Sheet molding compound, and composition, preparation and application thereof

A sheet molding compound and composition technology, applied in the field of electromagnetic shielding materials, can solve the problems of difficult mechanization, high cost, unfavorable practical application, etc., achieve high electromagnetic shielding efficiency, large electromagnetic wave loss, and prevent absorption saturation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

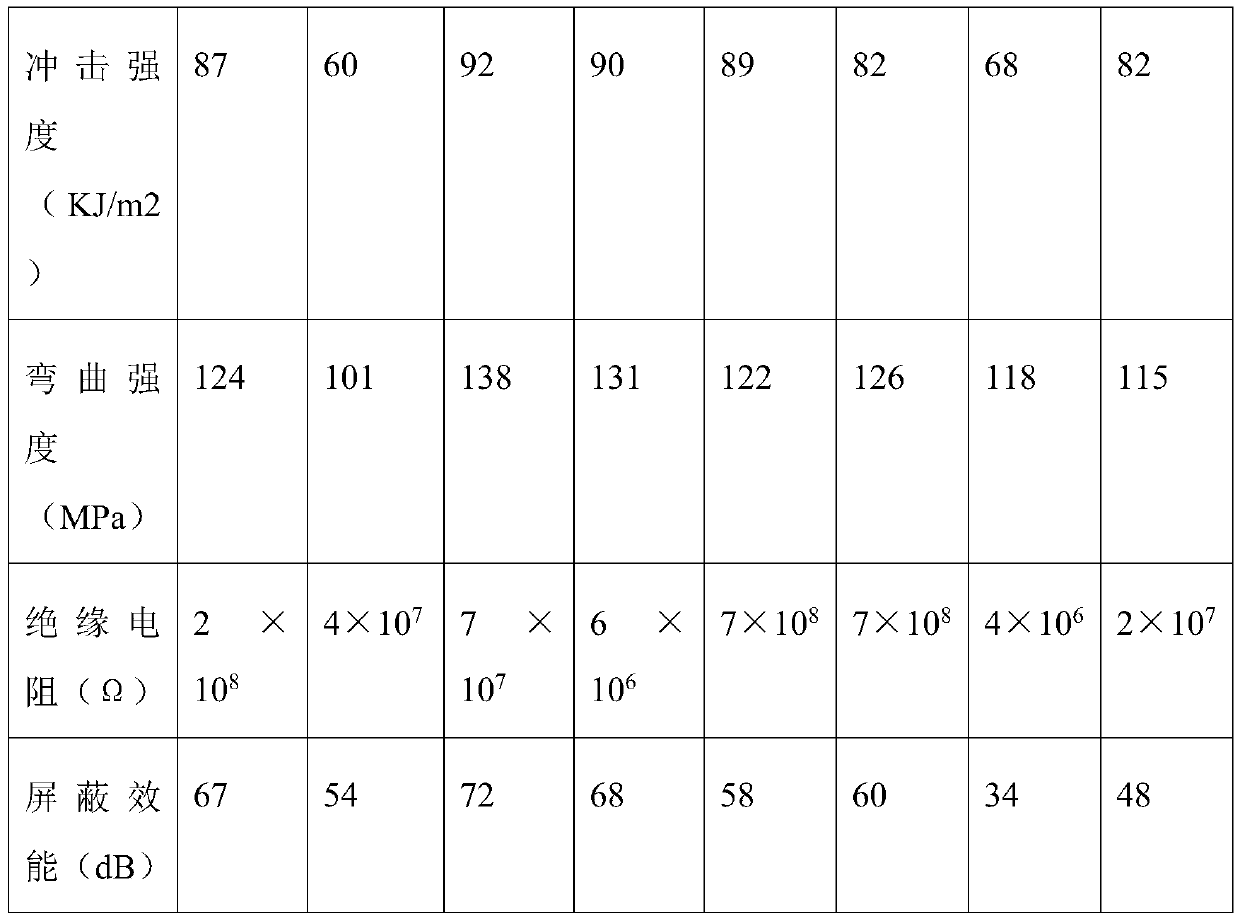

Embodiment 1

[0075] Composite SMC type electromagnetic shielding material is prepared through the following process:

[0076] (1) Prepare resin paste, including:

[0077] Prepare resin paste A:

[0078] In terms of parts by mass, 100 parts of 9508 isophthalic unsaturated polyester resin, 80 parts of aluminum hydroxide, 10 parts of tetraacicular zinc oxide whiskers with an average particle size of 200 μm, and iron-silicon aluminum alloy with an average particle size of 10 μm 40 parts of powder, 3 parts of mold release agent zinc stearate, 3 parts of thickener magnesium oxide, 1 part of curing agent (2-ethylhexyl) tert-butyl peroxide, 8 parts of low shrinkage agent polystyrene, anti Oxygen agent 2,5, 2 parts of di-tert-butylhydroquinone and 2 parts of KH550 silane coupling agent are mixed to form resin paste A;

[0079] Prepare resin paste B:

[0080] In parts by mass, 100 parts of 9508 isophthalic unsaturated polyester resin, 400 parts of carbonyl iron with an average particle diameter o...

Embodiment 2

[0091] Composite SMC type electromagnetic shielding material is prepared by the same process as in Example 1, wherein:

[0092] Resin paste A contains 100 parts of 9508 isophthalic unsaturated polyester resin, 90 parts of second filler, 3 parts of release agent zinc stearate, 3 parts of thickener magnesium oxide, curing agent (2-ethylhexyl) 1 part of tert-butyl peroxide, 10 parts of low shrinkage agent polystyrene, 0.5 part of anti-aging agent p-phenylenediamine and 2 parts of KH560 silane coupling agent;

[0093] Resin paste B contains 100 parts of 9508 isophthalic unsaturated polyester resin, 300 parts of first filler, 3 parts of release agent zinc stearate, 3 parts of thickener magnesium oxide, curing agent (2-ethylhexyl) 1 part of tert-butyl peroxide, 10 parts of low shrinkage agent polystyrene, 0.5 part of anti-aging agent p-phenylenediamine and 2 parts of KH560 silane coupling agent;

[0094] The fiber is 30 parts, cut into 20mm long, choose carbon fiber;

[0095] The ...

Embodiment 3

[0101] Composite SMC type electromagnetic shielding material is prepared by a process similar to Example 1, the difference is only that the SMC sheet after curing in step (3) is in the pressing process, and the surface layer is added with copper mesh for co-curing.

[0102] in:

[0103] Resin paste A contains 100 parts of 9508 isophthalic unsaturated polyester resin, 90 parts of second filler, 3 parts of release agent stearic acid, 4 parts of thickener magnesium oxide, curing agent (2-ethylhexyl) 1 part of tert-butyl oxide, 8 parts of low shrinkage agent polystyrene, 1 part of antioxidant diaryl secondary amine and 2 parts of KH550 silane coupling agent;

[0104] Resin paste B contains 100 parts of 9508 isophthalic unsaturated polyester resin, 320 parts of first filler, 3 parts of release agent stearic acid, 4 parts of thickener magnesium oxide, curing agent (2-ethylhexyl) 1 part of tert-butyl oxide, 8 parts of low shrinkage agent polystyrene, 1 part of antioxidant diaryl secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com