A detachable mounting structure for sub-frame and vehicle body

A technology for mounting structure and sub-frame, which is applied to the substructure, vehicle components, transportation and packaging, etc., can solve the problems of endangering the personal safety of drivers and occupants, the collision energy is not absorbed in time, and the deformation energy absorption space is small. Achieve the effect of reducing intrusion, avoiding further damage, and increasing the deformation energy absorption space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further specifically described below through an embodiment and in conjunction with the accompanying drawings.

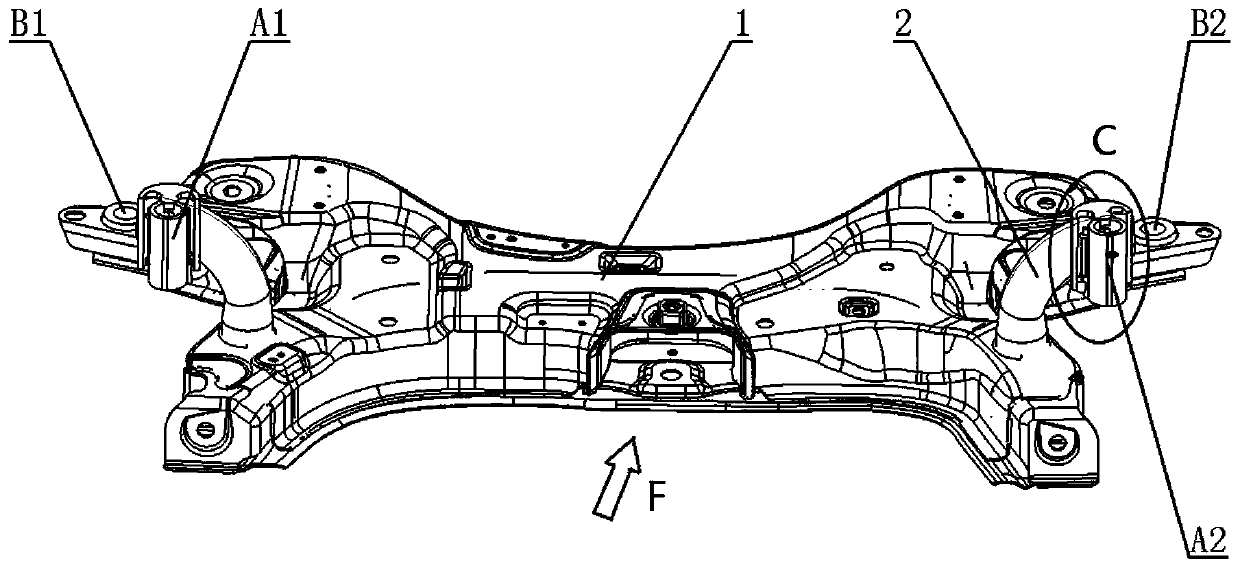

[0027] Such as figure 1 In the shown front subframe of the vehicle, the front subframe is connected to the vehicle body not shown in detail from below, and has four connection positions with the vehicle body, which are respectively connected to the corresponding positions of the vehicle body. Frame and body front connection points A1, A2 and two sub-frames and body rear connection points B1, B2. In this embodiment, the installation structure of this embodiment that can realize the detachment of the sub-frame from the vehicle body is used at the front connection points A1 and A2 of the front sub-frame. The mounting structure is welded at the horn 2 of the sub-frame body 1 .

