Base board detector and glass base board detector

A substrate inspection and inspection equipment technology, applied in semiconductor/solid-state device testing/measurement, measurement devices, optical testing flaws/defects, etc., can solve problems such as increasing the time and equipment cost of transporting glass substrates, and being unable to monitor and control production quality in real time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The invention provides a detection device applicable to various substrates. However, in a preferred embodiment, the present invention is mainly applicable to the inspection of glass substrates, especially the inspection of glass substrates processed by color filters (Color Filter, CF). The invention has the advantages of online real-time detection and monitoring of the pass rate of the substrate and mass production. The above-mentioned color filter is mainly used in flat-panel displays such as TFT-LCD, PDP or EL. However, in different embodiments, the substrate can also be applied in semiconductor, chemical industry, traditional industry or other different fields. Below promptly coordinate accompanying drawing, further illustrate each specific embodiment of the present invention and steps thereof:

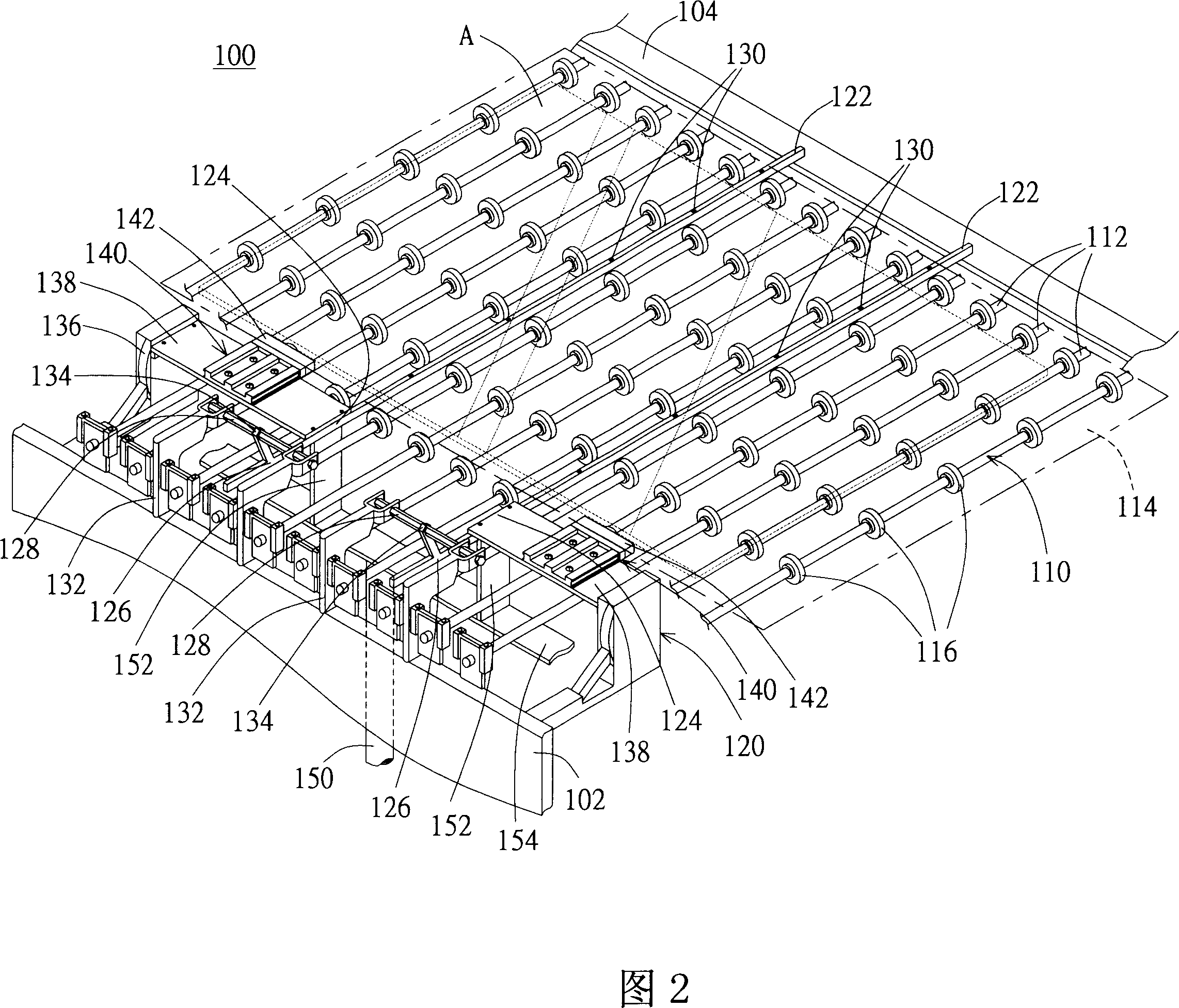

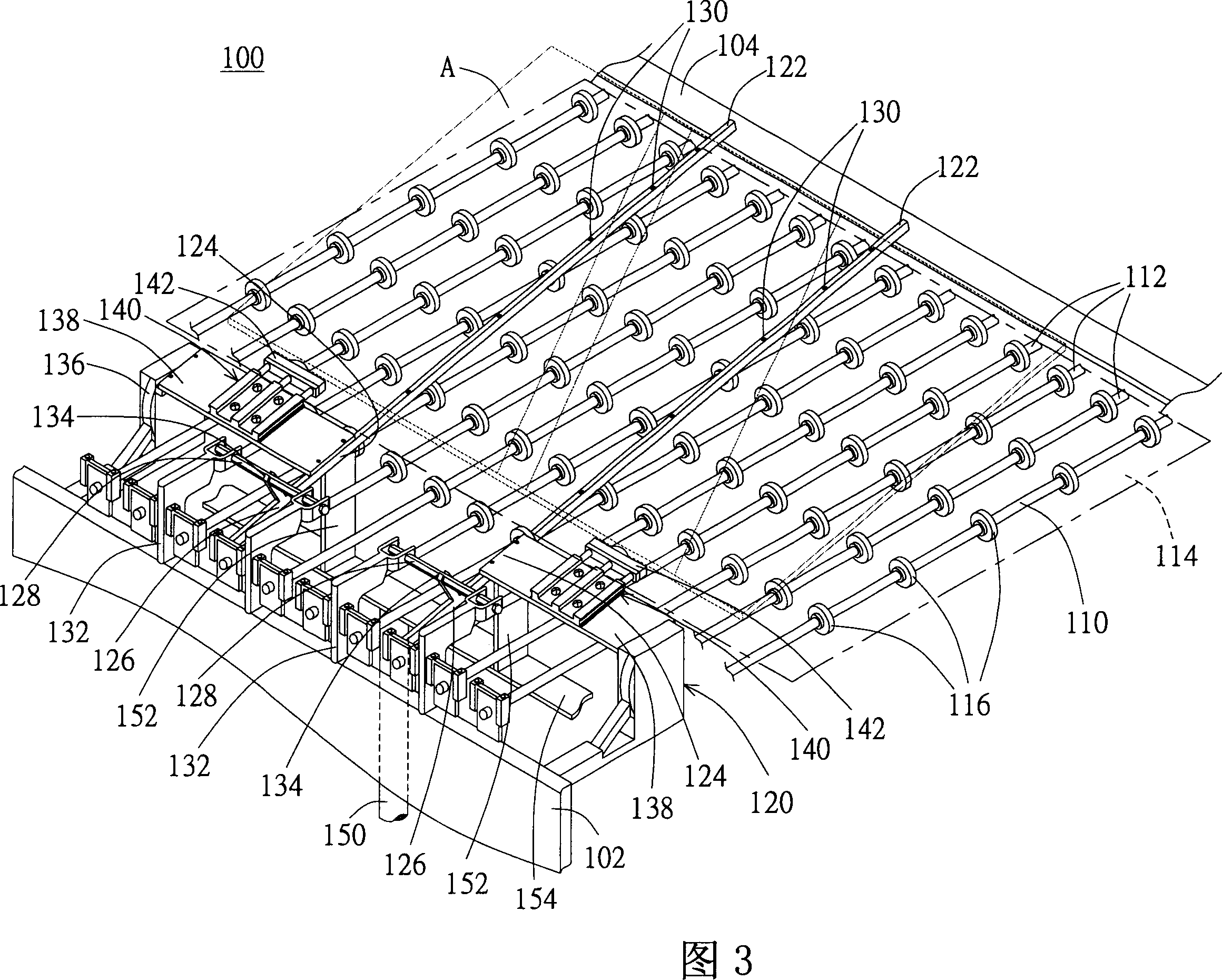

[0035] Fig. 2 and Fig. 3 are schematic diagrams of embodiments of the lifting mechanism of the present invention. The substrate inspection apparatus 100 of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com