Soaking-free pulping machine and control method thereof

A technology that does not require soaking and control methods. It is applied in the direction of raw material separation, etc., and can solve the problems of inability to control the parameters of the pulping process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

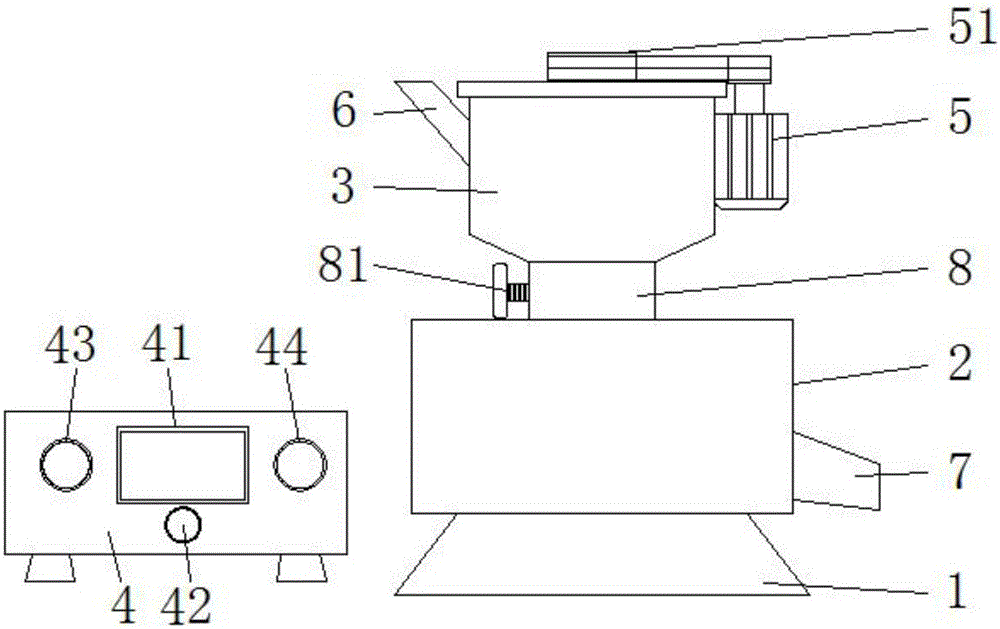

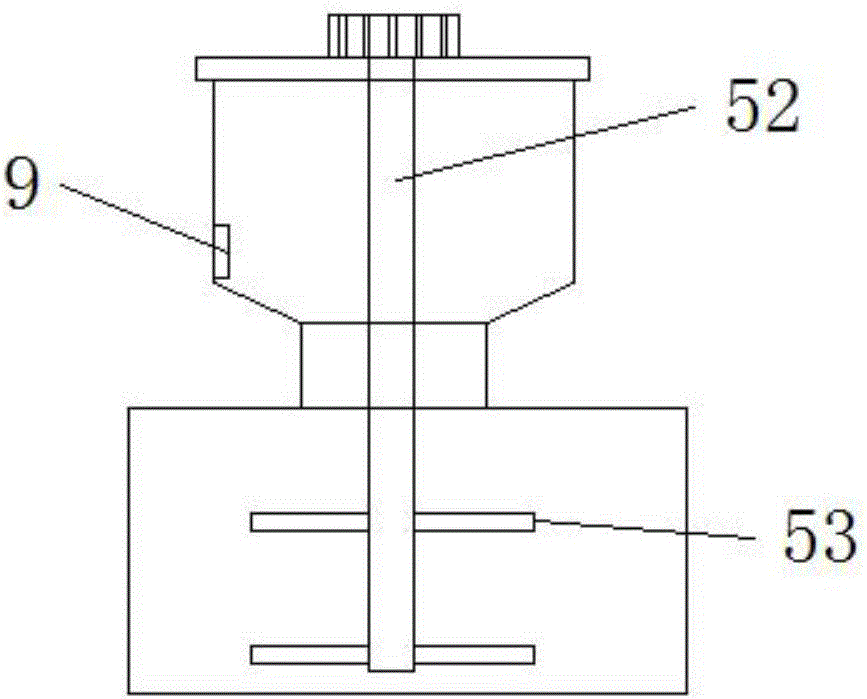

[0016] like Figure 1-2 As shown, the present invention does not require immersion type pulping machine and its control method, including a support base 1, a container 2, a hopper 3, a stirring system and a control system, the upper part of the support base 1 is installed with a cylindrical container 2, the container The right side of 2 is provided with the outlet 7 that is inclined installation near the lower end, and the hopper 3 is installed on the top of the container 2, and the left side of the hopper 3 is provided with the inlet 6 near the upper end, and the inner wall of the hopper 3 is installed A temperature sensing probe 9 is provided, and the stirring system is installed in the middle of the top of the hopper 3, and the stirring system includes a speed regulating motor 5, a spur gear 51, a stirring shaft 52 and a crushing blade 53, and the control system is installed on the left side of the container 2, and the control system The system includes a heating device, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com