Preparation method of dynamically-vulcanized ethylene propylene diene monomer rubber waterproof coiled material

A technology of vulcanizing ternary and ethylene-propylene rubber, which is applied in the direction of flat products, other household appliances, household appliances, etc., can solve the problems of the continuous production process of waterproof membrane, poor stability of waterproof membrane and unstable product quality, etc. , to achieve the effect of improved physical and chemical properties, excellent corrosion resistance, simple and continuous process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Add rubber, plastics, fillers, and processing aids in proportion to the first twin-screw extruder through a weight loss scale, and plasticize, shear, knead, and extrude into a mixing strip, and the first twin-screw barrel The temperature is controlled at 200°C to ensure that the components are mixed evenly;

[0024] (2) Add the mixed strip processed and extruded by the first twin-screw extruder into the second twin-screw extruder, and add vulcanization system and other processing aids in proportion, through melting, mixing, exhausting, Metering, complete the dynamic vulcanization reaction, and extrude the semi-finished sheet, the temperature of the second twin-screw barrel is controlled at 170-250°C, and the screw speed is 100r / min;

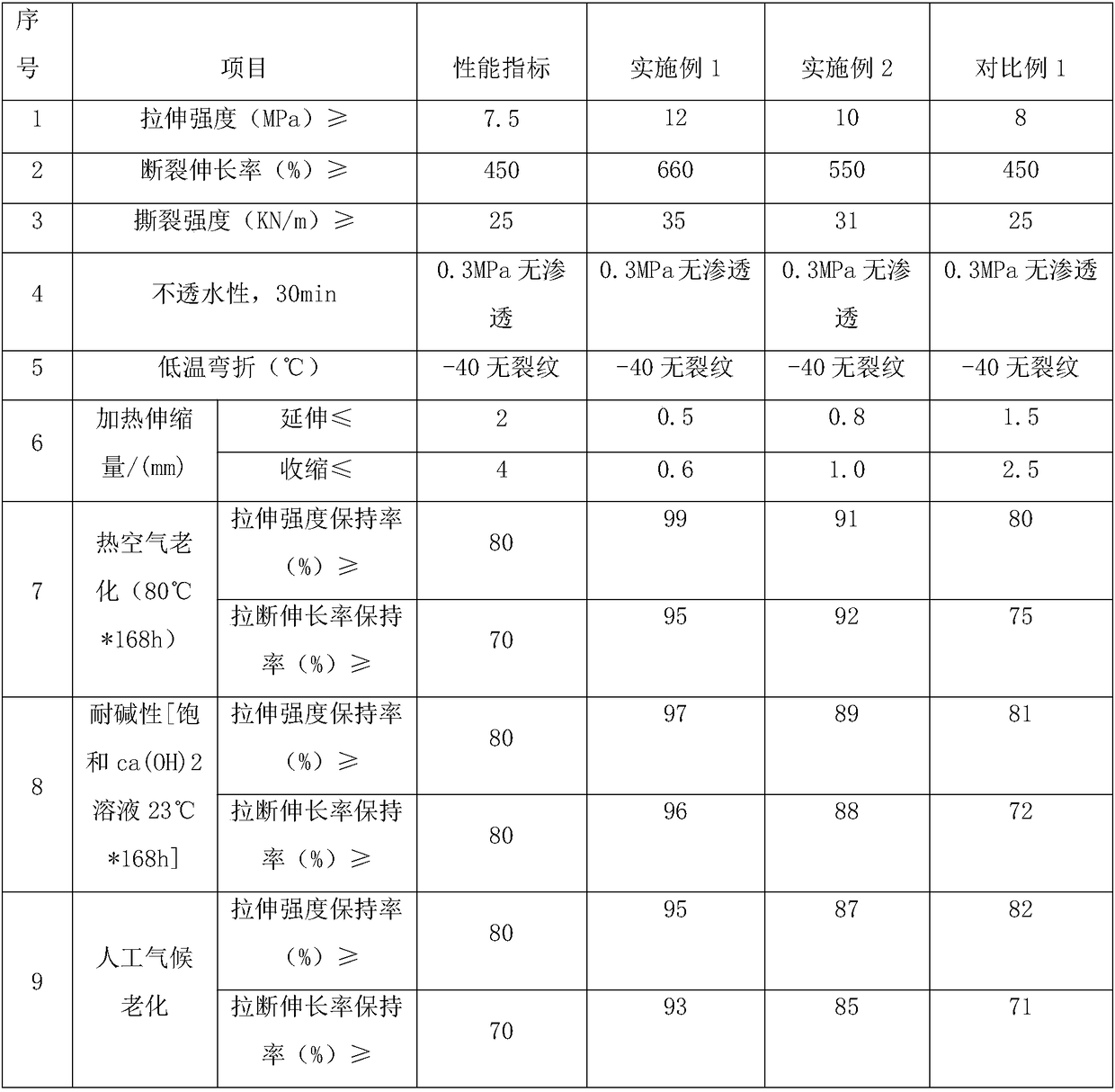

[0025] (3) The sheet extruded by the second twin-screw extruder is shaped by a three-roll calendering system, and finally cooled and stored to prepare the finished dynamic vulcanized EPDM waterproof membrane. The prepared dynamic vulca...

Embodiment 2

[0027] (1) Add rubber, plastics, fillers, and processing aids in proportion to the first twin-screw extruder through a weight loss scale, and plasticize, shear, knead, and extrude into a mixing strip, and the first twin-screw barrel The temperature is controlled at 170°C to ensure that the components are mixed evenly;

[0028] (2) Join the second twin-screw extruder after pelletizing the mixing strip extruded by the first twin-screw extruder, and add vulcanization system and other processing aids in proportion, through melting, mixing, Exhaust and measure, complete the dynamic vulcanization reaction, and extrude the semi-finished sheet, the temperature of the second twin-screw barrel is controlled at 170°C, and the screw speed is 50r / min;

[0029] (3) The sheet extruded by the second twin-screw extruder is shaped by a twin-roller calendering system, and finally cooled and stored to prepare a dynamic vulcanized EPDM waterproof membrane product. The prepared dynamic vulcanized E...

Embodiment 3

[0031] (1) Add rubber, plastics, fillers, and processing aids in proportion to the first twin-screw extruder through a weight loss scale, and plasticize, shear, knead, and extrude into a mixing strip, and the first twin-screw barrel The temperature is controlled at 185°C to ensure that the components are mixed evenly;

[0032] (2) Add the mixed strip processed and extruded by the first twin-screw extruder into the second twin-screw extruder, and add vulcanization system and other processing aids in proportion, through melting, mixing, exhausting, Metering, complete the dynamic vulcanization reaction, and extrude the semi-finished sheet, the temperature of the second twin-screw barrel is controlled at 210°C, and the screw speed is 70r / min;

[0033] (3) The sheet extruded by the second twin-screw extruder is shaped by a five-roll calendering system, and finally cooled and stored to prepare the finished dynamic vulcanized EPDM waterproof membrane. The prepared dynamic vulcanized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com