Automatic production line and production manner of centrifugal cast pipes

A technology of automatic production line and centrifugal casting pipe, which is applied in foundry workshops, casting equipment, equipment for supplying molten metal, etc., and can solve problems such as waste of working hours, low production efficiency, and poor control of product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

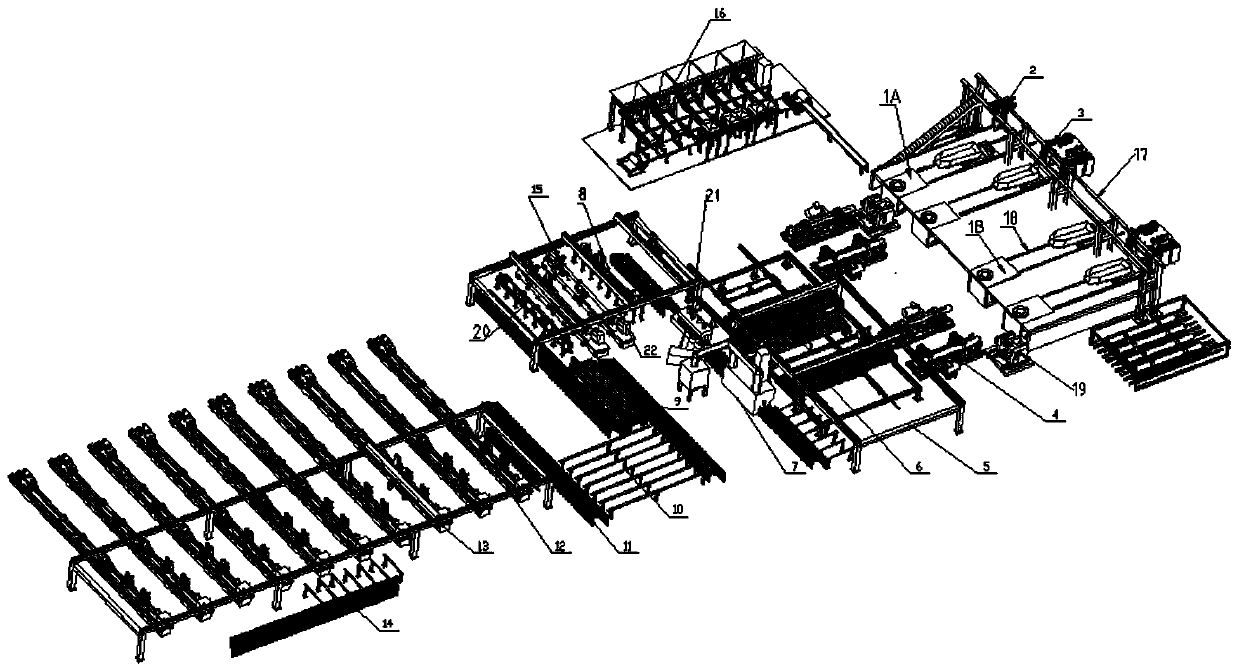

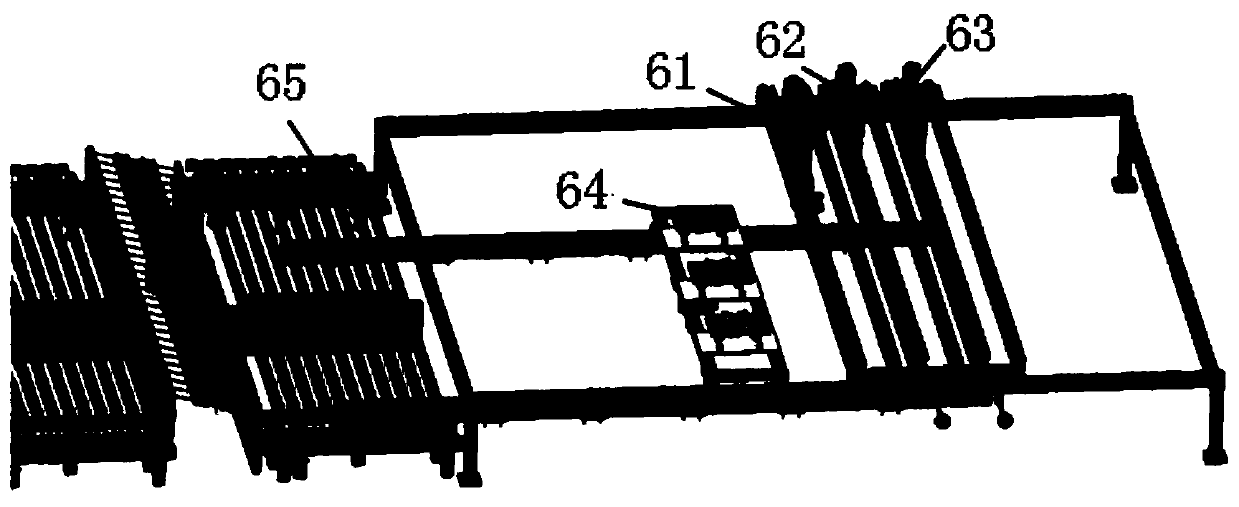

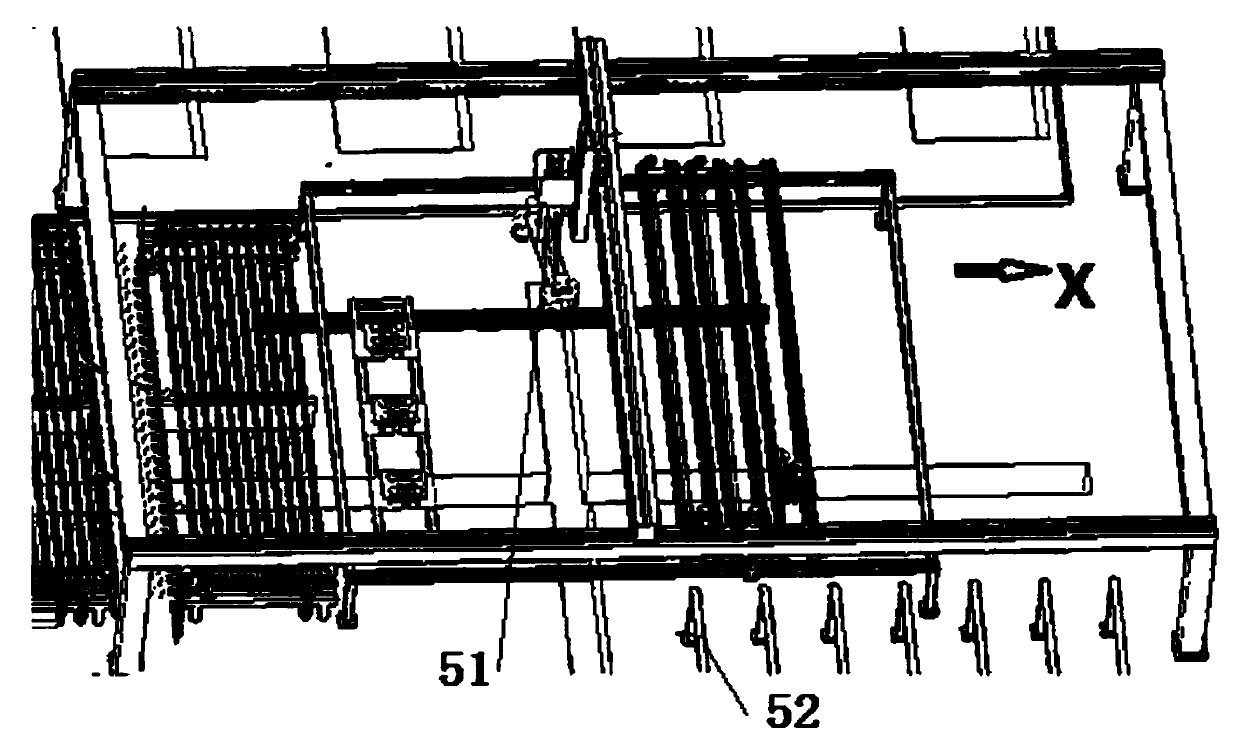

[0028] An automatic production line and production method for centrifugal casting pipes, including a batching warehouse 16, one end of the batching warehouse 16 is provided with a feeding device, and the feeding device includes a feeding robot 2, four feeding trolleys 3, and a first supporting robot 2 A track 17 and the second track 18 supporting the charging trolley 3, the other end of the second track 18 is provided with a smelting device, the smelting device includes a group of 1T melting furnaces 11 and a group of 2T melting furnaces, and a group of 1T melting furnaces includes two One 1T melting furnace 1A, one group of 2T melting furnaces including two 2T melting furnaces 1B, one group of 1T melting furnaces and one group of 2T melting furnaces including tundish trolley 19 and two centrifuges 4, two groups of melting furnaces with di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com