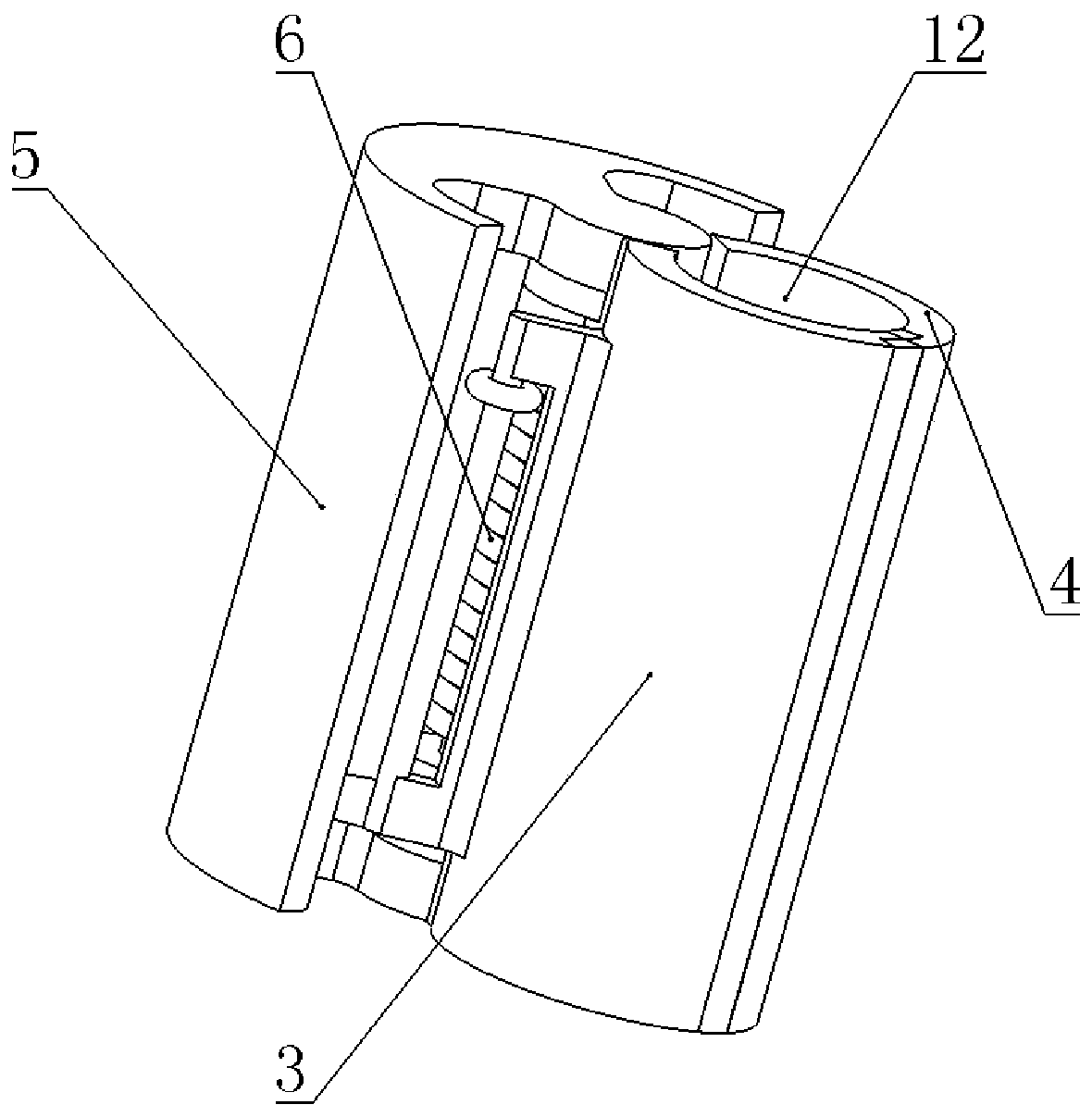

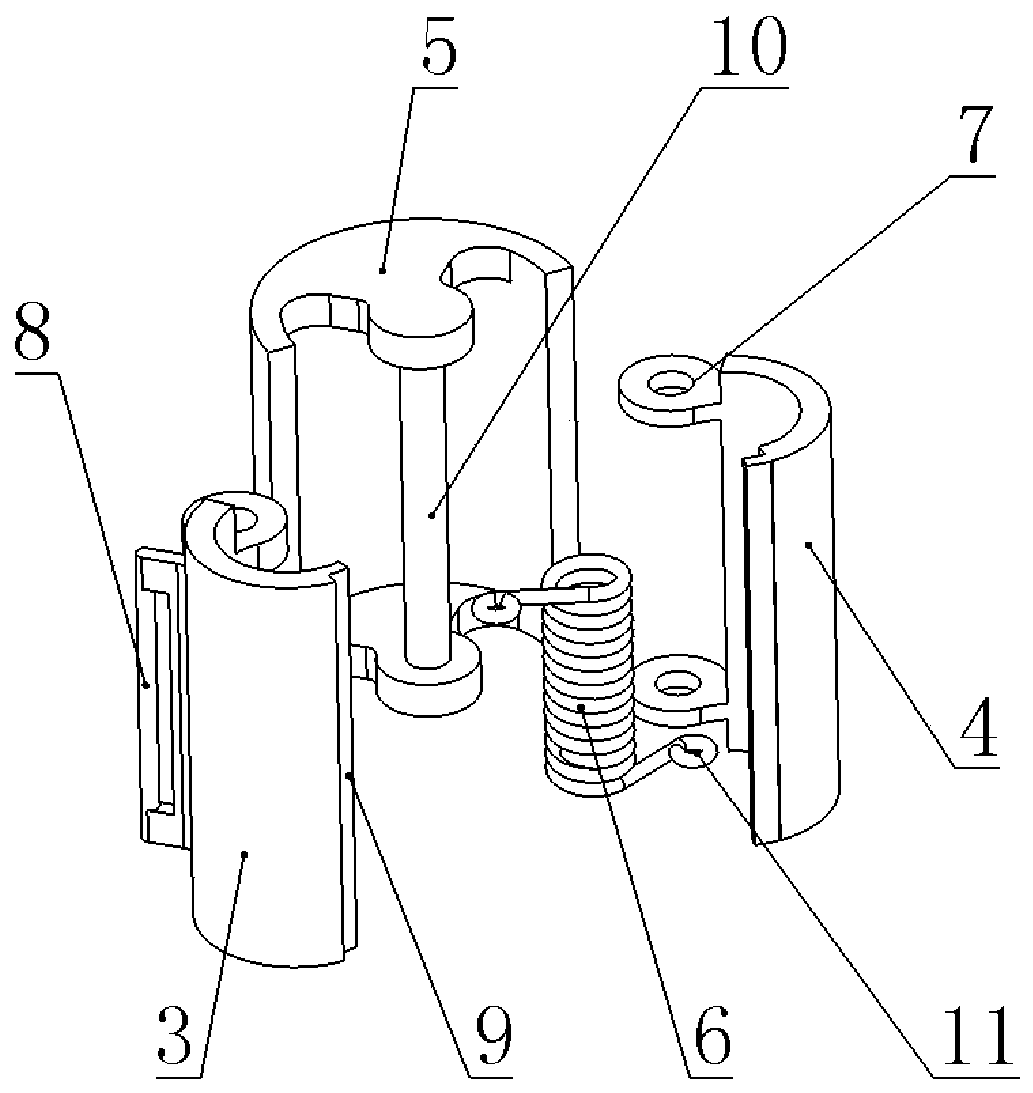

[0028] Such as figure 2 As shown, a detachable mounting structure for the subframe and the vehicle body includes an openable and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com