Pulping device of paper shredder

A paper shredder and pulp technology, applied in the direction of grain processing, etc., can solve the problems of inconvenient processing and volume occupied by waste paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

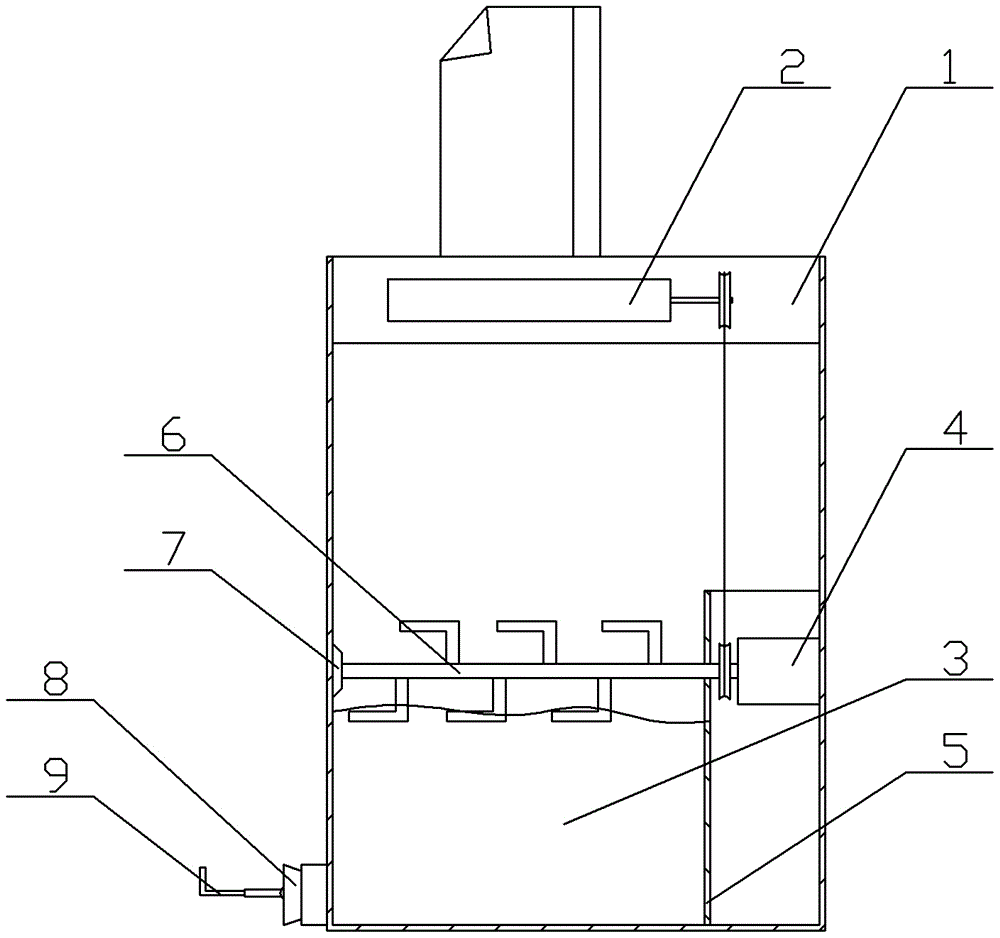

[0012] The reference numerals in the drawings of the description include: housing 1, cutter shaft 2, pulp holding box 3, motor 4, partition 5, stirring and pulverizing paddle 6, positioning seat 7, sealing cover 8, and discharge hook 9.

[0013] The paper shredder beating device of embodiment is as attached figure 1 As shown: it includes a paper shredder housing 1 and a paper shredding knife shaft 2 arranged on the upper part of the housing 1. The housing 1 is preferably fixed at a corner to avoid falling over. The lower part of the housing 1 is a beating area. The beating area includes a pulp storage box 3 below the cutter shaft 2 and a motor 4 installed next to the pulp storage box 3. The motor 4 is separated from the pulp storage box 3 through a partition 5. The motor 4 is horizontally arranged, and its output shaft end The part is directly connected to the stirring a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com