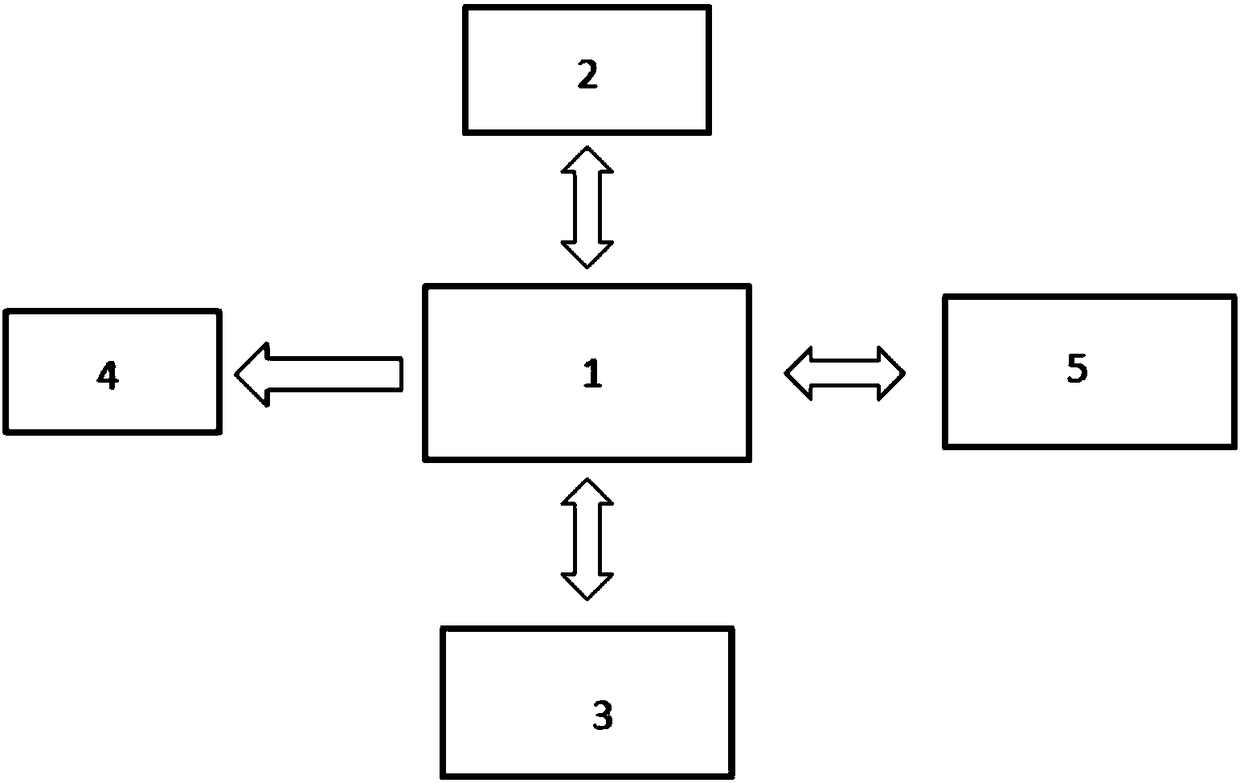

[0014] see figure 1 , the present invention is an automatic control system for robot connection process quality, comprising a controller, a spot welder, a connection robot, a display screen and a connection tooling, characterized in that: the first field bus port of the controller 1 and the connection of the spot welder 2 Field bus port connection, the second field bus port of the controller 1 is connected to the field bus port connected to the robot 3, the third field bus port of the controller 1 is connected to the field bus port connected to the tooling 5, and the physical address port of the controller 1 Connect with the physical address port of display screen 4. Among them, the spot welding machine 2 can be replaced by an FDS machine or an SPR machine, and each component connected to the controller 1 can receive a control signal from the controller to make it move, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com