Patents

Literature

49results about How to "Easy to pulp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

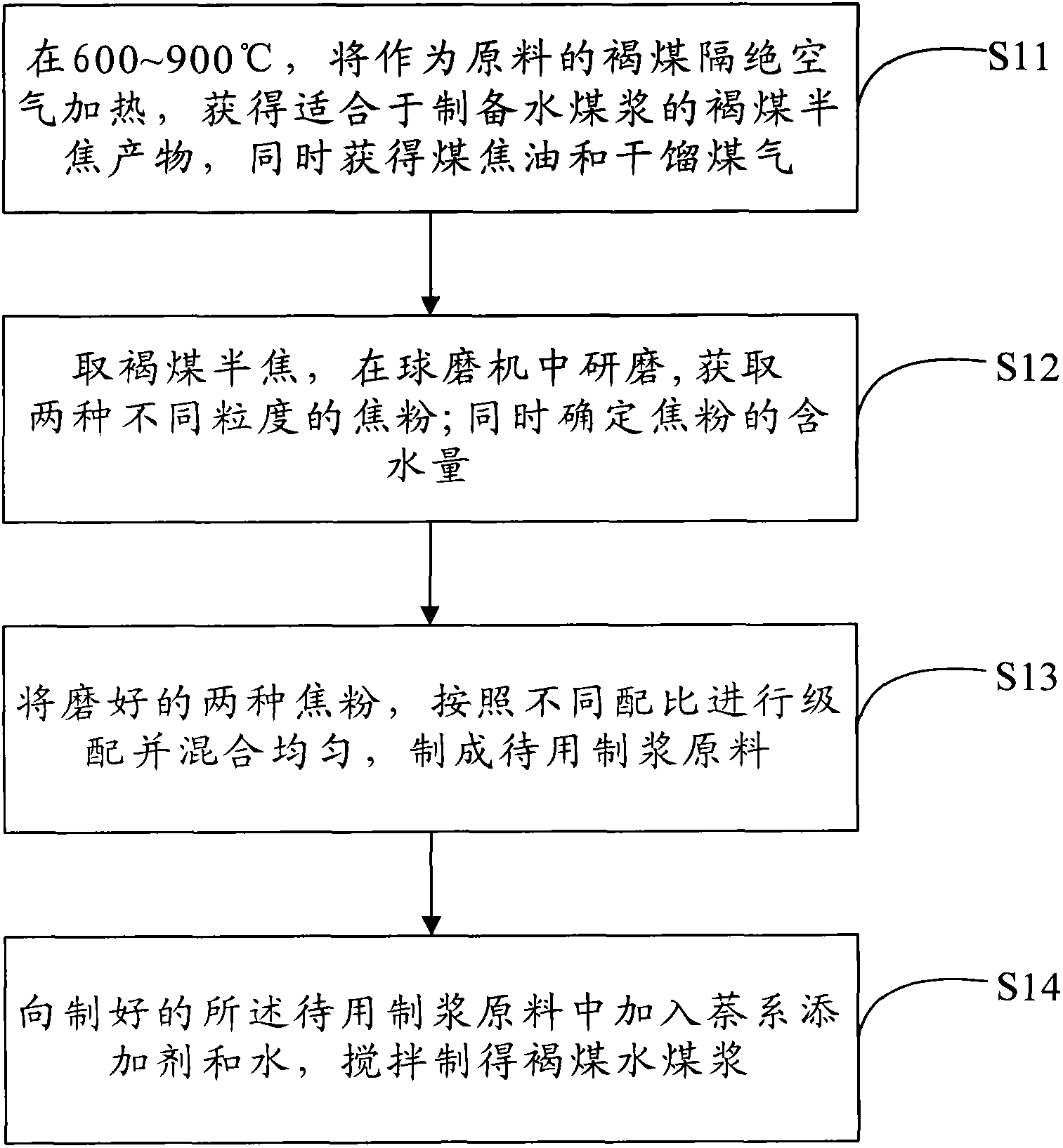

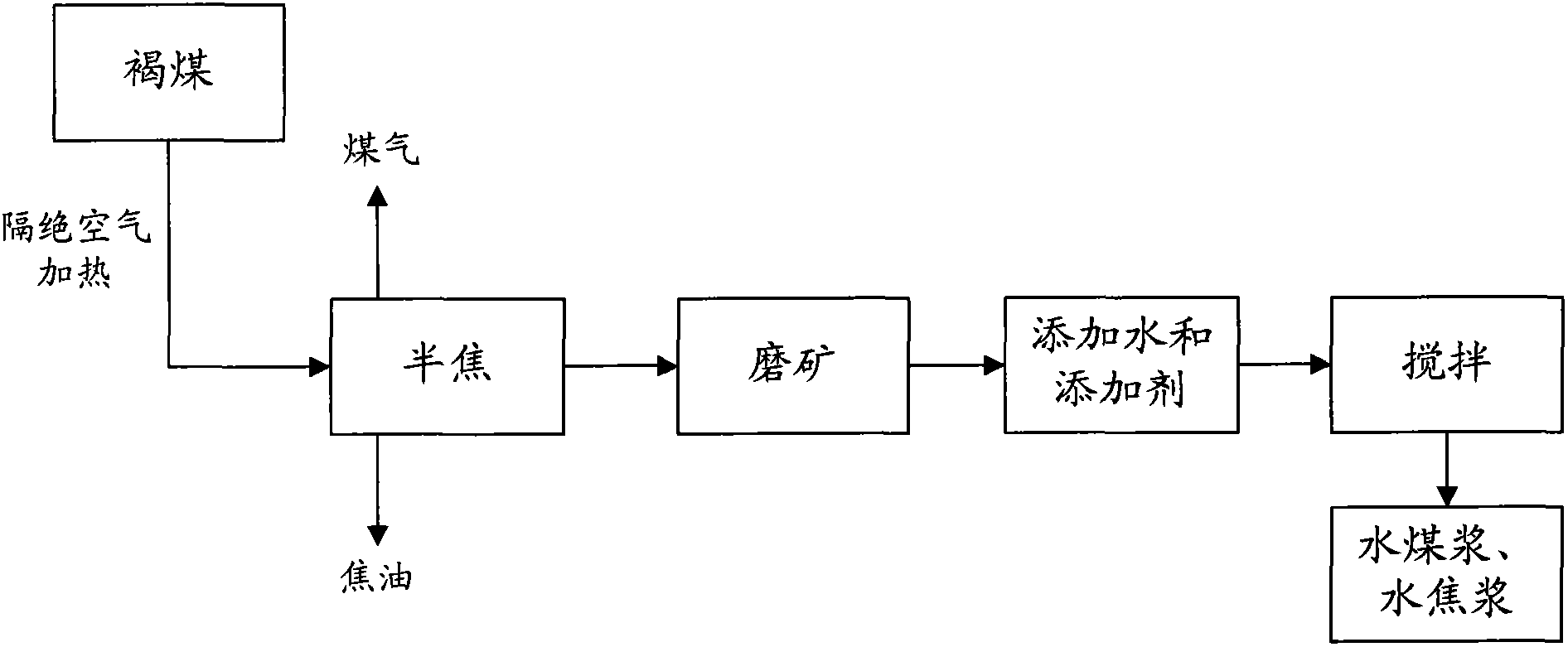

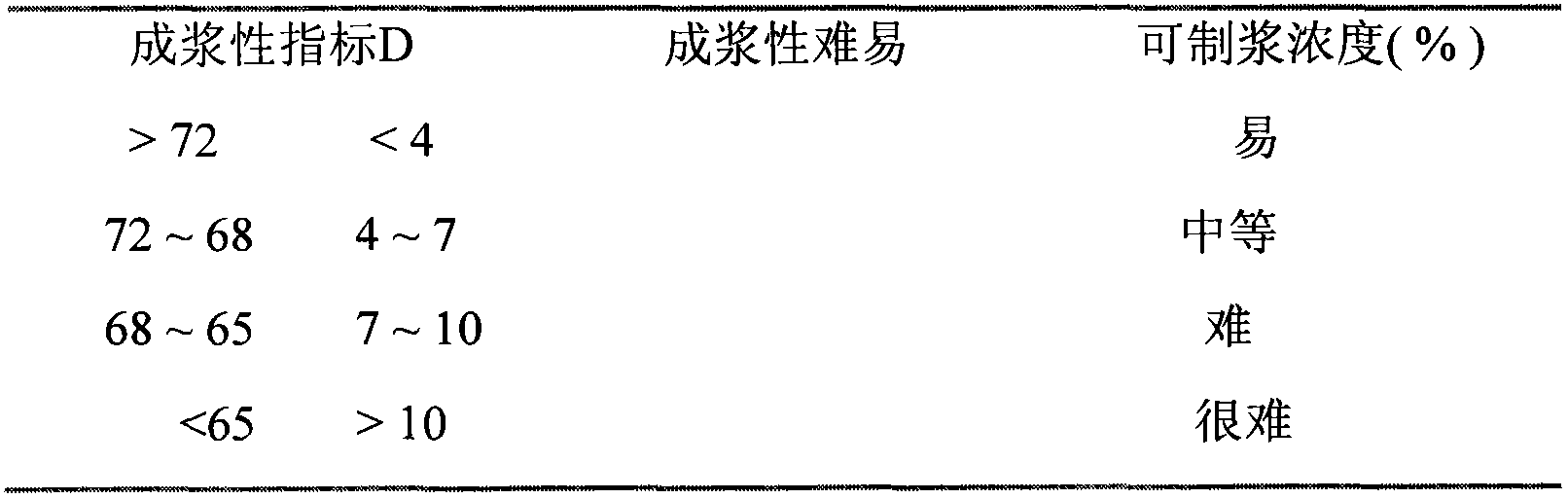

Method for preparing gasified coal water slurry by utilizing lignite

InactiveCN101914401AReduce moistureReduce volatilityLiquid carbonaceous fuelsSpecial form destructive distillationCoal waterBrown coal

The invention discloses a method for preparing gasified coal water slurry by utilizing lignite, comprising the following steps: isolating the lignite which is taken as a raw material from air and heating at the temperature of 600-900 DEG C to obtain a lignite semicoke product suitable for preparing the coal water slurry, coal tar and retort gas; taking the lignite semicoke; grinding the lignite semicoke in a ball grinding mill into two kinds of coke powders with different particle sizes; grading the two kinds of ground coke powers in different proportion and evenly mixing to prepare a stand-by pulping raw material; adding naphthalene additive and water in the stand-by pulping raw material; and stirring to prepare the lignite coal water slurry. In the method of the invention, dry distillation process is utilized, firstly tar with high addition value in the lignite is extracted to obtain high-quality retort gas and simultaneously obtain lignite semicoke the structure and the performanceof which are beneficial for pulping, thus improving the utilization value of the lignite and realizing the comprehensive utilization of the lignite.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

