Crushing equipment for corrugated paper recycling

A technology for crushing equipment and corrugated paper, applied in the field of corrugated paper recycling, which can solve the problems of easy injury and low efficiency of crushing operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

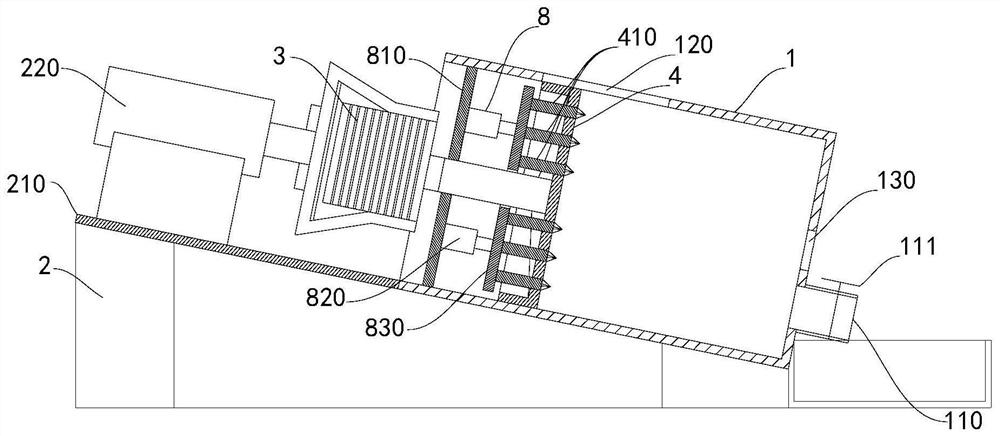

[0018] Example 1, such as figure 1 As shown, a crushing equipment for recycling corrugated paper includes a crushing barrel 1, a telescopic mechanism 2, a motor 3 and a crushing disc 4. The crushing barrel 1 is arranged obliquely. The crushing barrel 1 has a cylindrical inner cavity with an open upper end and a closed lower end. The crushing barrel The bottom of the barrel of 1 is provided with discharge port b110; the crushing disc 4 is placed in the inner cavity, and the wall surface of the crushing barrel 1 is provided with a feeding port 120 in the area between the crushing disc 4 and the bottom of the inner cavity; the output shaft of the motor 3 It is connected with the broken disc 4; the telescopic mechanism 2 is connected with the motor 3, and drives the motor 3 and the broken disc 4 to move in the inner cavity, so that the broken disc 4 is close to and away from the bottom of the inner cavity, and the broken disc 4 is close to the inner cavity The end face of the cavi...

Embodiment 2

[0019] Example 2, such as figure 1 As shown, the present embodiment is a further optimization carried out on the basis of embodiment 1, which is specifically as follows:

[0020] The telescoping mechanism 2 includes a base 210 and a hydraulic cylinder 220 , the hydraulic cylinder 220 is arranged on the base 210 , the crushing barrel 1 is arranged on the base 210 obliquely, and the piston rod of the hydraulic cylinder 220 is connected with the motor 3 .

Embodiment 3

[0021] Example 3, such as figure 1 As shown, the present embodiment is a further optimization carried out on the basis of embodiment 1 or 2, which is specifically as follows:

[0022] The crushing equipment for corrugated paper recycling also includes an adjustment mechanism 8, which is arranged on the output shaft of the motor 3 or on the inner wall of the crushing barrel 1, and the crushing disc 4 is provided with a via hole, and one end of the crushing tooth 410 is connected with the adjustment mechanism 8, The other end of the crushing tooth 410 extends to the bottom of the inner cavity through the hole, and is driven by the adjustment mechanism 8 to approach and stay away from the bottom of the inner cavity. A rubber ring is provided in the hole to prevent the slurry from passing through in the later pulping process. The gap between the crushing tooth 410 and the via hole is splashed out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com