High-expansion gelling agent for plugging coal mine tunnel

A coal mine roadway, high-expansion technology, applied in the field of high-expansion gelling agent for coal mine roadway sealing, can solve the problems of complex and cumbersome construction process, and achieve the effect of simple equipment, good support performance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The weight percentage of the ingredients is: calcium chloride 45Kg, calcium sulfoaluminate 30Kg, calcium aluminate 24Kg, spherical aluminum powder 0.5Kg, redispersible latex powder 0.5Kg.

Embodiment 2

[0022] The weight percentage of the ingredients is: calcium chloride 40Kg, calcium sulfoaluminate 30Kg, calcium aluminate 28.5Kg, spherical aluminum powder 0.5Kg, redispersible latex powder 1Kg.

Embodiment 3

[0024] The weight percentage of the ingredients is: calcium chloride 45Kg, calcium sulfoaluminate 25Kg, calcium aluminate 28.8Kg, spherical aluminum powder 0.2Kg, redispersible latex powder 1Kg.

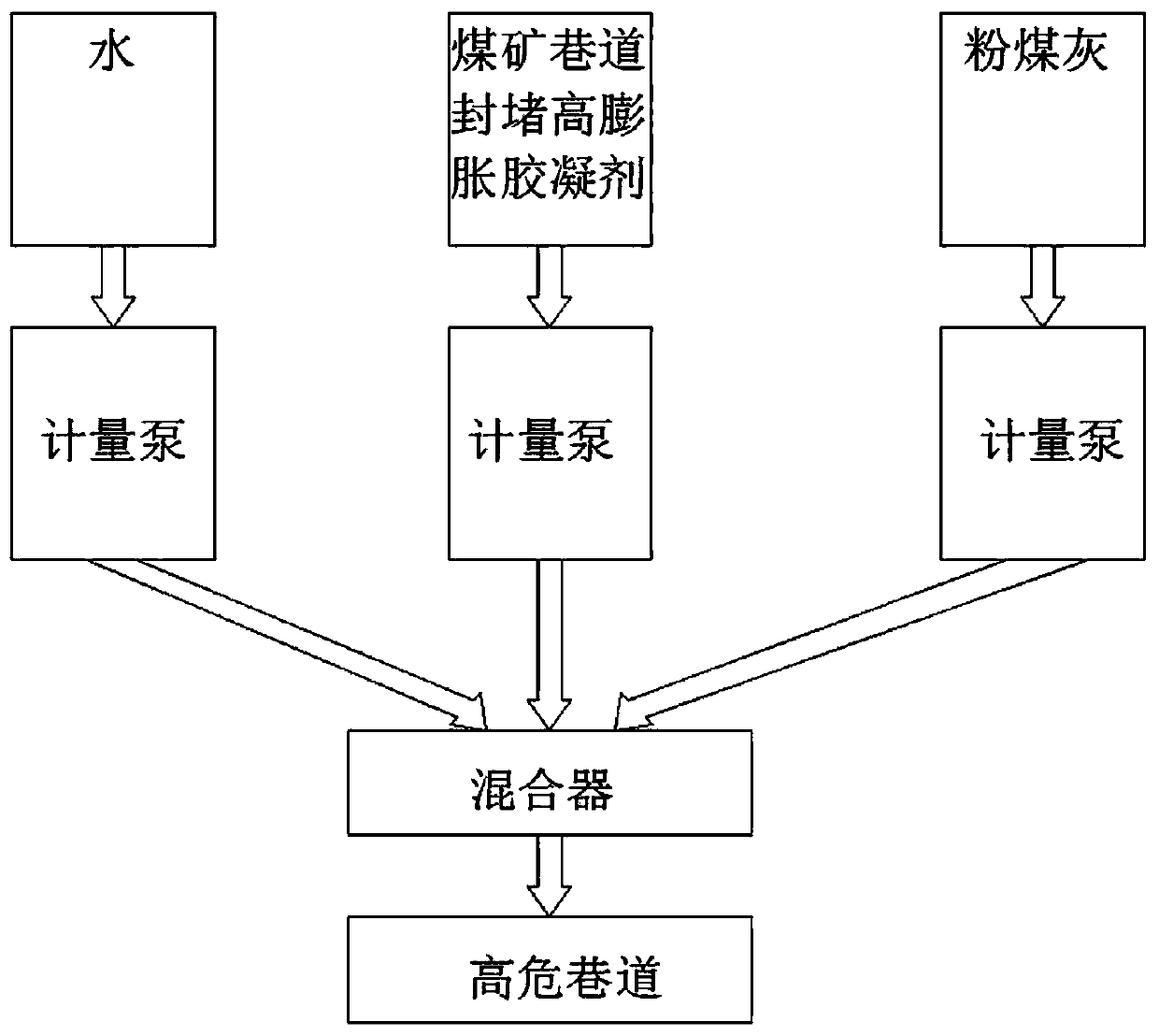

[0025] The coal mine roadway plugging high expansion gelling agent material of the embodiment of the present invention 1-3 is carried out performance measurement, and during construction, the weight ratio of coal mine roadway blocking high expansion gelling agent, fly ash and others is 1:4: 5. The results are described in the table below.

[0026] 7-day strength (MPa) 28 day strength (MPa) Example 1 2.1 3.5 Example 2 1.5 2.5 Example 3 1.1 2.1

[0027] It can be seen from the above table that the coal mine roadway sealing high expansion gelling agent of the present invention has good strength and meets the needs of construction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com