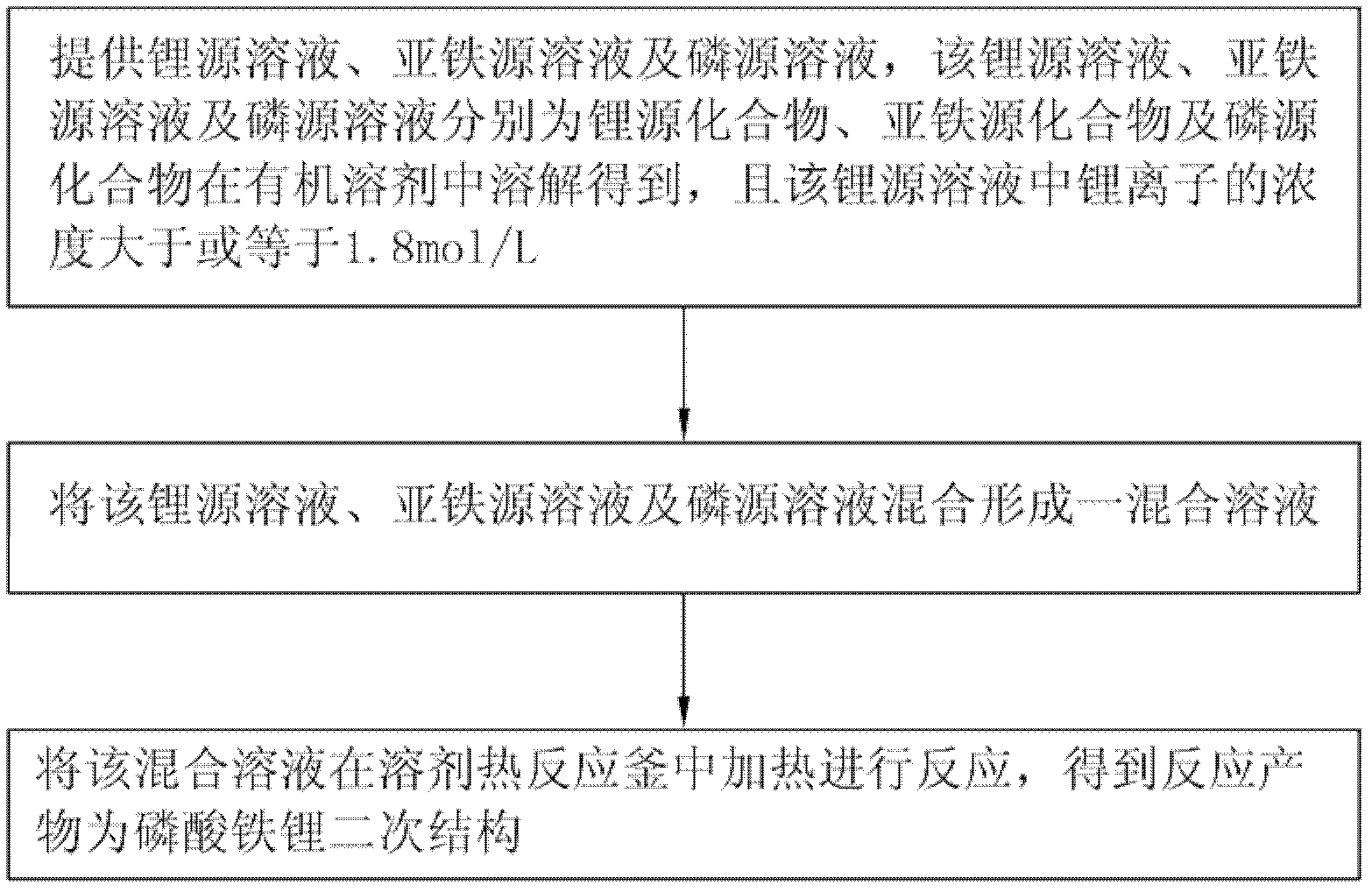

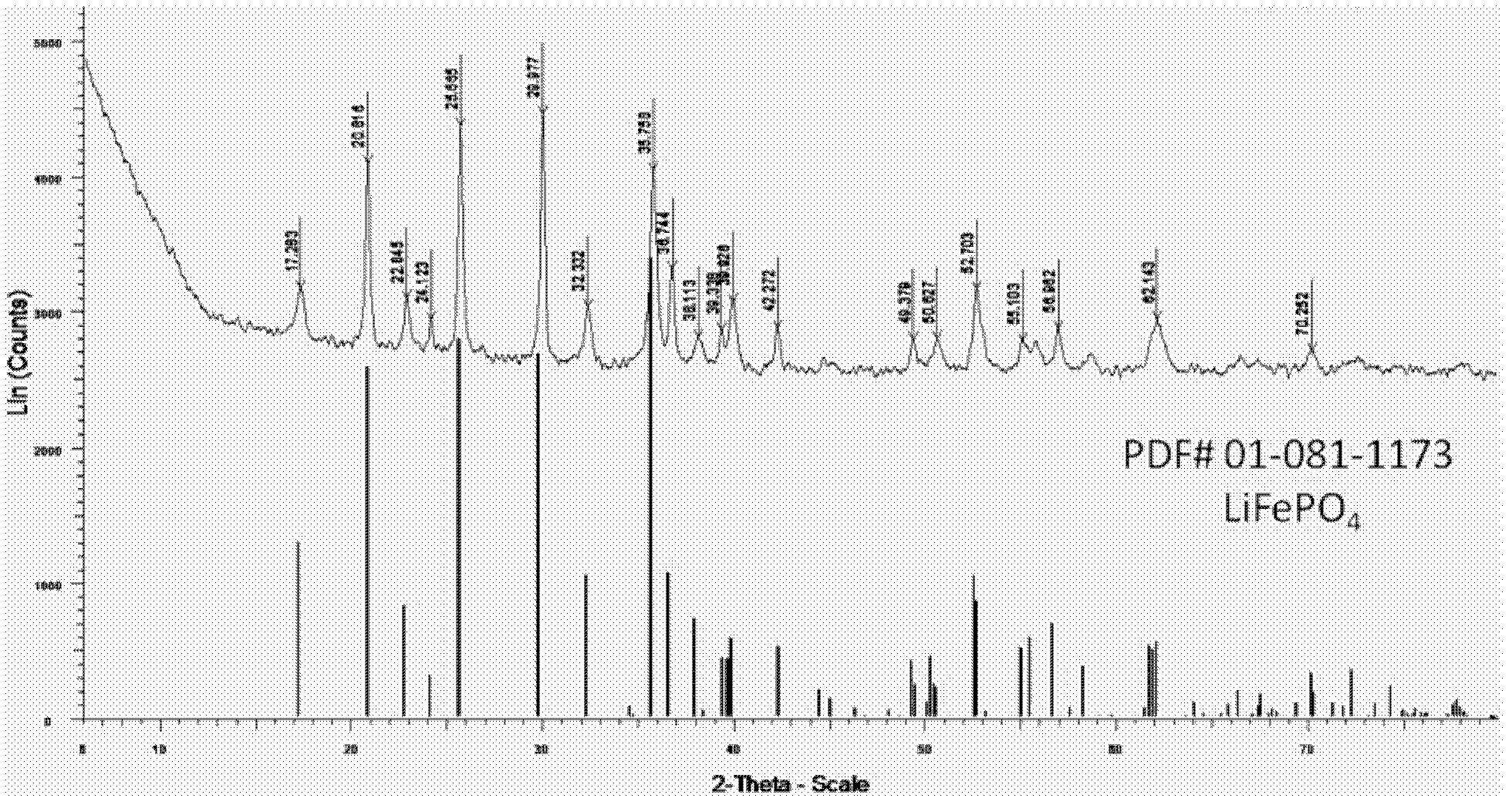

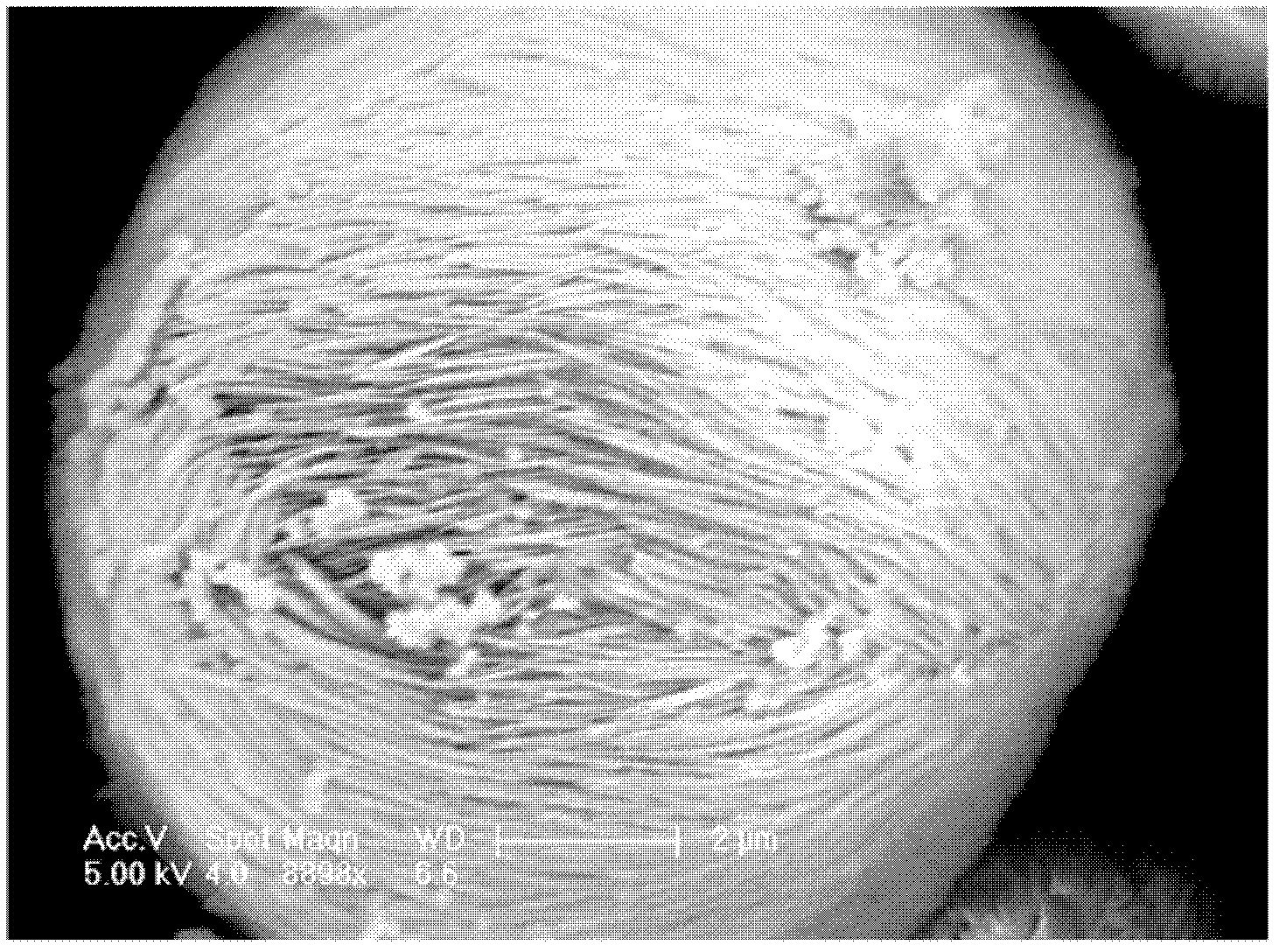

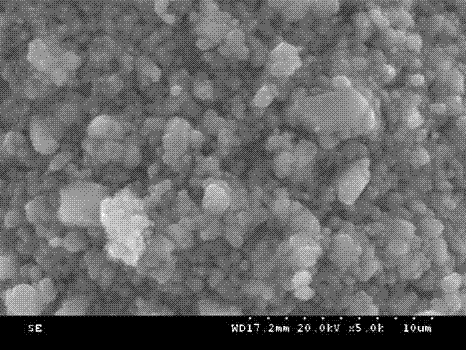

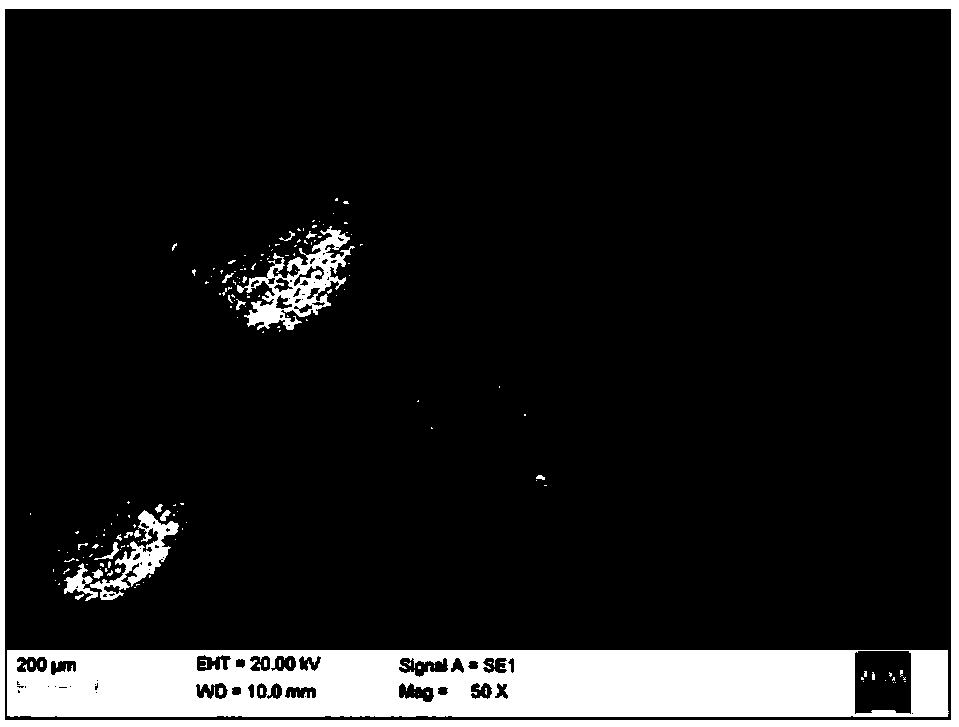

Lithium iron phosphate secondary structure, preparation method of the lithium iron phosphate secondary structure, and lithium ion battery

ActiveCN103137964AShorten the diffusion pathHigh bulk densityFinal product manufactureCell electrodesOrganic solventLithium iron phosphate

The invention relates to a preparation method of a lithium iron phosphate secondary structure. The preparation method comprises the following steps of 1, preparing a lithium source solution, a ferrous source solution and a phosphorus source solution by respectively dissolving a lithium source compound, a ferrous source compound and a phosphorus source compound in organic solvents, wherein the lithium source solution has the lithium ion concentration more than or equal to 1.8mol / L, 2, mixing the phosphorus source solution and the ferrous source solution into a first solution, and adding the lithium source compound into the first solution to obtain a second solution, and 3, heating the second solution in a solvothermal reactor for a reaction. The invention also relates to the lithium iron phosphate secondary structure and a lithium ion battery.

Owner:TSINGHUA UNIV +1

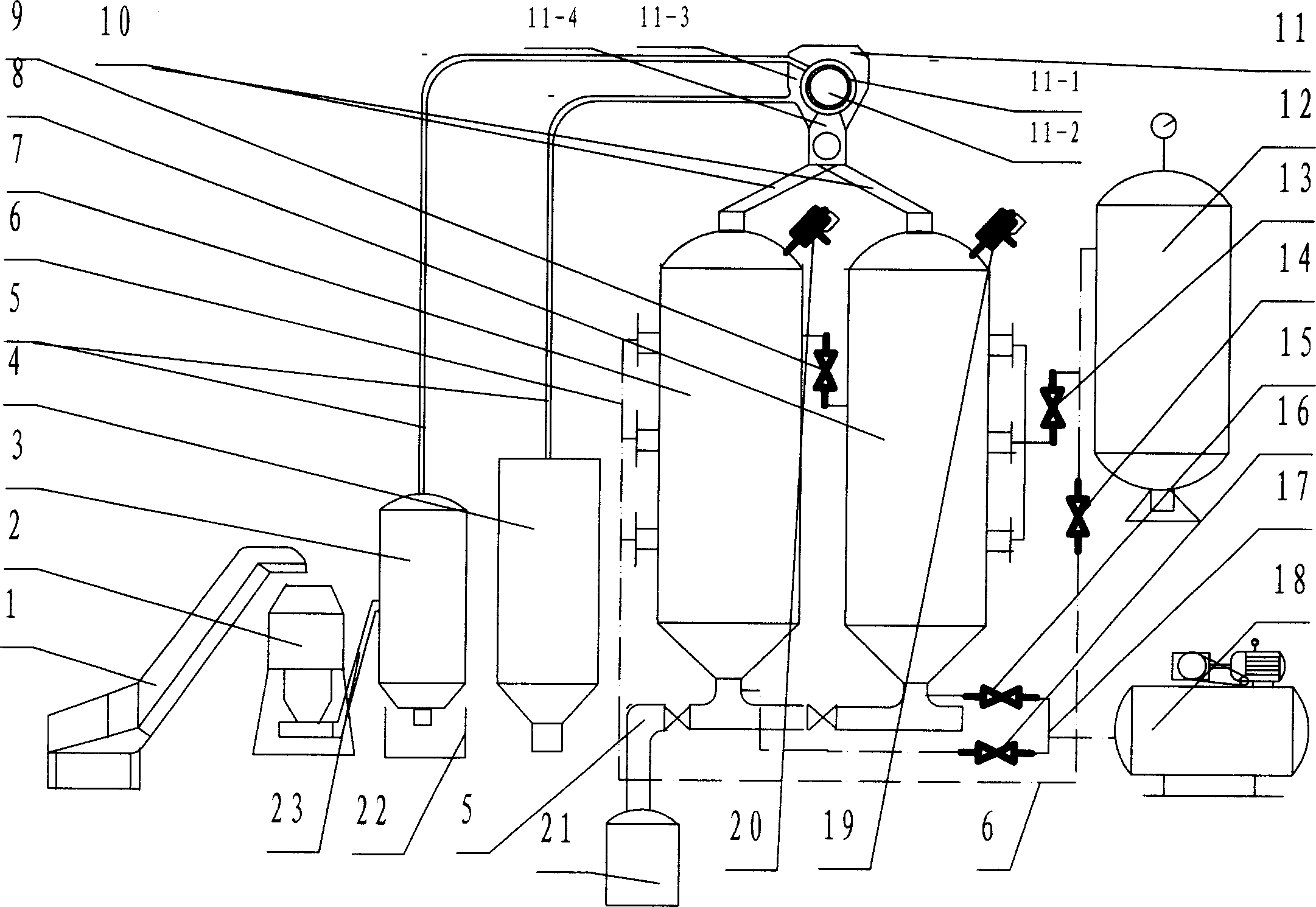

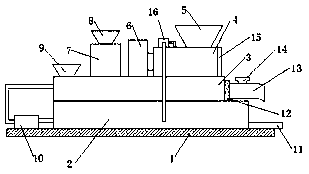

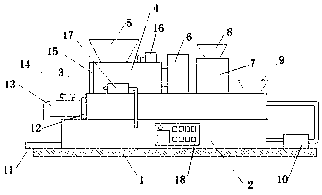

Method and equipment for producing paper pulp by gases mixed explosion

InactiveCN1737253AReduce pollutionEasy to pulpCellulose material pulpingRaw material divisionProduct gasGas mixing

This invention discloses a gas mixing burst paper making method, in addition to a device. The method comprises the following steps: a) straw-rope spinning by the straw-rope spinning machine; b) removing the heavy war by the air-separator; c) removing the lightweight war and dust by the ash separator; d) boiling by the boiler, introducing the steam in the boiler to other boiler to use again; e) filling pressed air to the boiler after introduced steam and bursting to make slurry. The process can decrease the pollution to environment; in addition, it can increase the comprehensive utilization ratio of raw material.

Owner:蔡文翀 +1

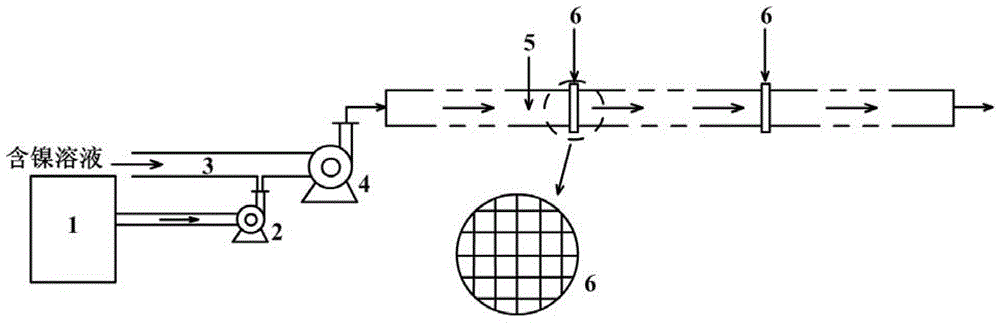

Method and device for deeply removing copper of nickel thiocarbonate from nickel-containing solution

InactiveCN102719671AFully mixed reactionEliminates unwanted effects of lower densityProcess efficiency improvementSlagCopper

The invention discloses a method and device for deeply removing copper of nickel thiocarbonate from a nickel-containing solution. Substantially, the nickel thiocarbonate after pulping is used as a copper removal agent; and the copper removal agent is automatically added through a mechanical mixing pump and is uniformly mixed with the nickel-containing solution in a pipeline reactor to remove copper. The method can realize continuous copper removal in the closed environment, the copper removal efficiency is high, and the concentration of the liquid cooper after copper removal is lower than 3mg / l. The copper-nickel ratio in the copper removal slag is greater than 15, thereby completely meeting the production requirements.

