Cereal grinding method

A grinding method and grain technology, which is applied in the field of grain grinding, can solve the problems of not being able to meet the needs of a small amount of grinding, product quality cannot be guaranteed, and the rotation of the upper grinding disc is unstable, so as to achieve uniform particle size and product quality assurance , The effect of grinding process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe in detail the technical content, the achieved objectives and effects of the present invention, the following description will be given in conjunction with the embodiments and the accompanying drawings.

[0023] Please refer to figure 1 As shown, the grain grinding method provided by the present invention includes the following steps:

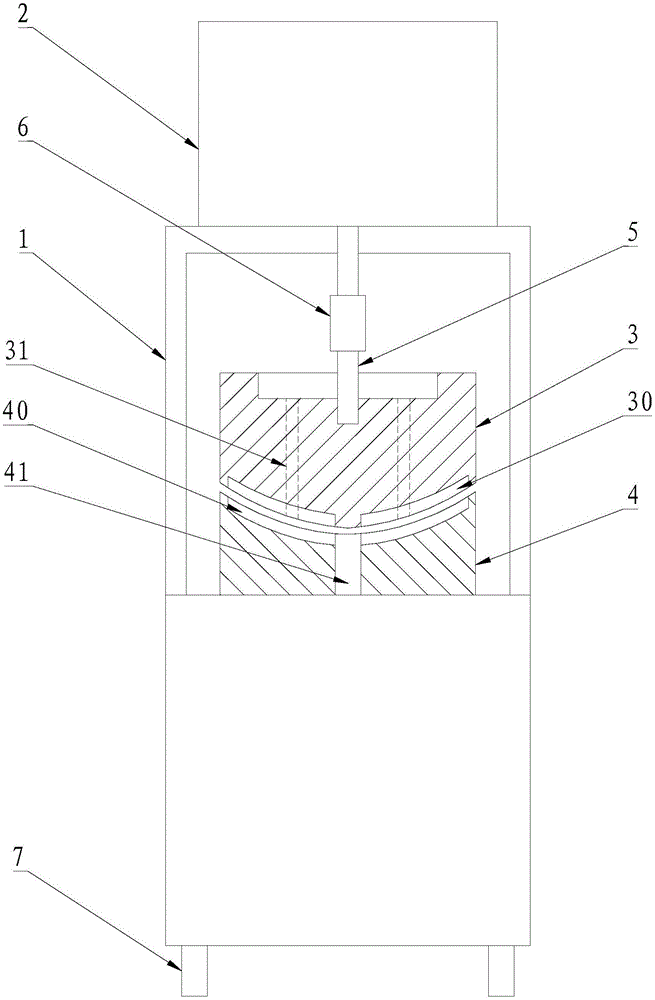

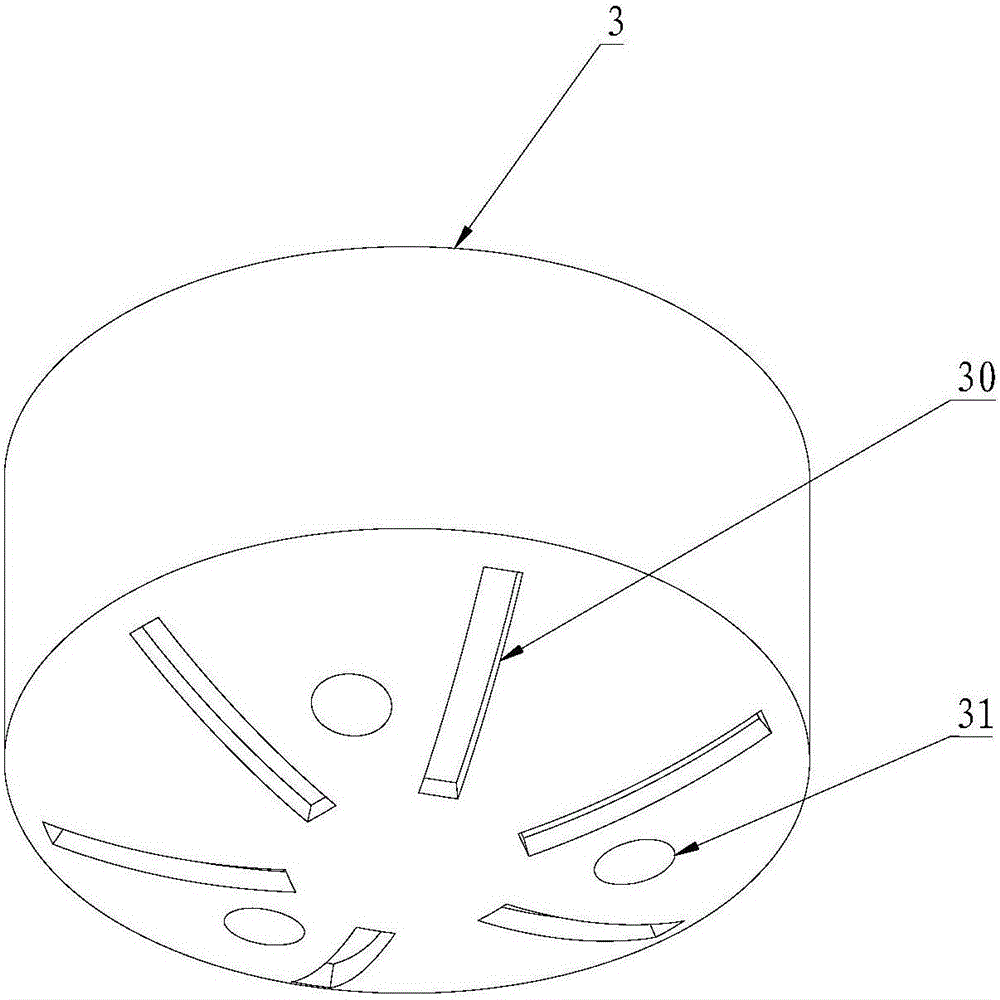

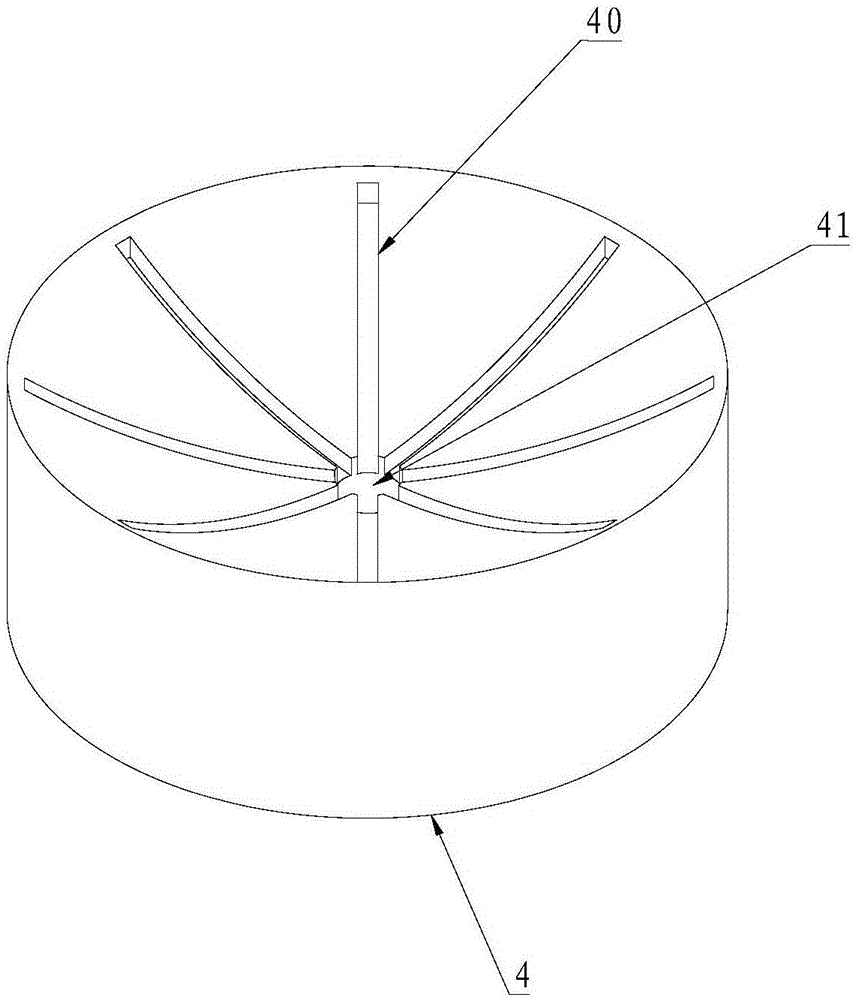

[0024] Step 1. Provide a grain grinder. The grain grinder includes a frame 1, a motor 2 and a grinding disc. The motor 2 and the grinding disc are respectively installed on the frame 1. The grinding disc is composed of an upper grinding disc 3 and a lower grinding disc 4. The motor 2 is located above the grinding disc. The output shaft of the motor 2 is connected to the upper grinding disc 3 and drives the upper grinding disc 3 to rotate. The upper grinding disc 3 and the lower grinding disc 4 have the same diameter, and the lower surface of the upper grinding disc 3 is convex The lower surface of the upper grinding disc 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com