Pulping method of soymilk maker

A soymilk machine and a technology for pulping are applied in the field of pulping of soymilk machines, which can solve the problems of small capacity range of soymilk machine, increase the difficulty of program design, affect weighing accuracy, etc. The effect is basically the same, and the effect of improving the user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

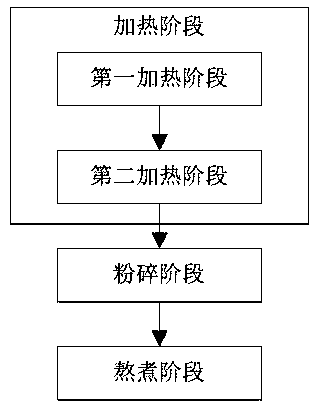

[0023] A pulping method for a soymilk machine, the soymilk machine includes a cup body for accommodating materials, a heating device for heating the materials, a temperature detection device for measuring the temperature of the materials, and a device for controlling the heating device and temperature The control device of the detection device. Of course, the soybean milk machine also includes a motor, and a crushing device driven by the motor to crush materials, and the control device controls the motor to perform corresponding work. At the same time, the soymilk maker is also equipped with a corresponding display device for the user to operate and remind the user. After the user performs a corresponding operation on the soymilk maker, the soymilk maker starts to execute the corresponding work flow according to the user's operation. For the pulping process of soybean milk machine, such as figure 1 As shown, it has three major pulping stages. Generally, the first stage is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com