Owner:CENT SOUTH UNIV

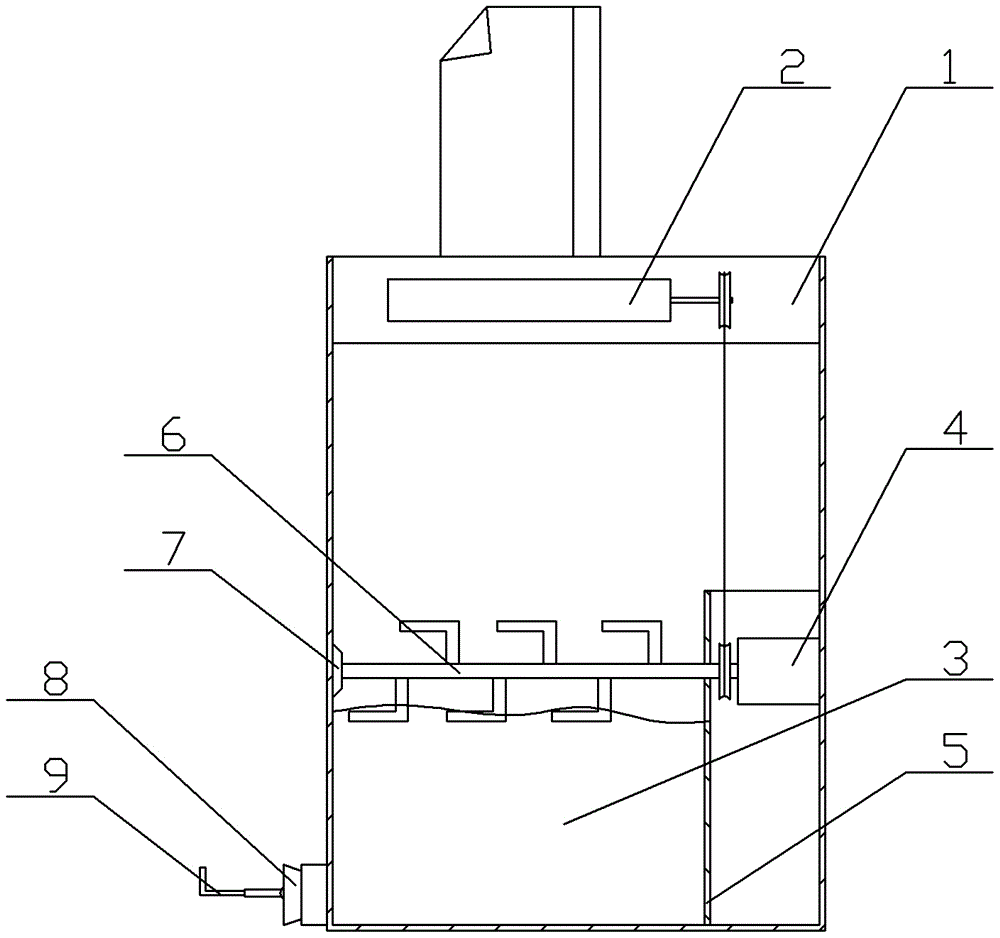

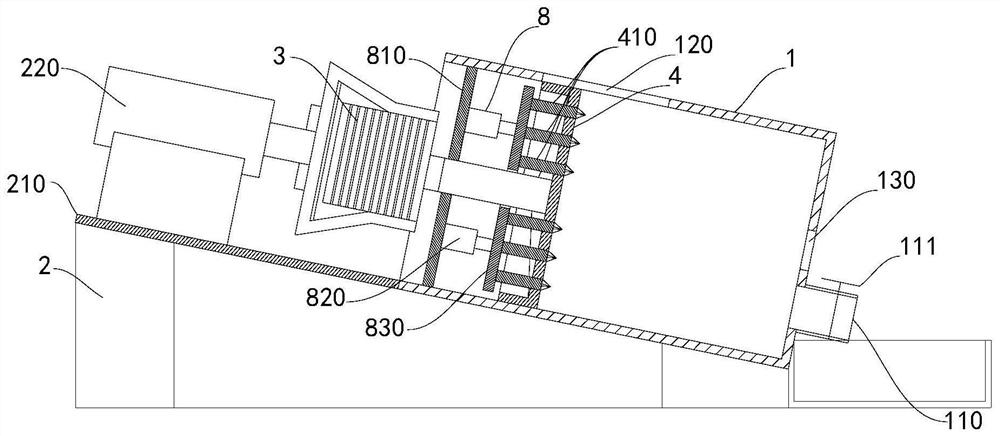

Pulping device of paper shredder

The invention discloses a printed matter processing device, and particularly relates to a pulping device of a paper shredder. The pulping device of the paper shredder comprises a paper shredder shell and a cutter shaft which is used for shredding paper and is arranged on the upper part of the shell, and the pulping device of the paper shredder is characterized in that a pulping area is formed at the lower part of the shell and comprises a paper pulp storage box which is arranged below the cutter shaft and an electromotor which is installed beside the paper pulp storage box, the electromotor is horizontally arranged, the end part of an output shaft of the electromotor is directly connected with a stirring crushing paddle, the stirring crushing paddle is provided with bent stirring teeth, the rotary surface of the stirring crushing paddle contacts the paper pulp storage box, the output shaft of the electromotor is also provided with a belt pulley, the belt pulley is connected to the cutter shaft through a belt, and an openable pulp discharging hole is formed in the bottom of the paper pulp storage box. By adopting the pulping device of the paper shredder of the technical scheme, the floor area for the shredded paper is relatively small, and the information leakage can be avoided.

Owner:DINGSHENG CORP

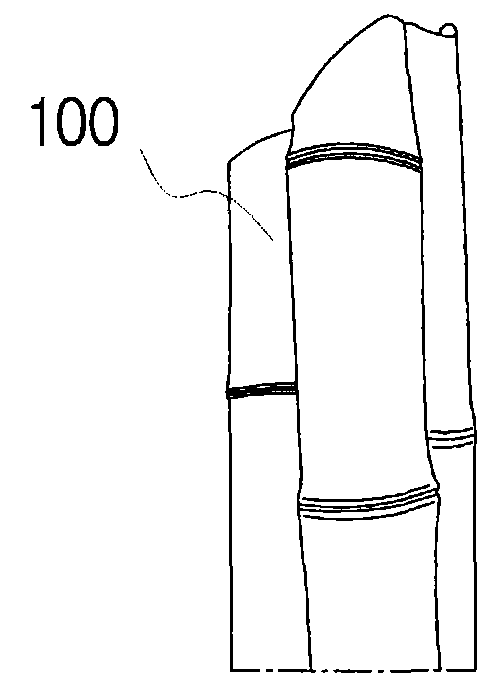

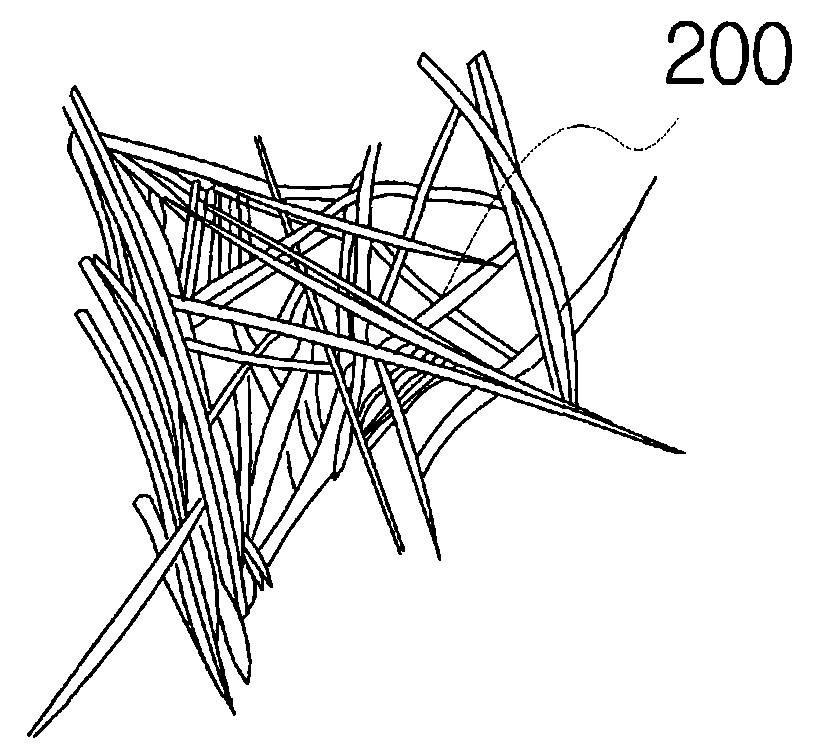

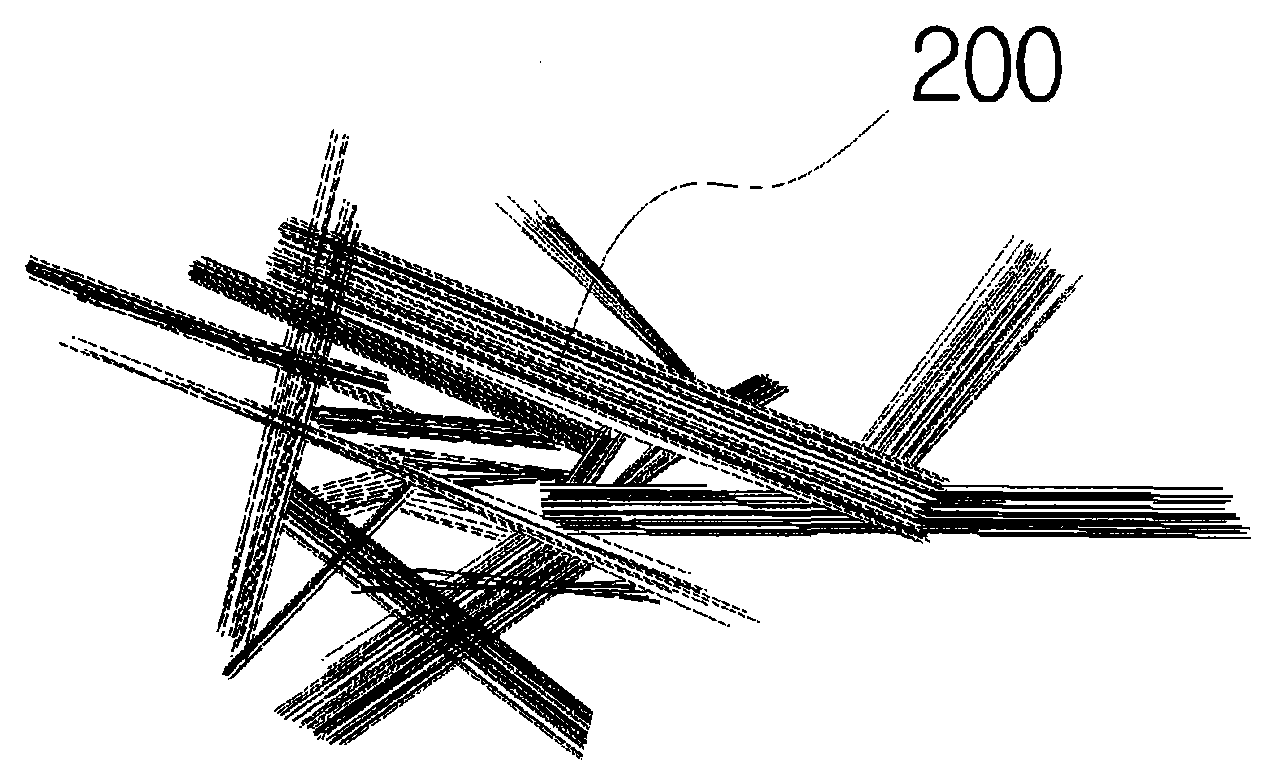

Manufacturing method of bamboo chip for manufacturing the solubility pulp and thereof

InactiveCN101583758AEasy to pulpEasy to packNon-woody plant/crop pulpFinely-divided material pretreatmentSolubilityProduction rate

There are provided a method for manufacturing a bamboo chip for a soluble pulp and a bamboo chip manufactured therefrom, the bamboo capable of improving their productivity and obtaining high-quality products, as well as manufacturing the soluble pulps economically and environment-friendly. The present invention provides a method for manufacturing bamboo chips including steps of: softening bamboo stems and giving bulkiness in a process of manufacturing bamboo chips by pressing and crushing the bamboo, which has compact and structural characteristics in nature, with a convex roller to tear the bamboo stems into pieces in a longitudinal direction, and simultaneously cutting the bamboo stems into bamboo chips having desired lengths; removing a large amount of unnecessary substances, such as lignin, thin- wall tissues, joints, silicified barks and the like, in celluloses in the above-mentioned process so as to facilitate easy penetration of chemical agents and effectively remove lignin and hemicellulose in a process for extracting a pulp; and pressing and bending the bamboo chips into certain shapes to package the bamboo chips, and transporting the bamboo chips to a container or a bulk carrier in an economic manner.

Owner:艾比葛帕有限公司

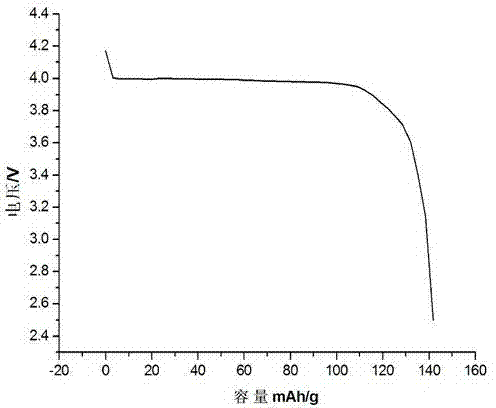

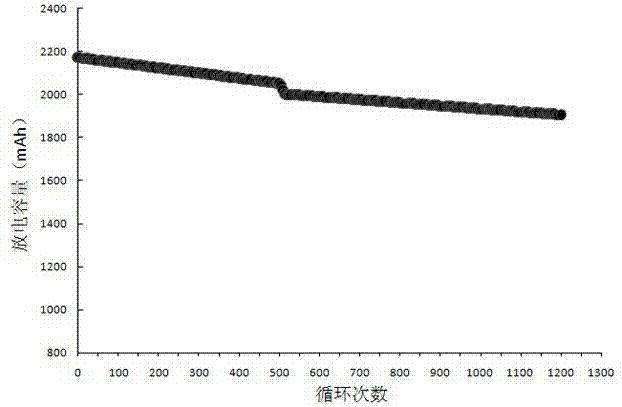

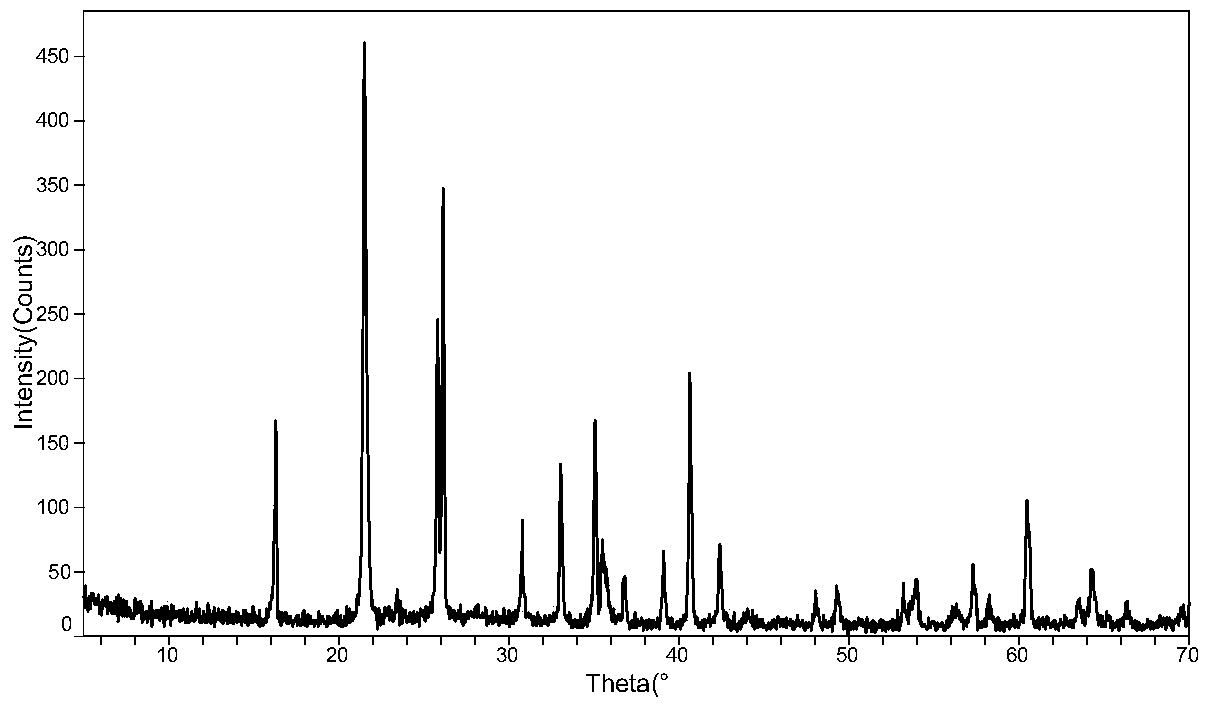

Metal-doped oxidative conductive carbon black cladded lithium manganese phosphate and preparation method thereof

The invention discloses metal-doped oxidative conductive carbon black cladded lithium manganese phosphate which is prepared by taking a lithium source compound, a manganese source compound, a phosphorus source compound, a metal dopant and a carbon source as raw materials, wherein the carbon source is oxidative conductive carbon black; the metal-doped oxidative conductive carbon black cladded lithium manganese phosphate has a chemical formula of LiMxMn[1-x]PO4 / C, wherein M is a metal doped element and is not less than 0.001 and not more than 0.1. The metal-doped oxidative conductive carbon black cladded lithium manganese phosphate is high in capacity, excellent in performance, good in circling stability and easy to disperse in water. The invention also provides a preparation method of the metal-doped oxidative conductive carbon black cladded lithium manganese phosphate. The preparation method mainly comprises the following steps: (1) preparing the oxidative conductive carbon black; and (2) preparing the metal-doped oxidative conductive carbon black cladded lithium manganese phosphate. The preparation method is simple in step and low in cost; the prepared metal-doped oxidative conductive carbon black cladded lithium manganese phosphate product is uniform in grain size, high in purity and excellent in electrochemical performance.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

