Detecting, bending and feeding device and method for two-device assembly

A visual inspection device and component technology, applied in sorting and other directions, can solve problems such as parts falling off, labor-intensive, abnormal assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

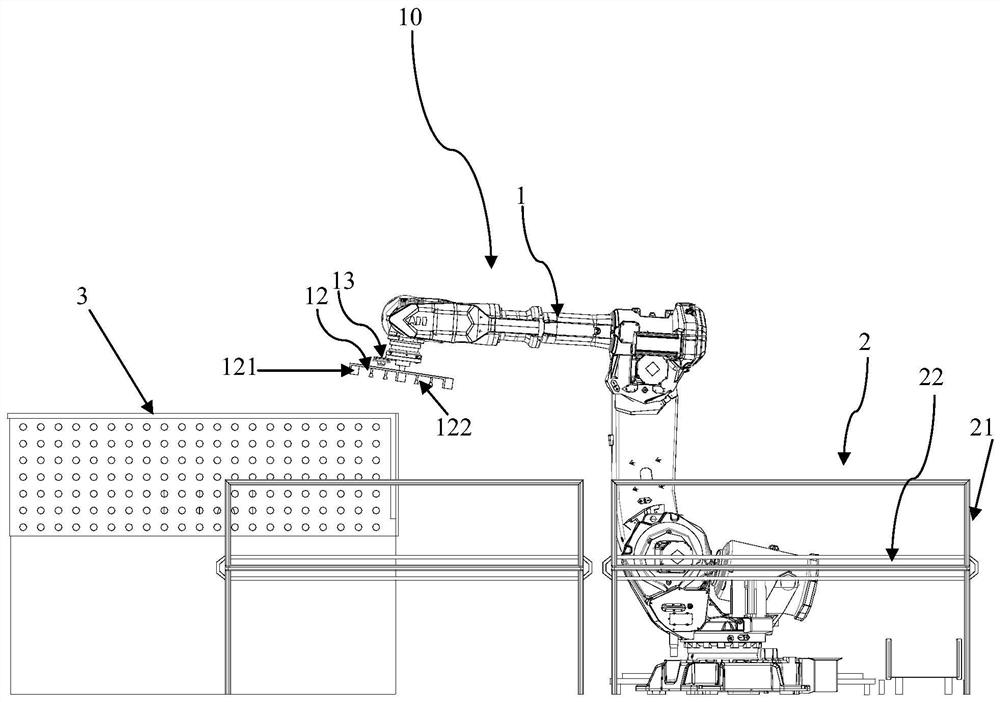

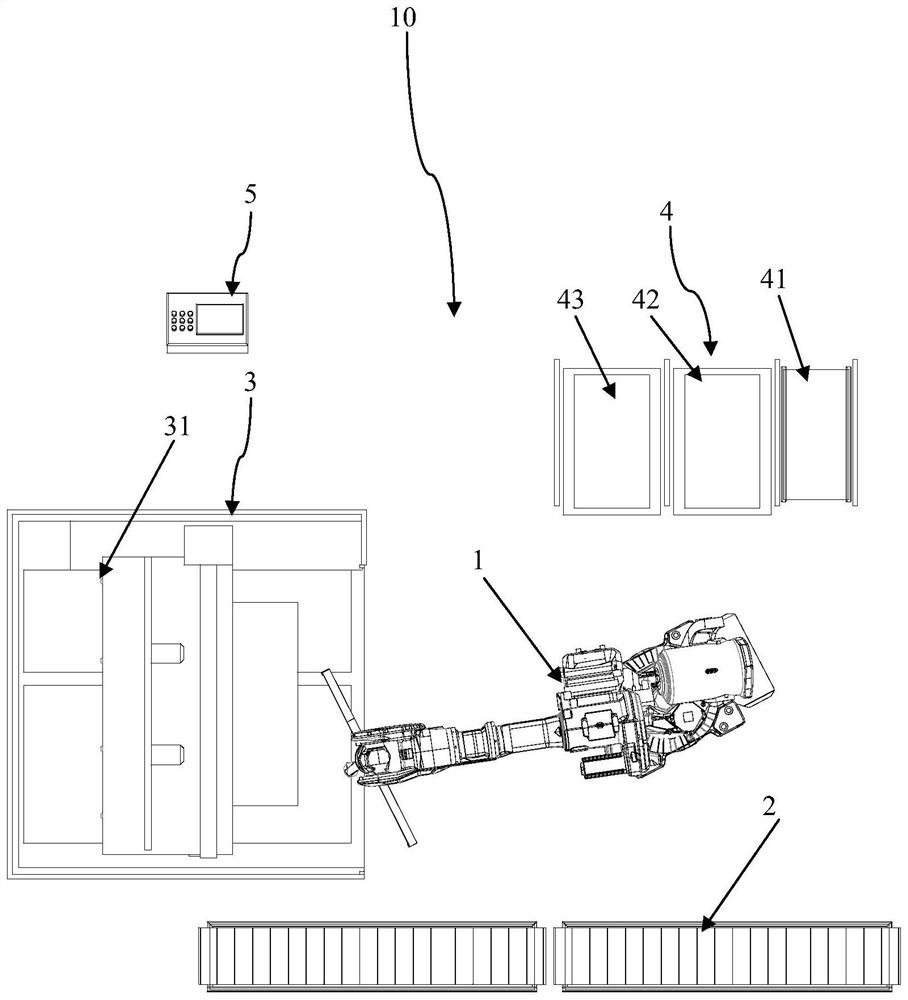

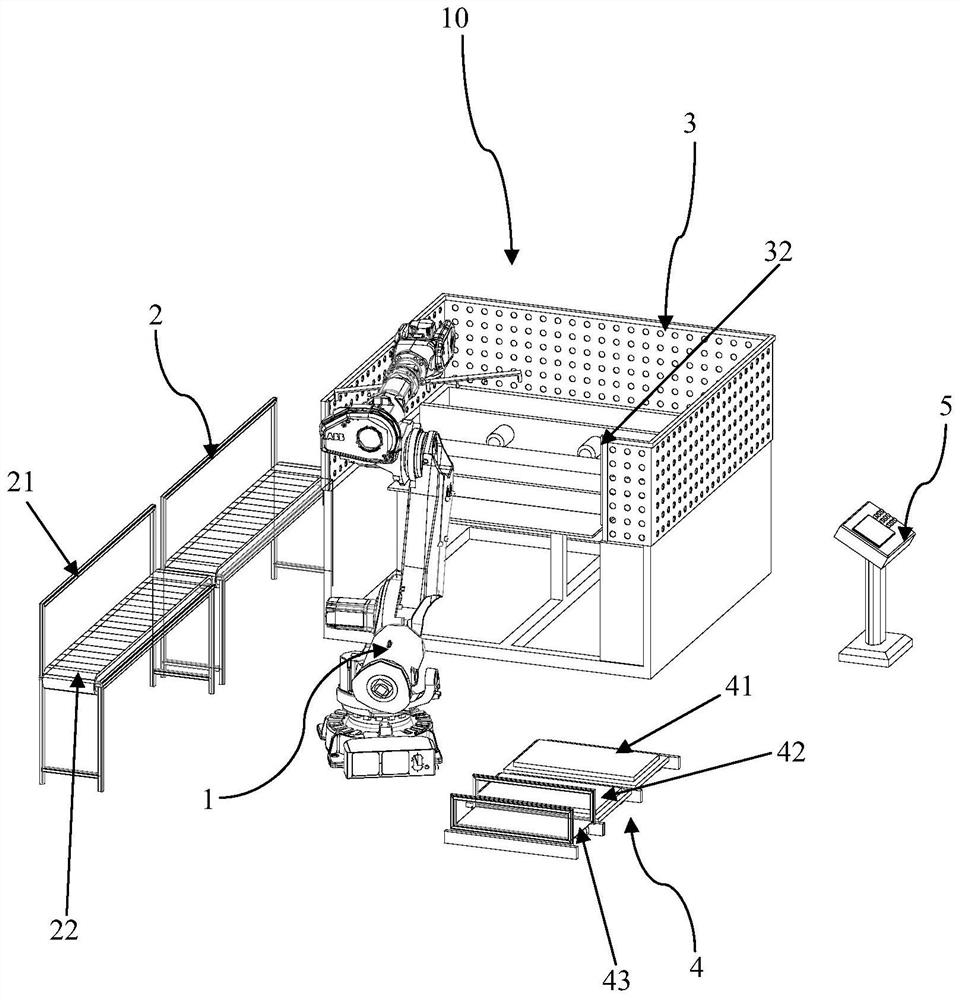

[0034] Such as Figure 1 to Figure 3 As shown, the detection, bending, and on-line device 10 for the two-device assembly according to the embodiment of the present invention includes a handling device 1 , a material delivery system 2 , a bending machine 3 , a material placement platform 4 and a console 5 . Wherein, the transport device 1 includes a robot 11 , and the robot 11 is provided with a grasping system 12 and a visual inspection device 13 . The console 5 is equipped with a preset program capable of controlling the robot 11. The console 5 can control the running track of the robot 11, the grabbing system 12 grabs and places materials, and controls the visual inspection device 13 to detect the size of the materials and control the material transmission. Startup and shutdown of system 2 and press brake 3.

[0035] According to the embodiment of the present invention, the detection, bending, and on-line device for the two-device assembly adopts the automatic detection of ...

Embodiment 2

[0041]According to the embodiment of the present invention, the method for detecting, bending, and launching the two-device assembly is implemented by the above-mentioned device 10, including the following steps: S01. Input the component material code on the console before starting the machine, and the device 10 will follow the preset method. Set the program action; S02, the robot 1 runs from the initial station to the top of the loading area 42, and the visual inspection device 13 detects whether the size of the two components in the loading area 42 is qualified. 121 Place the two-machine assembly in the unqualified product placement area 41; S03, the clamping device 121 clamps and detects the qualified two-machine assembly and places it in the working area of the bending machine 3, and the bending machine 3 performs bending; S04, Bending After the completion, the robot 1 runs to the designated area of the bending machine 3, and the clamping device 121 clamps and places th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com