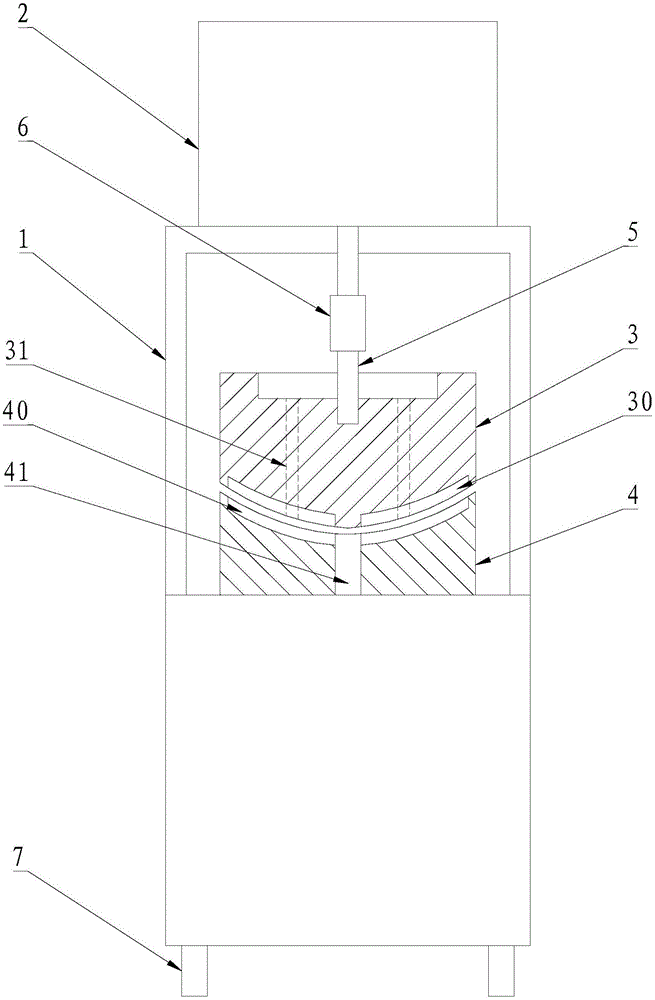

Cereal grinding method

ActiveCN106391201AImprove securityImprove stabilityCocoaGrain treatmentsPulp and paper industrySlurry

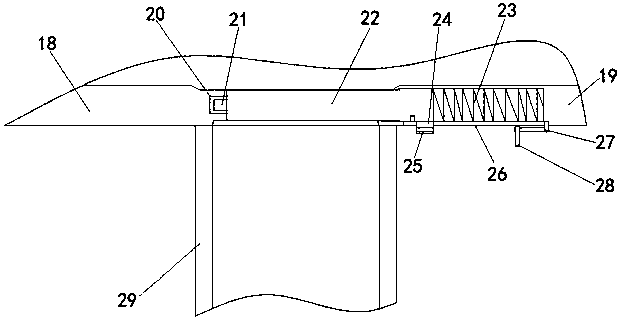

The invention relates to a cereal grinding method. The cereal grinding method comprises the steps that 1, a cereal grinder is provided, specifically, a motor of the cereal grinder is located above a grinding plate, an output shaft of the motor is connected with an upper grinding plate body and drives the upper grinding plate body to rotate, the lower surface of the upper grinding plate body is an outwards convex arc face, the upper surface of a lower grinding plate body is an inwards concave arc face matched with the outwards convex arc face, and a pulp outlet enabling the upper surface and the lower surface of the lower grinding plate body to communicate is vertically formed in the center of the lower grinding plate body; and 2, cereals and water are added into the grinding plate via a feed inlet, the motor is started and drives the upper grinding plate body to rotate, the material is crushed and ground fine through cooperation of the upper grinding plate body and the lower grinding plate body, pulp is generated, and the pulp flows to the pulp outlet along the inwards concave arc face to be discharged. According to the cereal grinding method, cereal grinders of different structures are adopted for grinding, grinding safety and rotation stability of the upper grinding plate body are improved, a dense pulp product obtained through grinding has a delicate taste, quality is stable, pulp waste is greatly reduced, pulp discharge is easy, and the method can meet the use requirement for small-scale grinding.

Owner:卓锦华

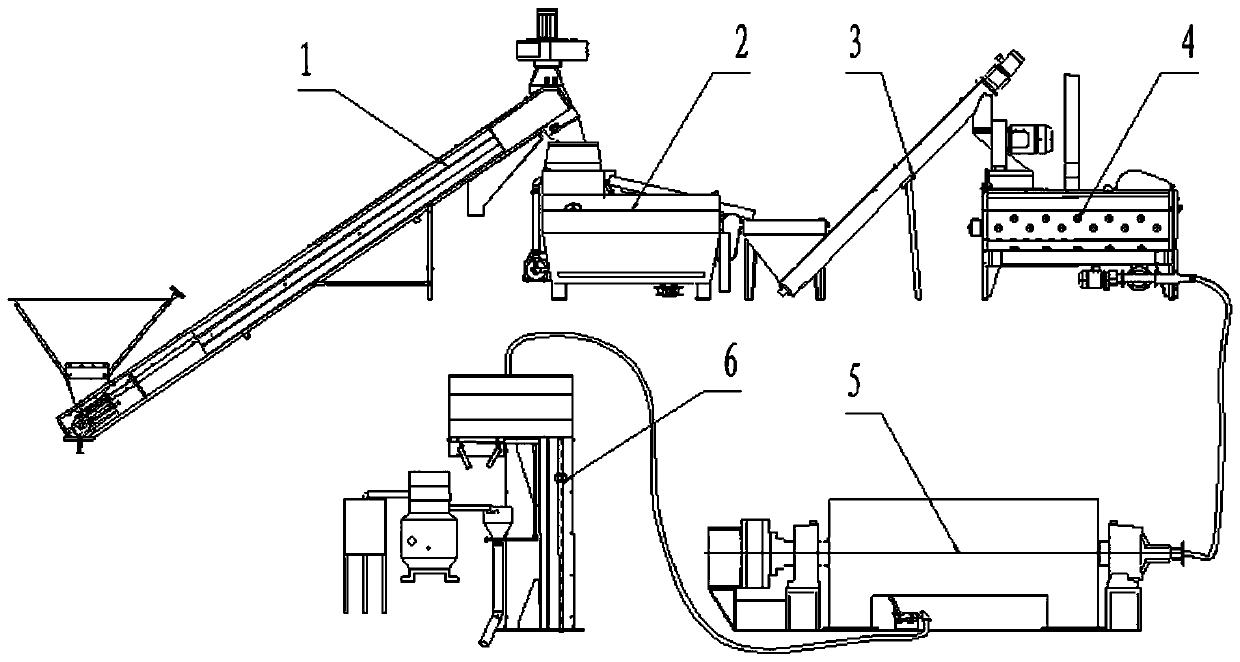

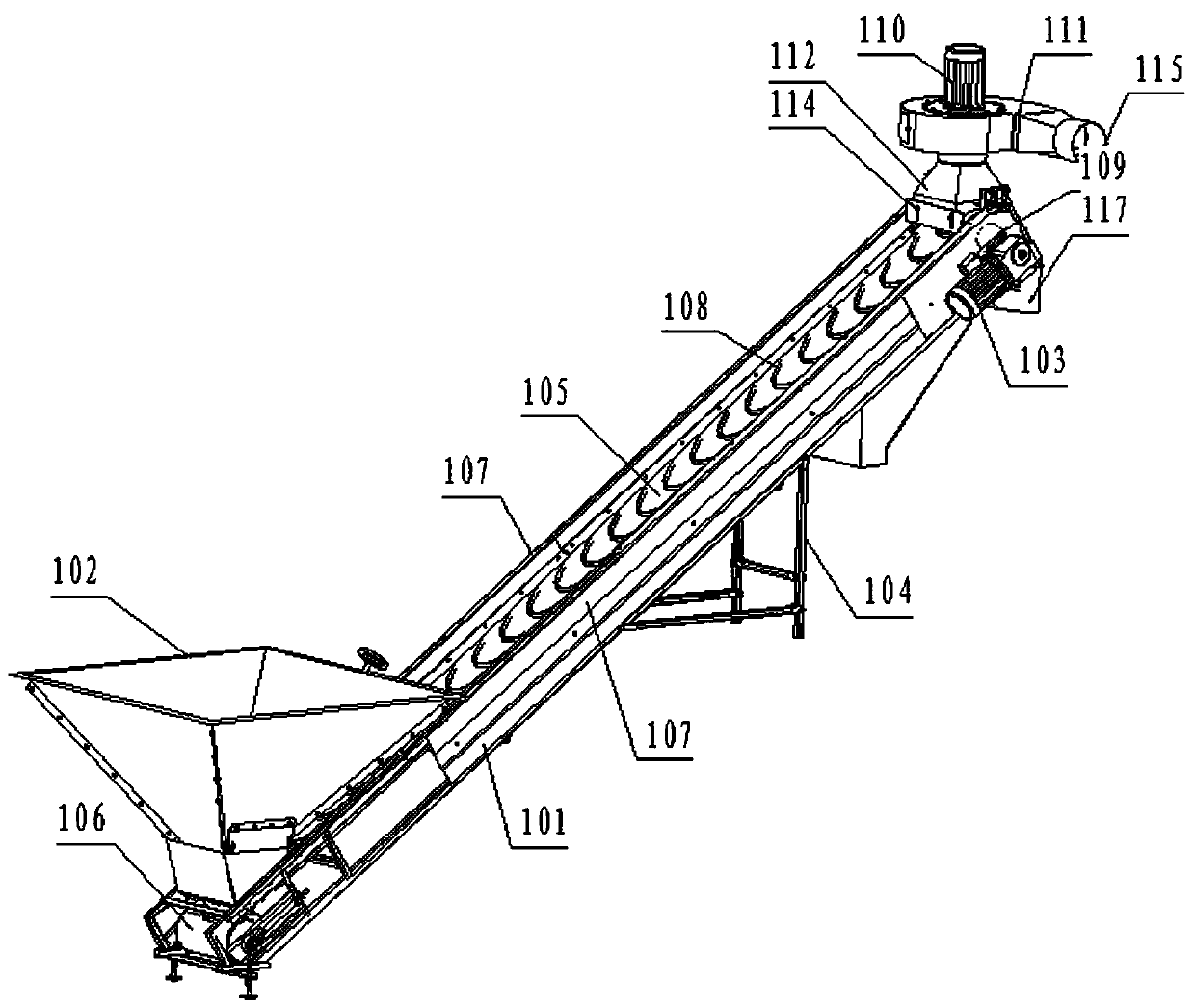

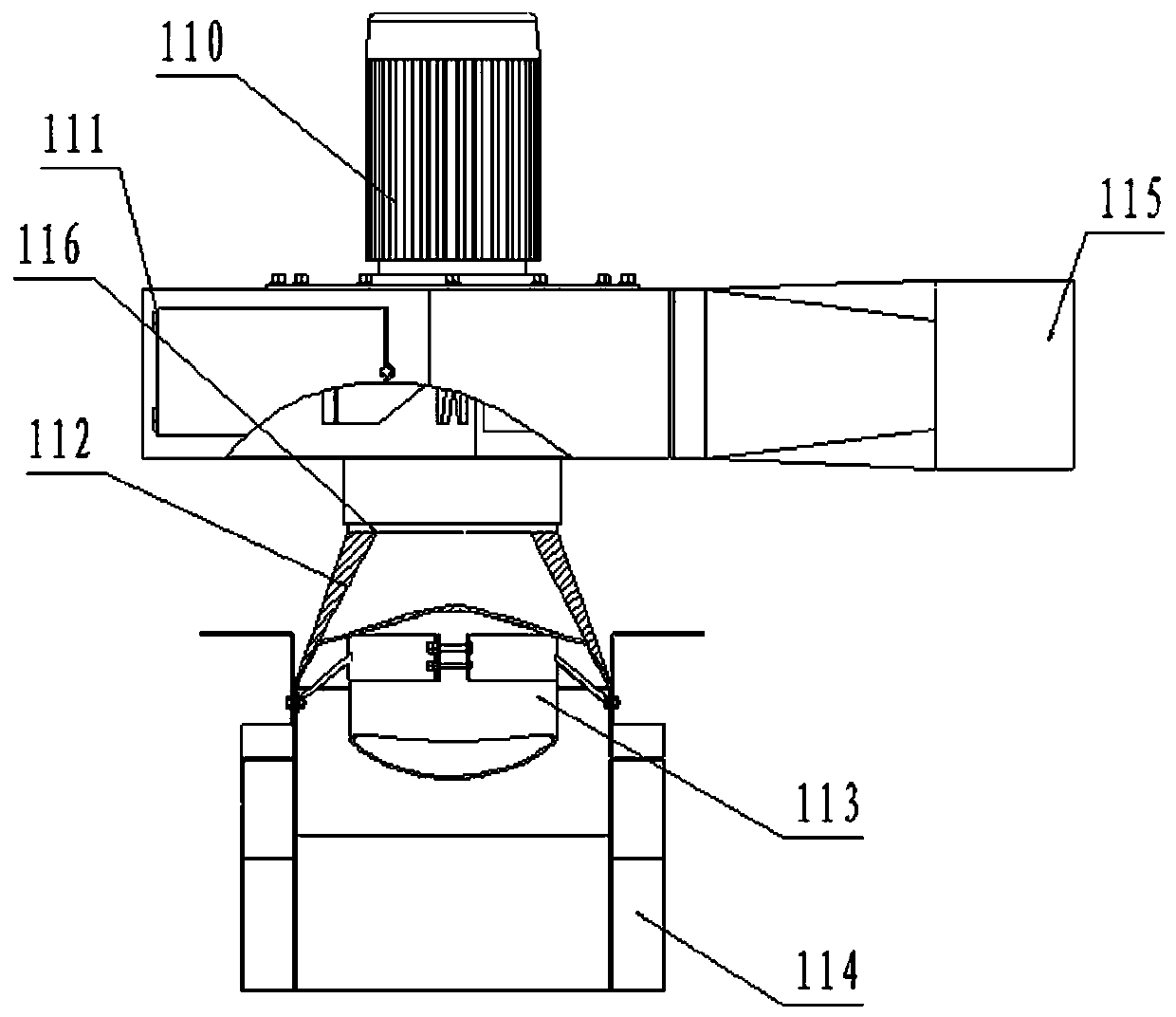

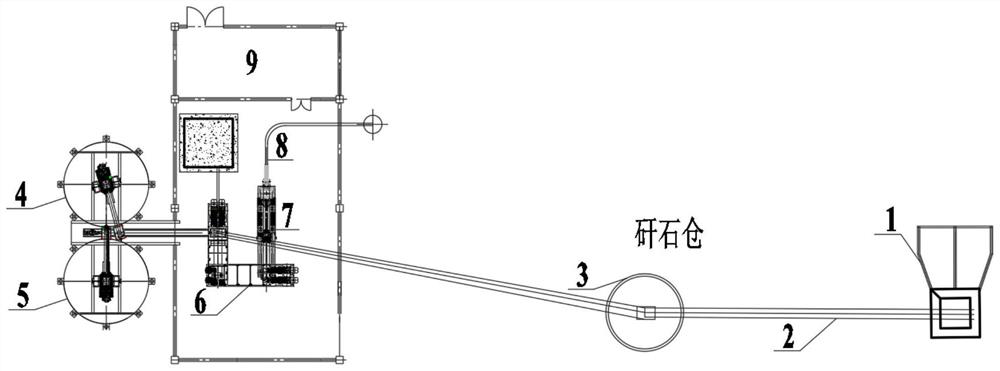

Olive oil production line

ActiveCN107904001AEvenly brokenOvercome the side-to-side swing phenomenonFatty-oils/fats refiningFatty-oils/fats productionProduction lineElectrical control

The invention discloses an olive oil production line, comprising an electric control system, and a feeding and winnowing device, a cleaning and screening device, a spiral feeding device, a fusion device, a separating device and a purifying device which are successively arranged on the production line. Olive fruit is poured into the feeding and winnowing device to remove leaves and dust, and then enters the cleaning and screening device for cleaning and screening; the cleaned olive fruit falls into the spiral conveying device and is spirally lifted to fusion device of the production line by thespiral conveying device; the olive fruit undergoes crushing, stirring and fermentation, and sufficient fusion in the fusion device; pulp obtained after stirring fermentation is conveyed to the separating device of the production line to completely separate oil-water and pomace in the pulp; and the screened oil-water is completely conveyed to a storage unit in the purifying device and then entersa disc separator for high-speed separation to produce a pure high-quality oil product. With such a technical scheme, the olive oil production line has low cost, ensures the axis parallelism of rollers, is smooth in operation, good in dust removal effect, thorough in cleaning, crushing, stirring and fusion, and high in yield, and ensures oil quality.

Owner:ANHUI SAIERTE CENTRIFUGE

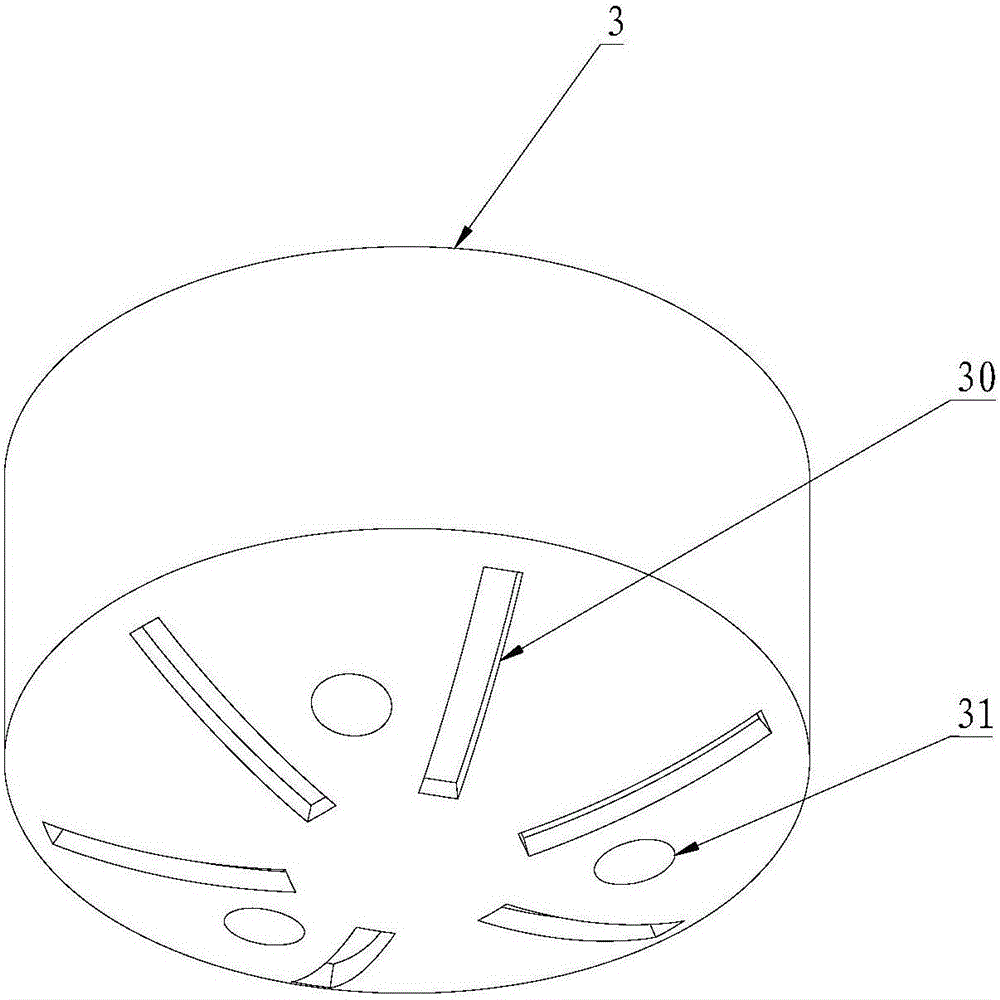

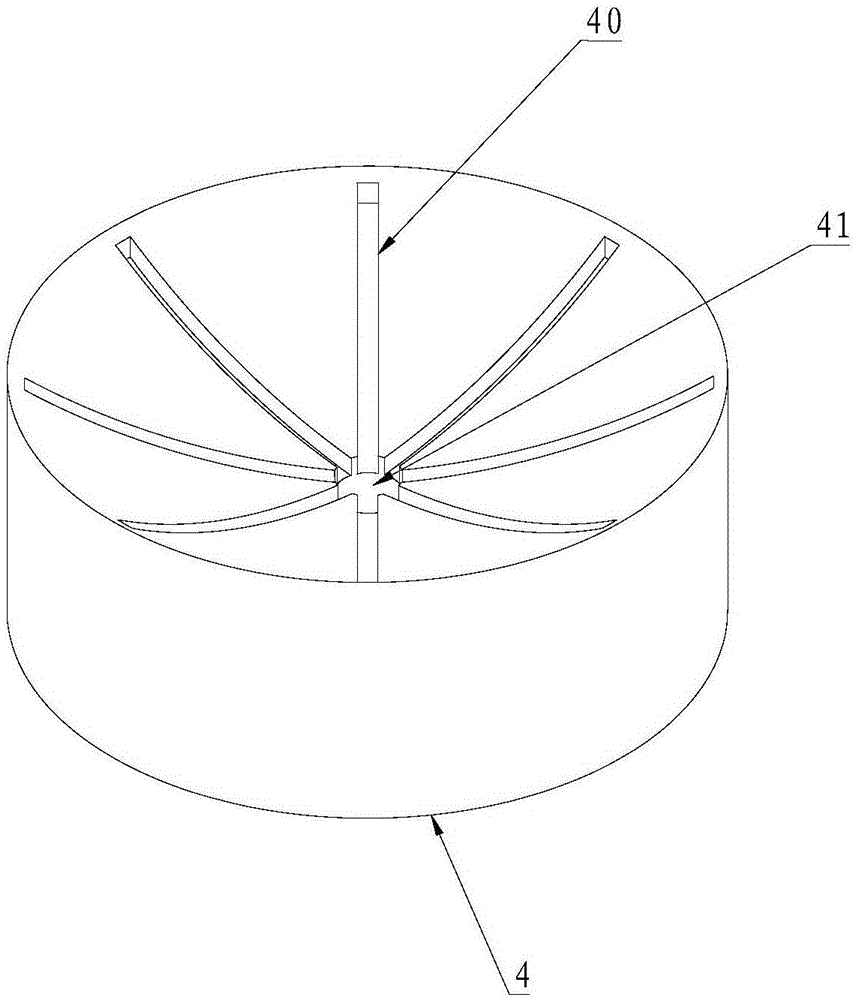

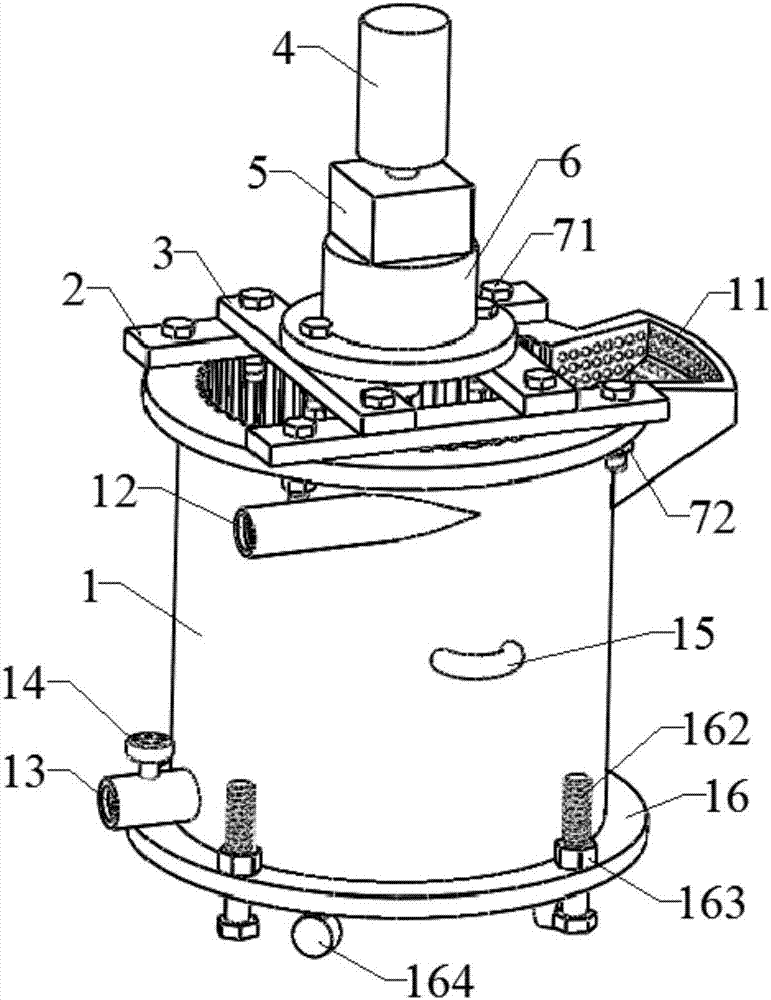

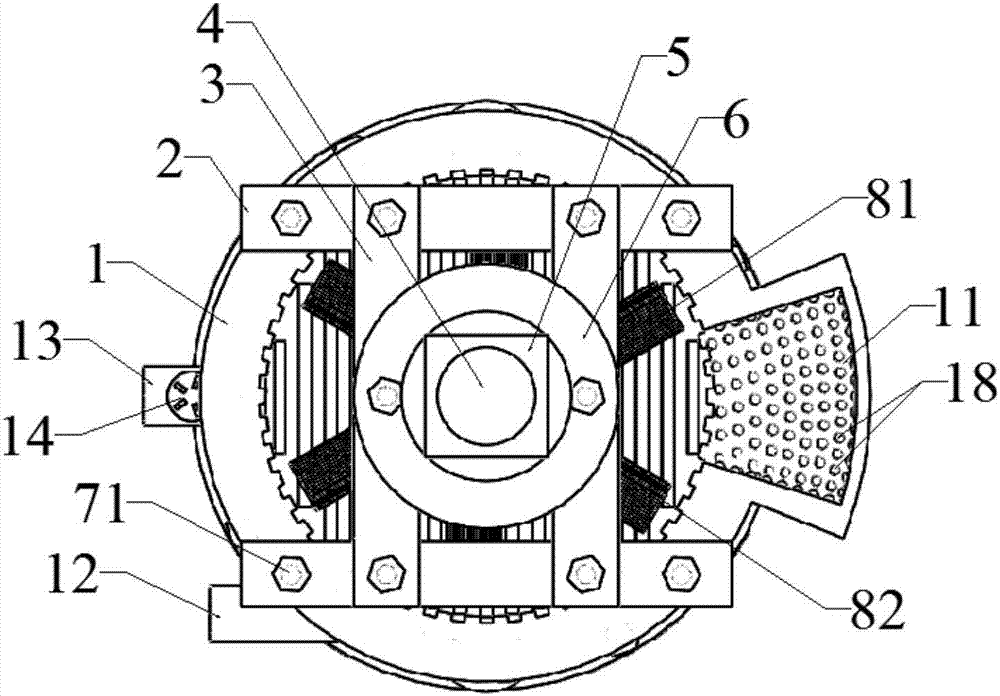

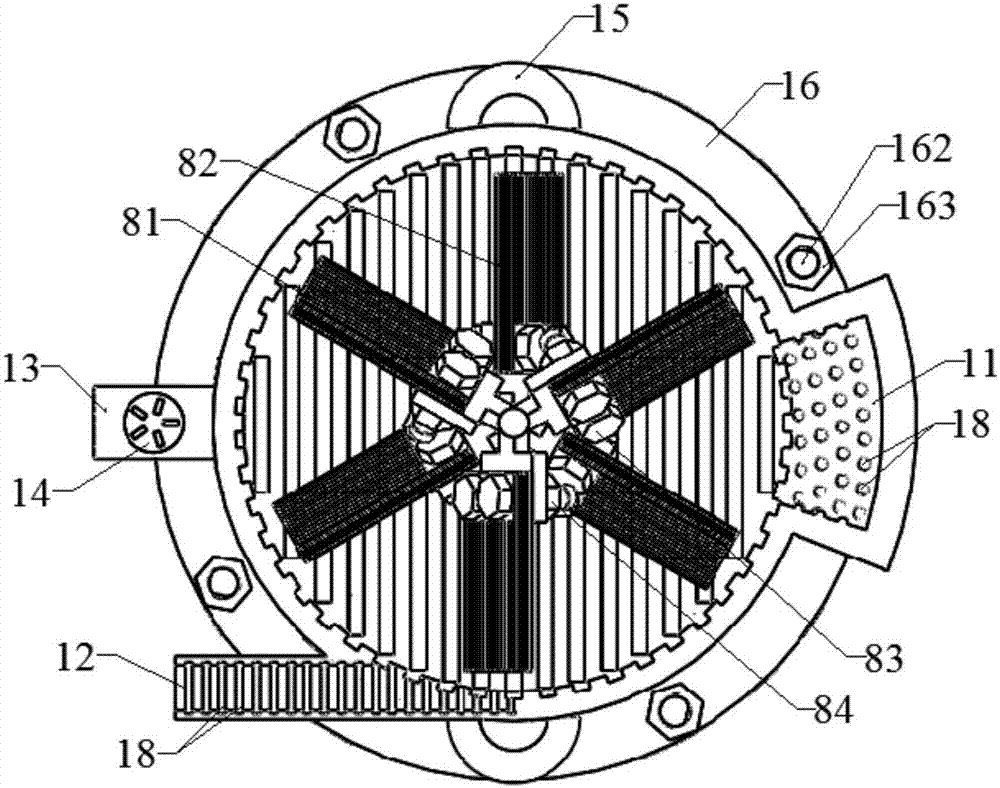

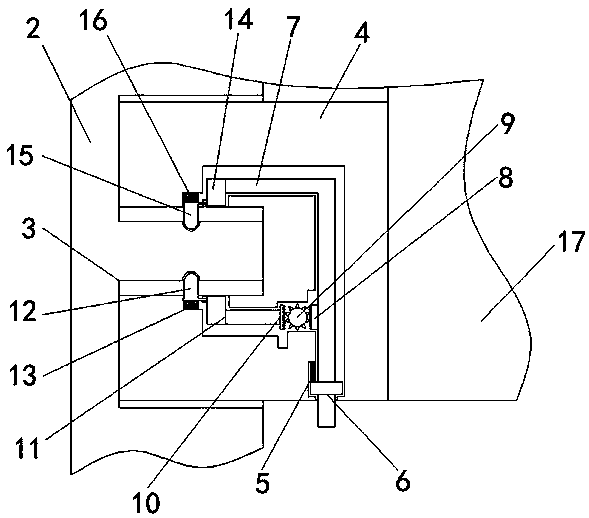

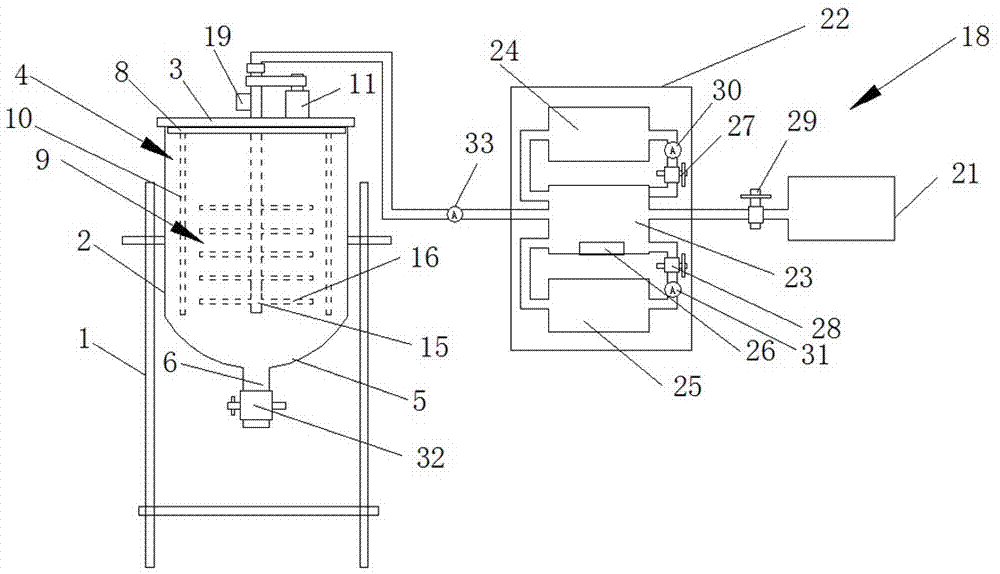

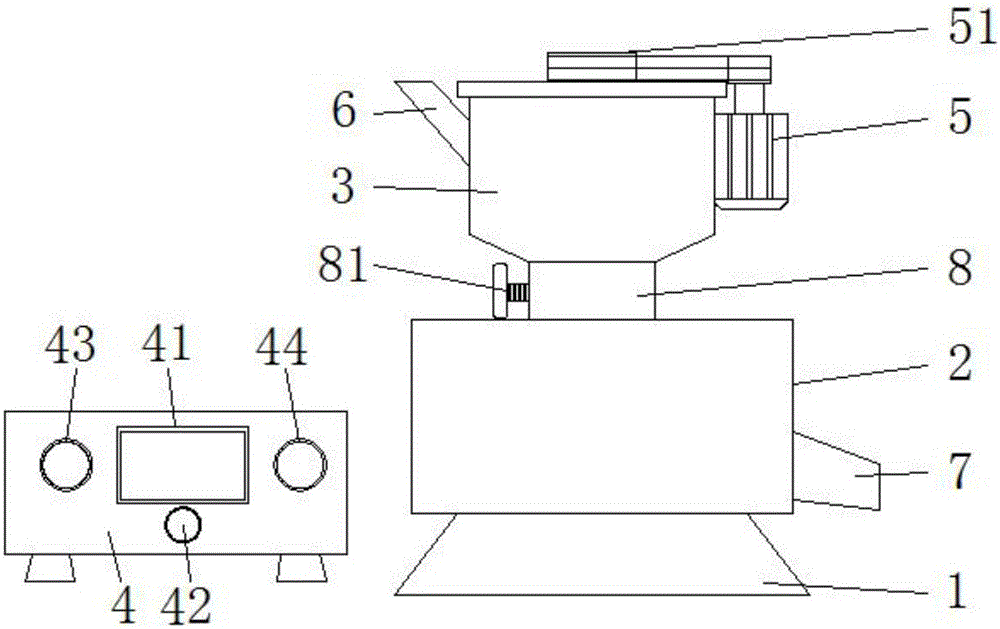

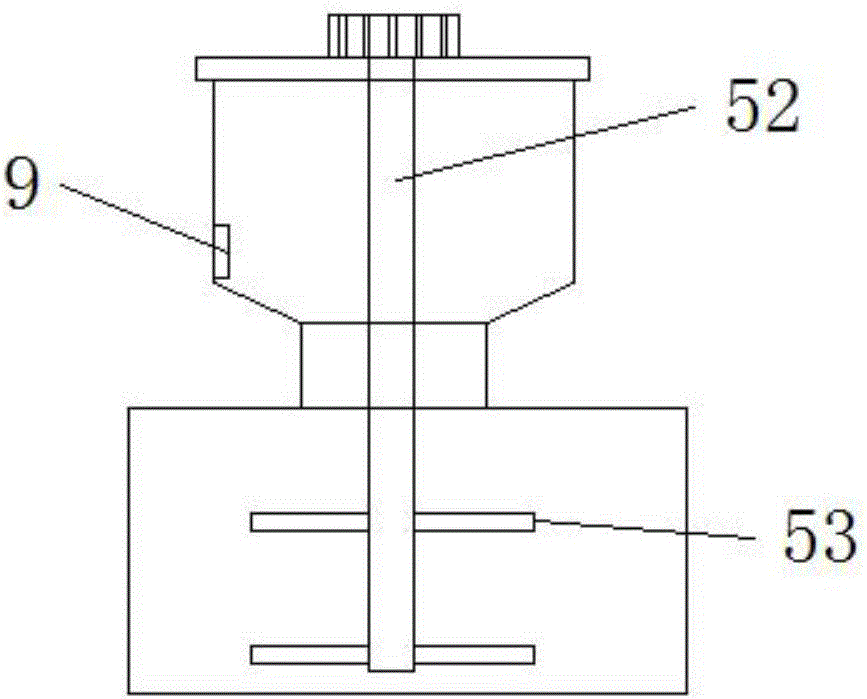

Bionic stirring machine for injection grout, hybrid power bionic stirring system and slurrying method of hybrid power bionic stirring system

ActiveCN107053468AIncrease smoothnessImprove efficiencyMixing operation control apparatusFoundation engineeringProcess engineeringSlurry

The invention discloses a bionic stirring machine for injection grout, a hybrid power bionic stirring system and a slurrying method of the hybrid power bionic stirring system. The bionic stirring machine for injection grout comprises a stirring tank with a feed inlet and a slurry discharge pipe. The bottom face of the stirring tank is an inclined face which is inclined towards the slurry discharge pipe. The upper end of the stirring tank is fixedly provided with a power portion through a supporting frame. The power output end of the power portion is connected with a stirring shaft in the stirring tank. A stirring paddle is vertically or obliquely arranged on the stirring shaft. When the stirring paddle is obliquely arranged on the stirring shaft, the inclination direction of the stirring paddle is opposite to the rotation direction of the stirring shaft. The inner surface of the stirring tank, the inner surface of the feed inlet, the inner surface of the slurry discharge pipe and the stirring paddle are each provided with a plurality of bionic non-smooth units. The superficial area of faces, making contact with the bionic non-smooth units, of the stirring tank, the feed inlet and the slurry discharge pipe is 20-50% of the superficial area of the inner surfaces of the components, and the superficial area of the faces, making contact with the stirring paddle, of all the bionic non-smooth units on the stirring paddle is 20-60% of the superficial area of all surfaces of the stirring paddle.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

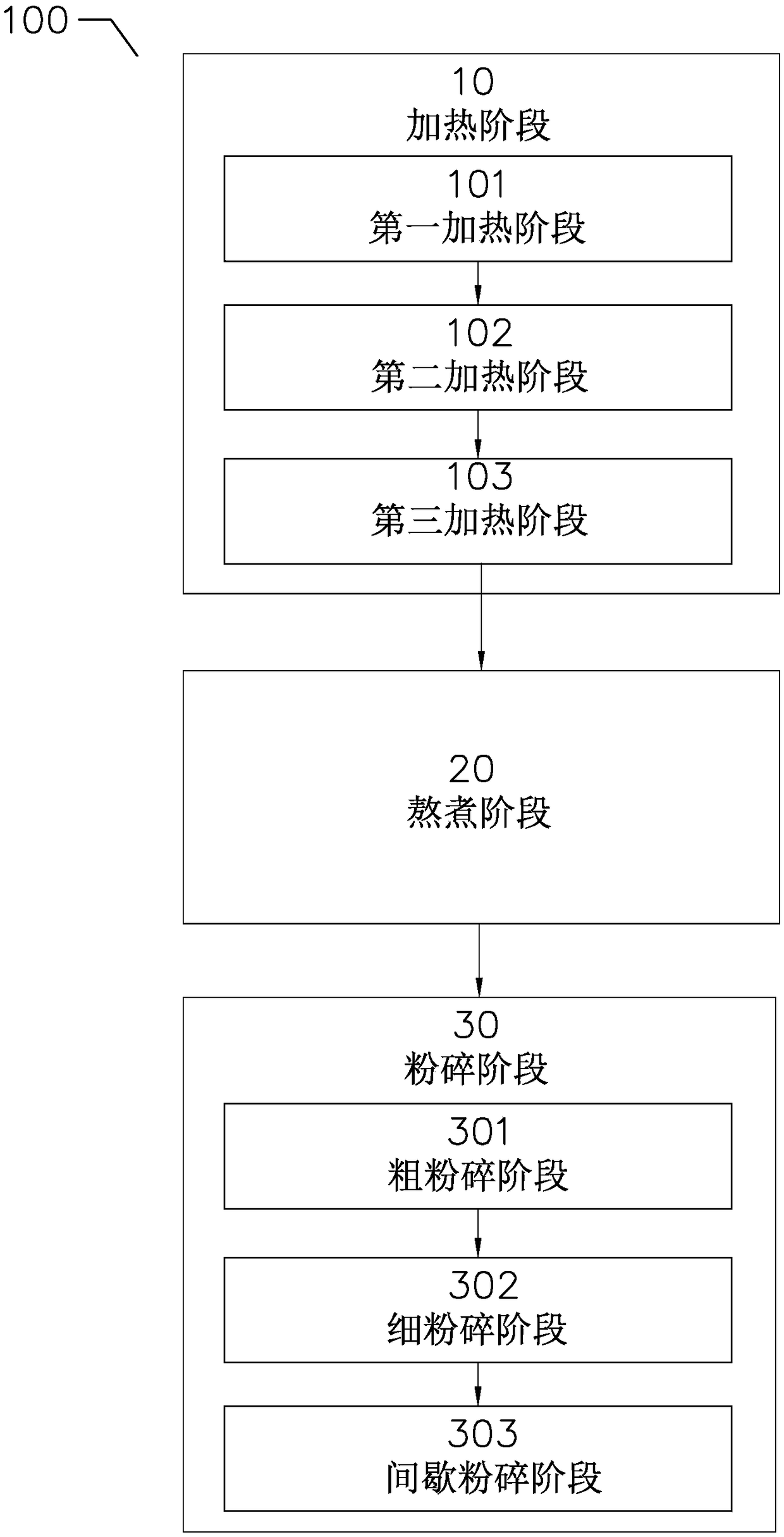

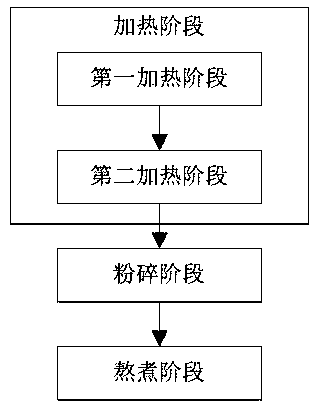

Control method of soybean milk machine

The invention discloses a control method of a soybean milk machine. The soybean milk machine comprises a heating module used for heating materials, a motor module for stirring and smashing the materials and a control device for controlling the heating module and the motor module to work; the soybean milk machine is further provided with a sound detection module, and when the control device controls the motor module to work, the sound pressure value detected by the sound detection module is obtained, and displayed through a display device. The sound pressure value of a sound pressure signal detected in the working period of the soybean milk machine is obtained and displayed, a user effectively acquires the range of noise in time, the acceptance degree of the user to the noise is improved, and the user experience is improved. Since detection display is conducted when the motor module of the soybean milk machine works, the energy is saved, and the consumption is reduced.

Owner:JOYOUNG CO LTD

Organic/inorganic composite coal water mixture additive

InactiveCN104004556ASimple preparation processEasy to operateLiquid carbonaceous fuelsDispersityGlass fiber

The invention provides an organic / inorganic composite coal water mixture additive. The organic / inorganic composite coal water mixture additive is obtained in the mode that sodium carboxymethyl cellulose is intercalated into montmorillonite layers and compounded with glass fiber powder and sulfonate dispersing agents. The organic / inorganic composite coal water mixture additive comprises 10-15% of odium carboxymethyl cellulose intercalation montmorillonite, 1-5% of the glass fiber powder, 35-40% of the sulfonate dispersing agents, an appropriate amount of pH conditioning agents and 45-50% of purified water. By the adoption of the organic / inorganic composite coal water mixture additive, coal water mixtures is prepared, and stripping of the montmorillonite is achieved simultaneously; the interaction between sodium carboxymethyl cellulose molecules is reduced, and the use efficiency and stabilization effect of the organic / inorganic composite coal water mixture additive are improved; meanwhile, other components have collaborative effects of preventing aggregation of coal particles, improving the stability of the coal water mixtures and improving the thixotropic properties of the coal water mixtures; the organic / inorganic composite coal water mixture additive has the advantages that the additive is applicable to various types of coal, mixture forming is easy, and the dispersity, stability and theological properties of coal slurry are excellent.

Owner:江苏合义化工新材料有限公司

Environment-friendly energy-saving straw pulping machine

InactiveCN108660840AImplement collision cuttingAchieve reusePulp liquor regenerationTreatment involving filtrationWater resourcesEconomic benefits

The invention relates to an environment-friendly energy-saving straw pulping machine. The environment-friendly energy-saving straw pulping machine comprises a base, wherein the top of the base is fixedly connected with a circulating water tank, a first filter net and a second filter net are arranged in the circulating water tank in sequence from top to bottom, an inner interlayer of the second filter net is provided with an active carbon bag, the top of the circulating water tank is provided with a pulping machine, the top of the pulping machine is provided with a straw cleaning machine, the top of the straw cleaning machine is provided with a first material feed bin, the left side of the first material feed bin is provided with a first water pump, the first water pump is arranged at the top of the straw cleaning machine, two ends of the first water pump are respectively connected with the straw cleaning machine and the circulating water tank through water tubes, the left side of the straw cleaning machine is provided with a drying oven, and the inner wall of the drying oven is internally provided with an electric heat wire. The environment-friendly energy-saving straw pulping machine can realize multiple production processes of clean, dry, smash and pulp the straw; and the whole structure realizes recycling of the water resource and saves water, so that the pumping machine ismore environmentally friendly and energy-saving, lowers production cost, and improves economic benefits.

Owner:徐佩

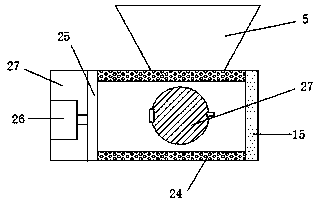

Loquat pulp-beating machine convenient to disassemble

The invention relates to the technical field of loquat processing, and discloses a loquat pulp-beating machine convenient to disassemble. The loquat pulp-beating machine convenient to disassemble comprises an installation base; a fixed ring is fixedly connected with a right side of the installation base; a first groove is formed in a right side of the fixed ring; a fixing block is movably connected in the first groove; a first spring is fixedly connected in the fixing block; a button is fixedly connected with a bottom of the first spring; a connecting rod is fixedly connected with a top of thebutton; a first toothed block is fixedly connected with a left side of the connecting rod; a gear is meshed with a left side of the first toothed block, and is in rotating connection in the fixing block; a second toothed block is meshed with a left side of the gear; a connecting block is fixedly connected with a left side of the second toothed block; and a first clamping block is fixedly connected with a left side of the connecting block. The loquat pulp-beating machine convenient to disassemble achieves the purposes of convenient disassembly and easy pulp discharge.

Owner:黄忠南

Pulping method of food processor

Owner:JOYOUNG CO LTD

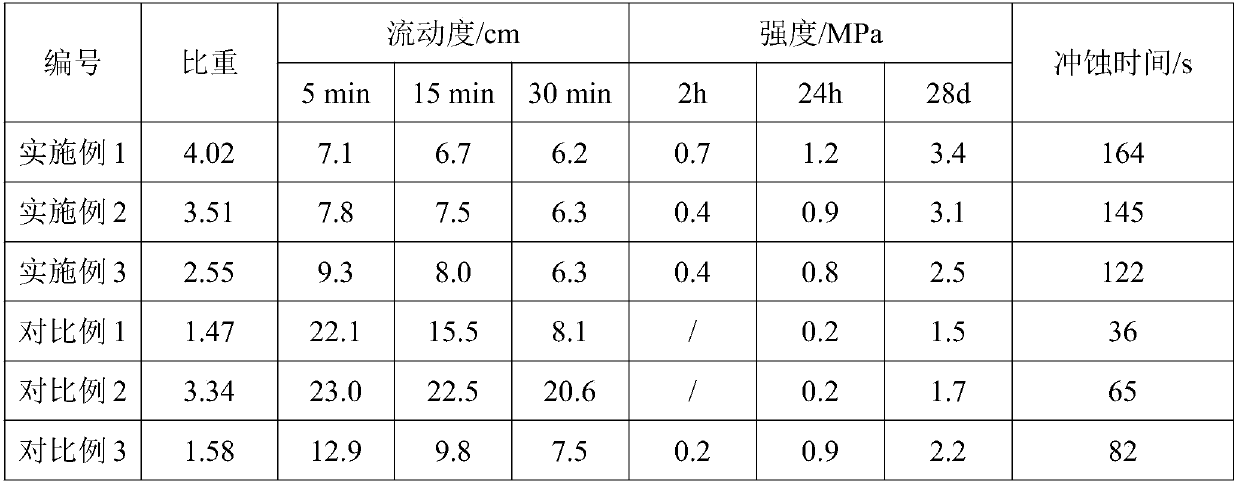

Anti-seepage and reinforcing paste slurry capable of resisting water flow erosion

Anti-seepage and reinforcing paste slurry capable of resisting water flow erosion comprises a clay powder, cement and water, and also comprises a thickening agent, a weight-increasing agent and a tackifier, wherein the thickening agent is water-absorbing resin; the weight-increasing agent is a mixture of at least one of barite powder and iron ore powder and steel sand; the tackifier is vegetable gelatin. The paste slurry has low initial consistence and large specific gravity, avoids separation and layering, has high viscosity and high flowing water erosion resistance, is simple and convenientto slurry, low in cost and easy to operate, and has a wide market prospect.

Owner:湖南宏禹工程集团有限公司

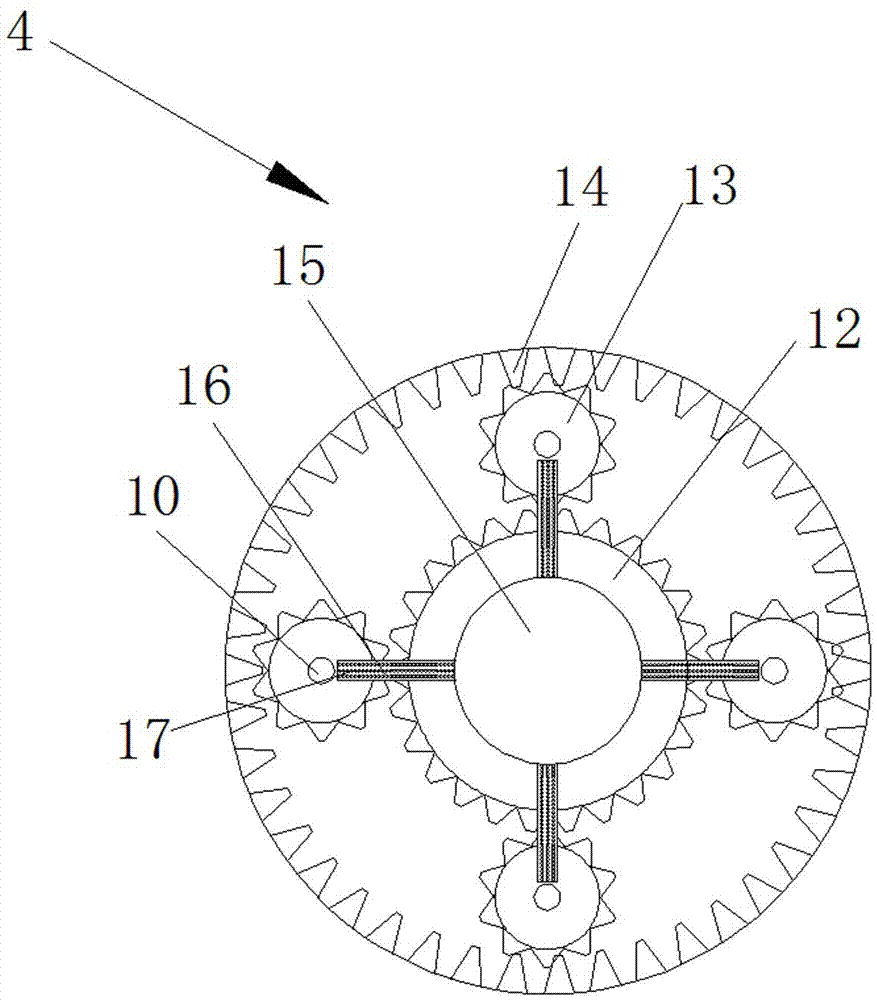

Syrup heating device

The invention relates to a syrup heating device, comprising a frame, a heating barrel, an upper cover and a stirring mechanism; the heating barrel is fixedly connected with the frame, and the bottom of the heating barrel is a concave arc surface, and the concave arc surface There is a slurry outlet in the center of the center; the upper cover is detachably connected with the heating barrel, and the stirring mechanism is arranged under the upper cover; the stirring mechanism includes a planetary gear mechanism, a central stirring member, an auxiliary stirring rod and a stirring motor; the stirring The motor is arranged on the upper end surface of the upper cover, and the central stirring member includes a vertically arranged hollow central rod and several hollow support rods vertically arranged on the central rod; There are a plurality of through holes; one end of the central rod is sealed, and the other end communicates with an outlet pipe of a steam mechanism; the sun gear of the planetary gear mechanism is fixedly sleeved on the central rod, and the upper end of the central rod is provided with a torque sensor, so The torque sensor is communicated with a controller.

Owner:刘光跃

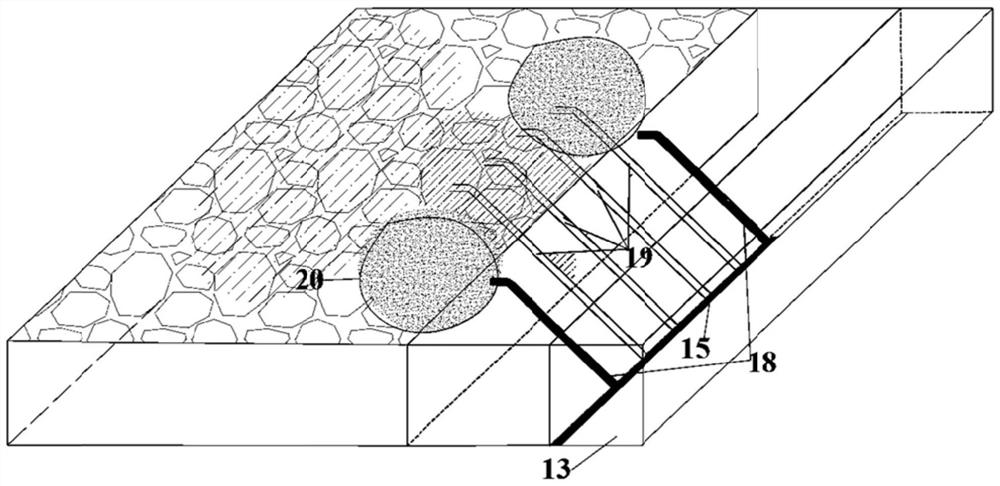

Sectional cementing grouting filling method for coal mine caving area

PendingCN114837737APrevent backflowSolve disasters such as wind leakageMaterial fill-upMining engineeringSlurry

The invention relates to the technical field of coal mine filling mining, is suitable for a fluidization filling working face of a gangue caving area, and particularly relates to a coal mine caving area segmental cementation grouting filling method which comprises the following steps: constructing a plurality of cementation grouting filling holes and original gangue grouting filling holes in an isolation coal pillar of a goaf of a stope working face; wherein the original gangue grouting filling holes are used for treating gangue normally in a large scale, orifices on one sides, close to the goaf of the stope face, of the plurality of cementation grouting filling holes are correspondingly connected with the flexible film bags, cementation grouting is carried out through the cementation grouting filling holes, and a cementation retaining wall is formed after the flexible film bags are solidified. The caving gangue in the caving area behind the cemented retaining wall also forms a closed isolation area section, the isolation area section and the cemented retaining wall form an isolation wall, filling slurry is prevented from flowing back to the goaf, the problem of disasters such as air leakage of the goaf is solved, and the method is easy and convenient to operate and low in cost and has wide application and popularization prospects.

Owner:渭南陕煤启辰科技有限公司

Pulping method of soymilk maker

ActiveCN107821609AAlmost temperatureUniform temperatureMilk substitutesFood scienceEngineeringTime-Consuming

Owner:HONGYANG HOME APPLIANCES

Method for preparing ecological active residues by treating electrolytic manganese residues by using tunnel kiln device

The invention relates to a method for preparing ecological active residues by treating electrolytic manganese residues by using a tunnel kiln device. The method comprises the following steps: (1) blending and homogenizing: blending 45-75 parts of electrolytic manganese residues, 8-25 parts of stone coal, 14.7-45.0 parts of waste rock residues and 0.3-2.0 parts of an alteration agent, grinding the mixture into powder, adding 5-15 parts of water, and uniformly and homogenizing the mixture to a plastified material; (2) molding: molding the plastified material to a rod-like or bulk-like molded material; and (3) calcining the tunnel kiln: sending the molded material in the tunnel kiln, calcining the molded material for 20-60 minutes at 980-1300 DEG C, and quenching the molded material to obtain the ecological active residues. The ecological active residues contain various hydrated active minerals, can be widely used for cement industry, is high in strength if being used, and is easy to slurry and high in strength if being used as masonry cement or cement making bricks. The method provided by the invention is low in investment, free of wastewater and waste residues and good in economical benefit.

Owner:湖南省小尹无忌环境能源科技开发有限公司

Method for pulping by broussonetia papyrifera white-bark

ActiveCN103498375AReduce pollutionQuick responseFats/resins/pitch/waxes removal in pulpPulp bleachingEthylene diaminePollution

The invention discloses a method for pulping by broussonetia papyrifera white-bark which is a novel raw material selectively bred in recent years through microwave radiation. The method comprises the following steps: adopting,, and carrying out microwave radiation on an adopted bast fiber raw material, namely broussonetia papyrifera white-bark at normal pressure by using H2SO3, CH3COOOH, NaOH, H2O2, Na2P2O7 and an EDTA (Ethylene Diamine Tetraacetic Acid) additive to prepare pulp. According to the method, a by-product, namely pectin with high value can be extracted in the pulping process. The prepared broussonetia papyrifera white-bark long-fibered pulp has the characteristics of high virgin pulp yield and high whiteness. The method synchronizes digesting and bleaching, the pulping process can be carried out at normal pressure, the time is short, and the pollution is slight.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT

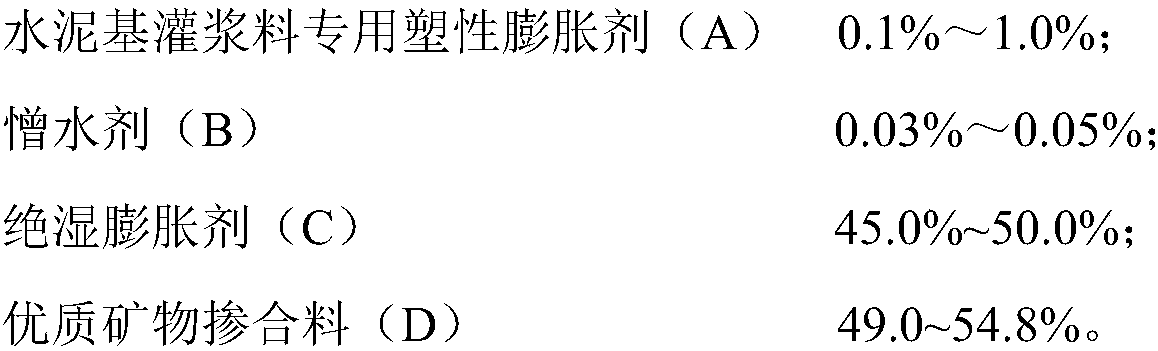

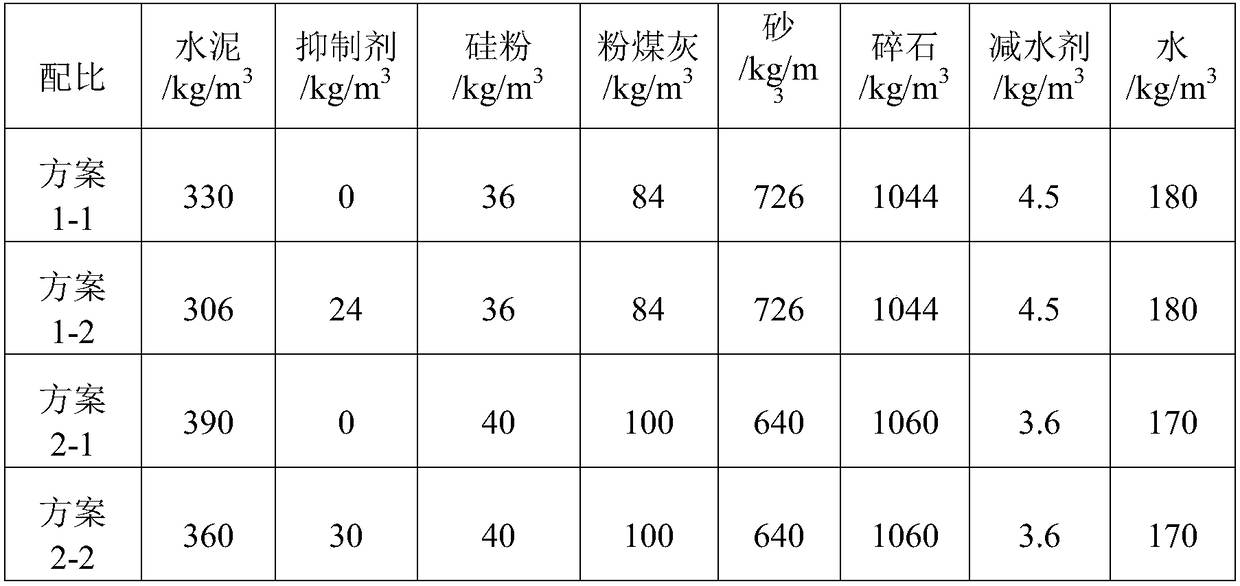

Water-conservancy-project high-water-head tunnel spillway bottom plate concrete crack defect inhibitor and preparation method thereof

The invention discloses a water-conservancy-project high-water-head tunnel spillway bottom plate concrete crack defect inhibitor and a preparation method thereof. The inhibitor comprises, by weight percentage, 0.0-1.0% of plastic expanding agent special for cement-based grouting material, 0.03-0.05% of water repellent, 45.0-50.0% of waterproof expanding agent, 49.0-54.8% of high-quality mineral admixture. The inhibitor is prepared by evenly mixing the materials above in a high-speed stirrer. The prepared inhibitor is capable of effectively preventing concrete plastic settling micro-crack defects, capable of blocking capillary pore channels, capable of increasing the early tensile stress of concrete, capable of improving the structural compactness, uniformity and surface smoothness of the concrete, capable of reducing crack defects caused by uneven temperature stress and surface impact and abrasion, capable of increasing the impact and abrasion resisting strength of the water-conservancy-project high-water-head tunnel spillway bottom plate concrete by 50%, and capable of reducing surface cracks and penetrating cracks by more than 70%.

Owner:NANJING HYDRAULIC RES INST

Control method for food processor

The invention provides a controlling method for a food processor. The food processor comprises a motor which is a brushless electric machine, the brushless electric machine is provided with a smashingcutter blade, and in the pulping process, the food processor smashes materials in two stages, namely the initial smashing stage and the smashing stage. In the initial smashing stage, the revolving speed M of the brushless electric machine is smaller than 8000 revolutions / minute, forward rotation and reverse rotation of the brushless electric machine are continuously alternately conducted, and thepreset waiting time duration T between the forward rotation and the reverse rotation is longer than 0.5 second and shorter than 10 seconds. In the control method, through the work mode that restrictive forward-reverse rotation of the motor is conducted through initial smashing, noise can be effectively reduced, the smashing time can be greatly shortened, and the smashing efficiency is improved.

Owner:JOYOUNG CO LTD

A kind of organic/inorganic composite coal water slurry additive

InactiveCN104004556BSimple preparation processEasy to operateLiquid carbonaceous fuelsDispersityCoal water

The invention provides an organic / inorganic composite coal water mixture additive. The organic / inorganic composite coal water mixture additive is obtained in the mode that sodium carboxymethyl cellulose is intercalated into montmorillonite layers and compounded with glass fiber powder and sulfonate dispersing agents. The organic / inorganic composite coal water mixture additive comprises 10-15% of odium carboxymethyl cellulose intercalation montmorillonite, 1-5% of the glass fiber powder, 35-40% of the sulfonate dispersing agents, an appropriate amount of pH conditioning agents and 45-50% of purified water. By the adoption of the organic / inorganic composite coal water mixture additive, coal water mixtures is prepared, and stripping of the montmorillonite is achieved simultaneously; the interaction between sodium carboxymethyl cellulose molecules is reduced, and the use efficiency and stabilization effect of the organic / inorganic composite coal water mixture additive are improved; meanwhile, other components have collaborative effects of preventing aggregation of coal particles, improving the stability of the coal water mixtures and improving the thixotropic properties of the coal water mixtures; the organic / inorganic composite coal water mixture additive has the advantages that the additive is applicable to various types of coal, mixture forming is easy, and the dispersity, stability and theological properties of coal slurry are excellent.

Owner:江苏合义化工新材料有限公司

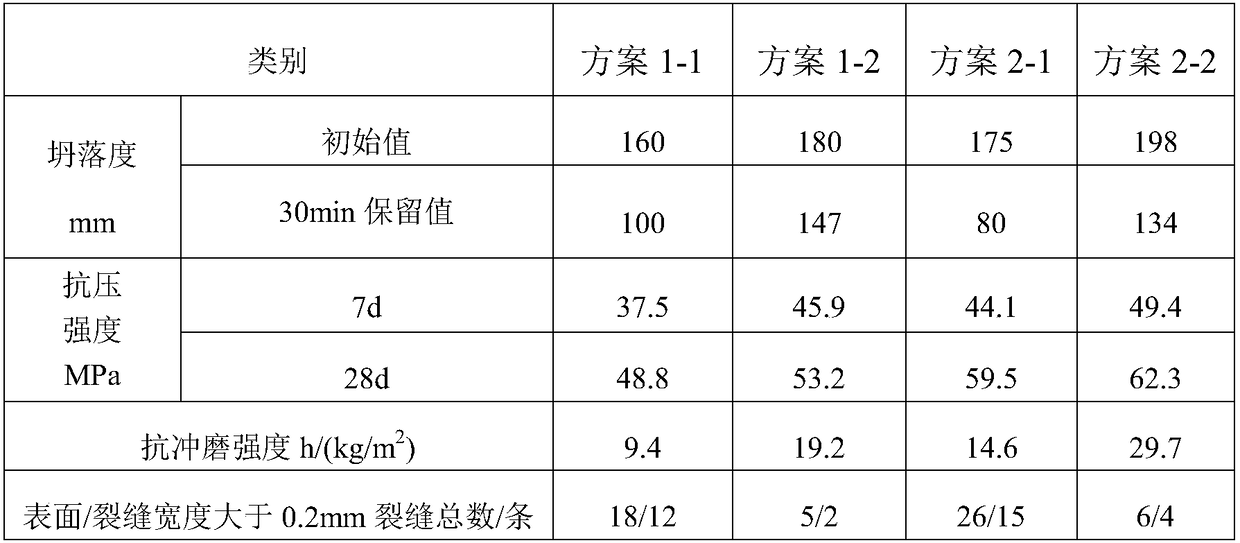

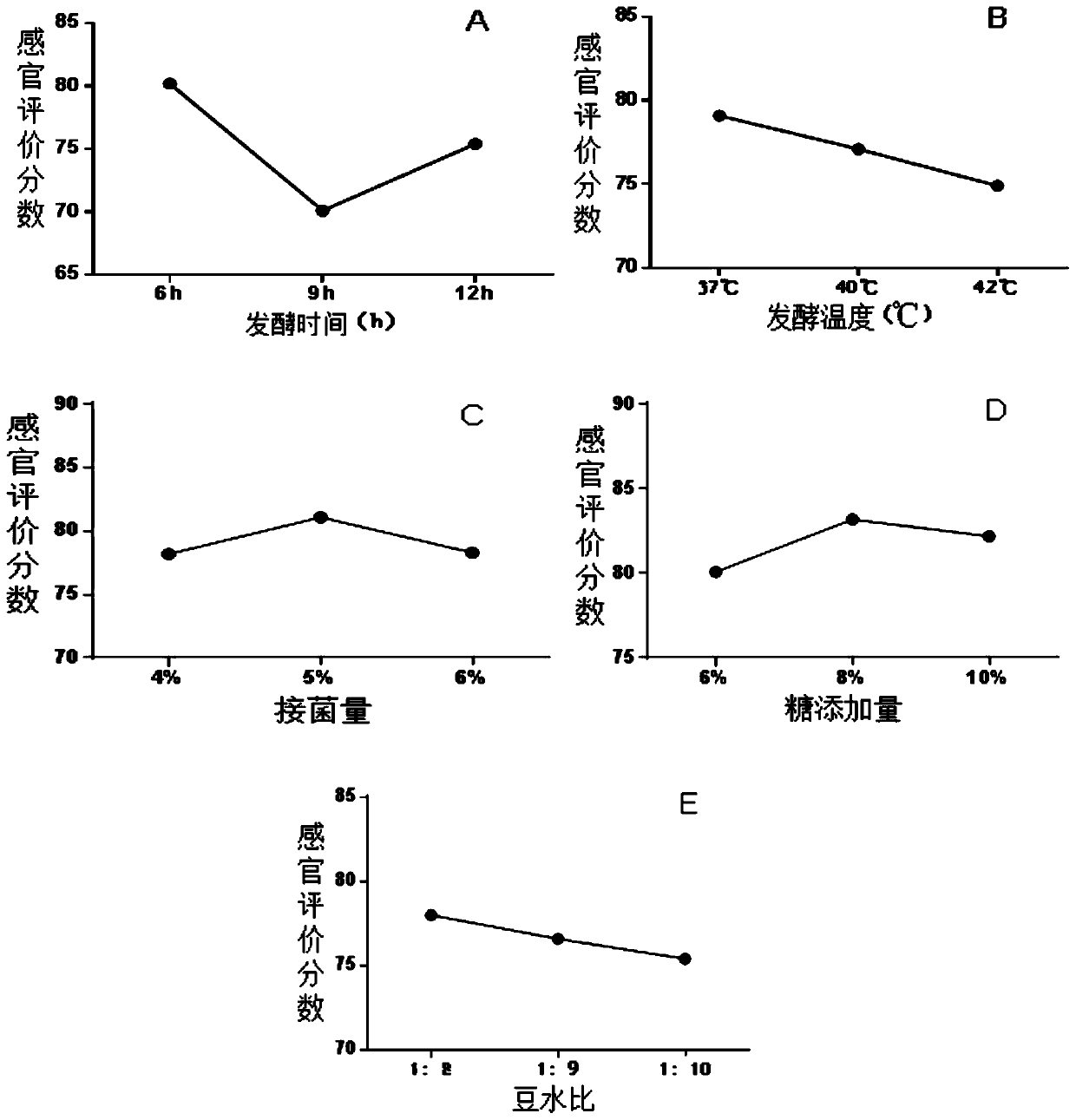

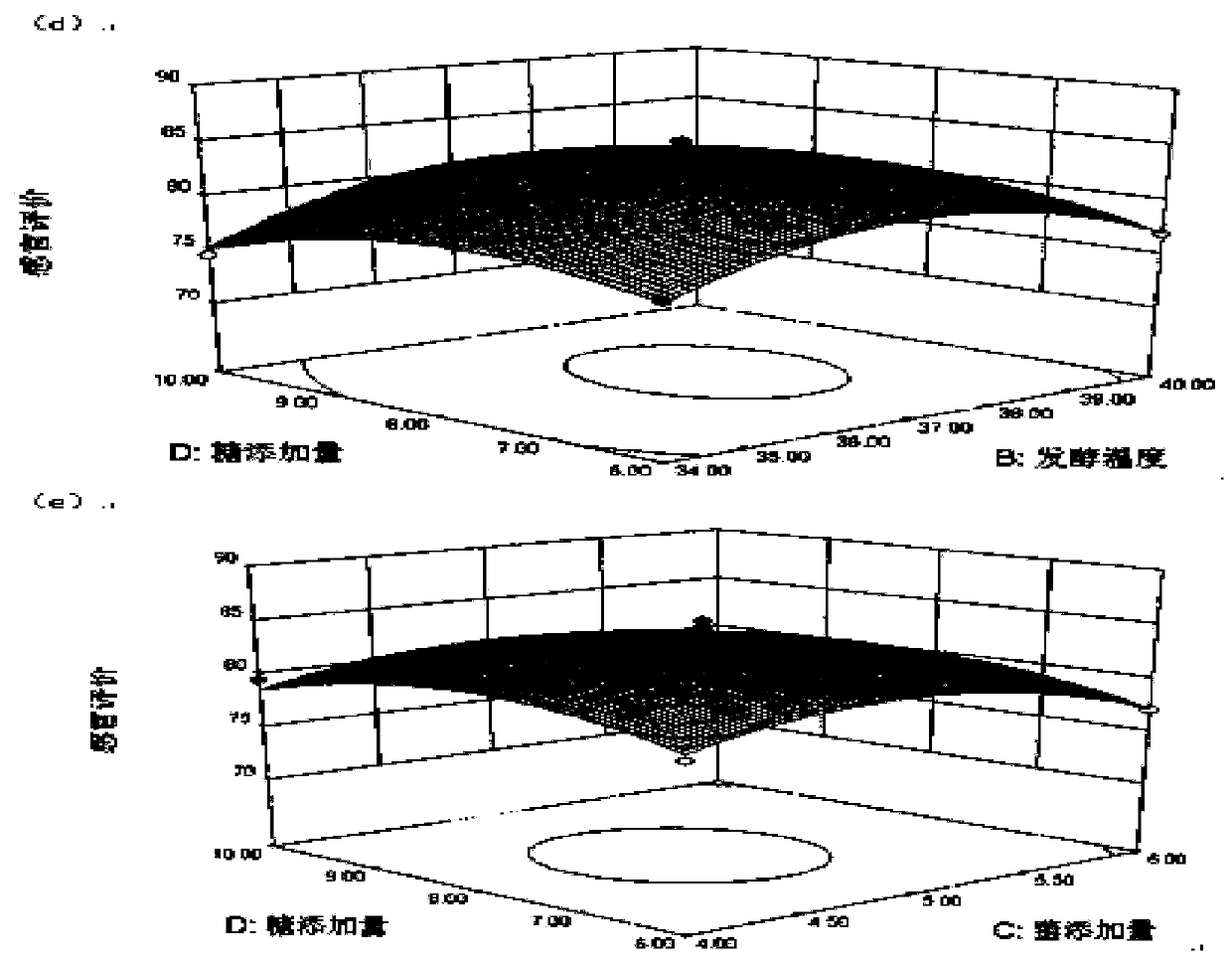

Preparation method of lipid-lowering compound probiotics fermented sour soybean milk

The invention discloses a preparation method of lipid-lowering compound probiotics fermented sour soybean milk. The preparation method includes the steps of S1, selecting raw materials; S2, soaking the raw materials; S3, crushing the raw materials to prepare pulp; S4, inoculating bacterial colonies; S5, preparing the lipid-lowering compound probiotics fermented sour soybean milk. The preparationmethod has the advantages that due to the fact that soybeans are unpeeled, sufficient raw material utilization is achieved while the unpeeled soybeans have high anti-oxidation ability and more dietaryfibers and isoflavones; lactobacillus plantarum and Lactobacillus paracasei are used as the fermentation bacterial colonies, aerobic reproduction is performed during fermentation, anaerobic fermentation is performed, and accordingly lactobacillin and Lactobacillus paracasei bacillin are generated sufficiently, and product shelf life is prolonged while human immunity and digestive ability are increased; by using Design-Expert 8.0 software to perform response surface optimization design to detect flavor and using blood, liver and excrement indexes detected by animal experiments to perform lipidlowering detection, the taste and lipid-lowering effect of the fermented sour soybean milk are scientifically detected.

Owner:JILIN AGRICULTURAL UNIV

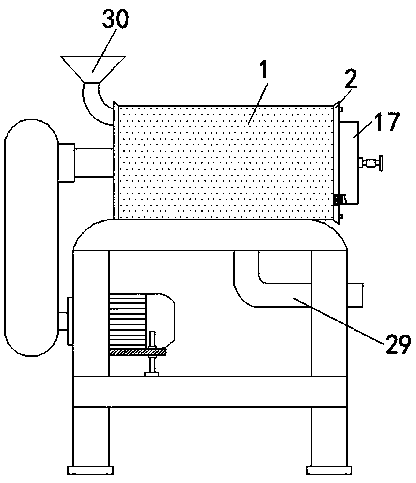

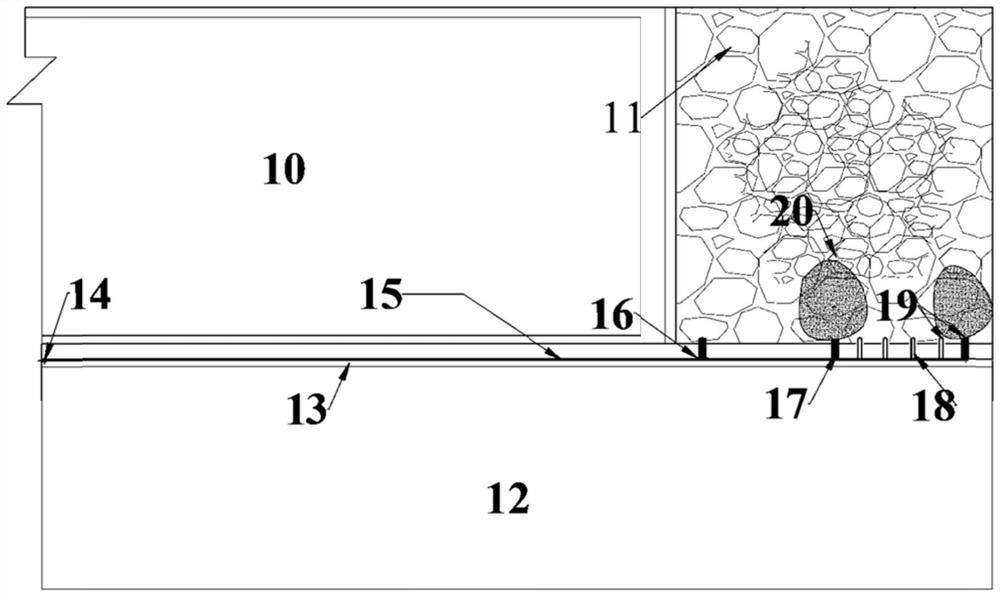

Soaking-free pulping machine and control method thereof

InactiveCN106368029AAchieve smashEasy to pulpRaw material divisionAutomatic controlTemperature sense

The invention discloses a soaking-free pulping machine and a control method thereof. The soaking-free pulping machine comprises a supporting base, a container, a containing hopper, a stirring system and a control system, wherein the container which appears cylindrical is arranged on the upper portion of the supporting base, an inclined discharging port is formed in the position, close to the lower end, of the right side of the container, and the containing hopper is arranged at the top of the container; a feeding port is formed in the position, close to the upper end, of the left side of the containing hopper, and a temperature sensing probe is arranged on the inner wall of the containing hopper; the stirring system is arranged at the top center of the containing hopper, and comprises a low-speed motor, a straight gear, a stirring shaft and pulverizing blades; the control system is arranged on the left side of the container, and comprises a heating device, a control panel, and a display, a speed regulation rotary knob, a thermometer and a time display panel which are arranged on the control panel. According to the soaking-free pulping machine, the paper making raw materials are mixed through an automatic control system, on one hand, pulping is facilitated, on the other hand, it is avoided that a traditional soaking pulping technology is adopted, and the working efficiency of the device is improved.

Owner:WEIFANG UNIV OF SCI & TECH

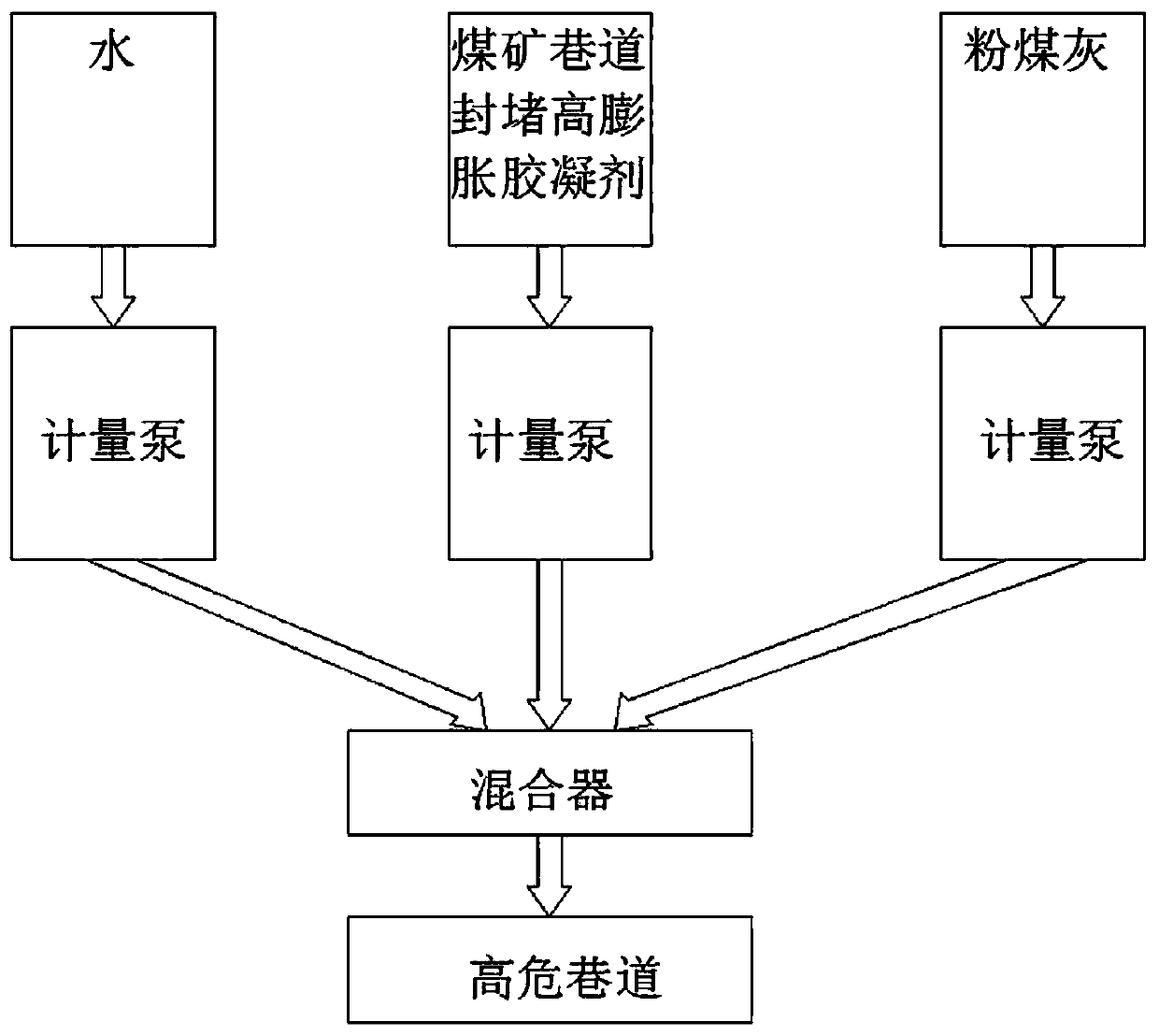

High-expansion gelling agent for plugging coal mine tunnel

The invention discloses a high-expansion gelling agent for plugging a coal mine tunnel. The high-expansion gelling agent for plugging the coal mine tunnel comprises 40-50 wt% of calcium chloride, 20-30 wt% of calcium sulphoaluminate, 20-30 wt% of calcium aluminate, 0.2-0.5 wt% of spherical aluminum powder and 0.5-1 wt% of redispersible latex powder. The process is simple and advanced. The high-expansion gelling agent for plugging the coal mine tunnel only needs to be uniformly mixed with water and fly ash according to a certain ratio when used, the obtained mixture is conveyed to the filling area of a goaf, and devices used for underground filling are simple, and have a small quantity, a high efficiency and a high production capability. A slurry coagulates and fills without dehydrating, and the filled body has a good supporting performance; and the slurry can be prepared in a bottom surface intensive pulping manner or an underground onsite pulping manner, and the slurry has a good suspension property, and can be regarded as a homogeneous slurry during transportation, so pulping and conveying are convenient, and the slurry conveying quality can be guaranteed.

Owner:焦作市中砼科技有限公司

Method for producing ecologically active slag by treating electrolytic manganese slag with tunnel kiln equipment

Owner:湖南省小尹无忌环境能源科技开发有限公司

A method for preparing low-density ceramsite proppant using high-alumina fly ash as raw material

ActiveCN105524607BAvoid the disadvantages of poor liquidityEasy to pulpFluid removalDrilling compositionExpanded clay aggregateEngineering

The invention discloses a method for preparing a low-density ceramsite proppant from high-alumina fly ash. The method comprises the steps: (1) proportioning raw high-alumina fly ash, burnt high-alumina fly ash, clay, dolomite, talcum, river sand and an additive, and then, carrying out uniform mixing; adding water into the mixture, and carrying out wet grinding, so as to prepare mud; and then, drying the mud to prepare a powder material, and then, carrying out crushing, so as to prepare micropowder; (2) additionally, carrying out dry-process ball-milling or airflow crushing on raw high-alumina fly ash, so as to obtain micropowder with grain size smaller than 200 meshes; and (3) uniformly mixing the micropowder obtained in the step (1) and the micropowder obtained in the step (2), discontinuously spraying an aqueous solution containing the additive into the mixture, and carrying out granulating, so as to prepare sphere blanks; and then, carrying out polishing, semifinished product screening, baking, calcining and finished product screening, thereby obtaining a finished product. According to the method, the usage amount of the fly ash can reach 90%, the fly ash replaces other aluminiferous silicon raw materials such as bauxite, and the waste is utilized, so that the resource consumption is lowered; and the obtained fly ash proppant product is excellent in performance and stable in quality.

Owner:JINGANG NEW MATERIALS

Crushing equipment for corrugated paper recycling

ActiveCN111778751AAchieve extrusionAchieve brokenPaper recyclingRaw material divisionPaper recyclingElectric machinery

The invention relates to a crushing equipment for corrugated paper recycling. The crushing equipment comprises a crushing barrel, a telescopic mechanism, a motor and a crushing disc, the crushing barrel is obliquely arranged, the crushing barrel is provided with a cylindrical inner cavity with an opening in the upper end and a closed lower end, and a discharging opening b is formed in the barrel bottom of the crushing barrel; the crushing disc is arranged in the inner cavity, and a feeding port is formed in the area, between the crushing disc and the bottom of the inner cavity, of the wall face of the crushing barrel. An output shaft of the motor is connected with the crushing disc; the telescopic mechanism is connected with the motor and drives the motor and the crushing disc to move in the inner cavity, so that the crushing disc gets close to and away from the bottom of the inner cavity, and crushing teeth are arranged on the end face, close to the bottom of the inner cavity, of thecrushing disc. The invention has the beneficial effects that the whole crushing process is high in efficiency, crushing and pulping can be organically combined, and processing procedures are reduced.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com