Syrup heating device

A technology of syrup and heating barrel, which is applied in the field of food processing, which can solve the problems of inconsistent sweetness and taste of puffed food, and great effort, and achieve the effect of preventing uneven syrup, replenishing water loss, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

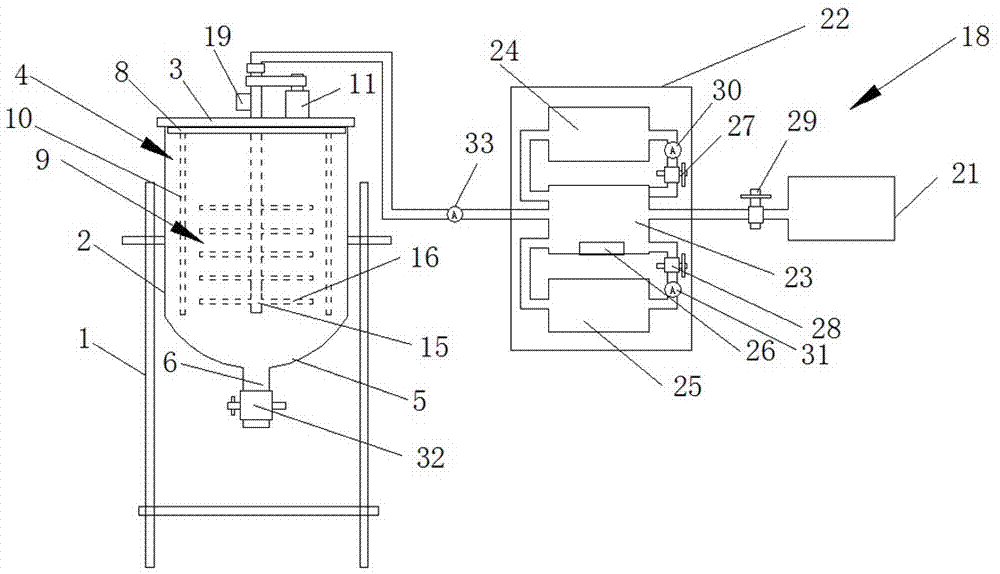

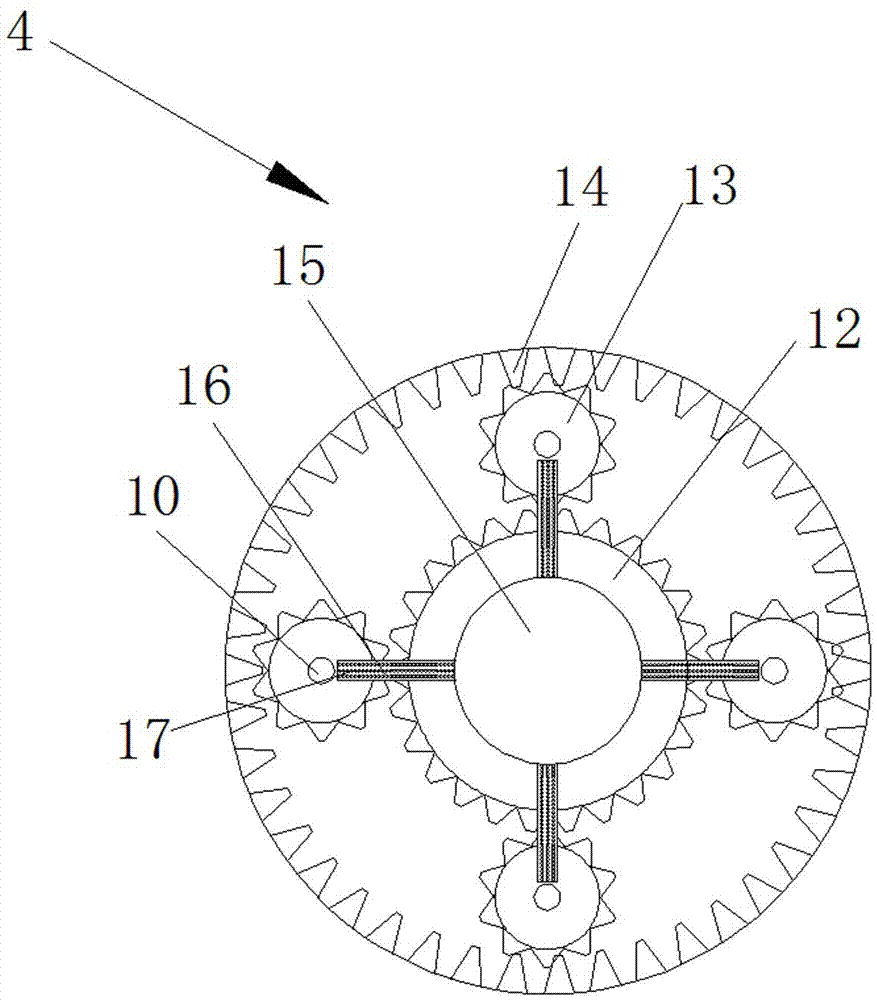

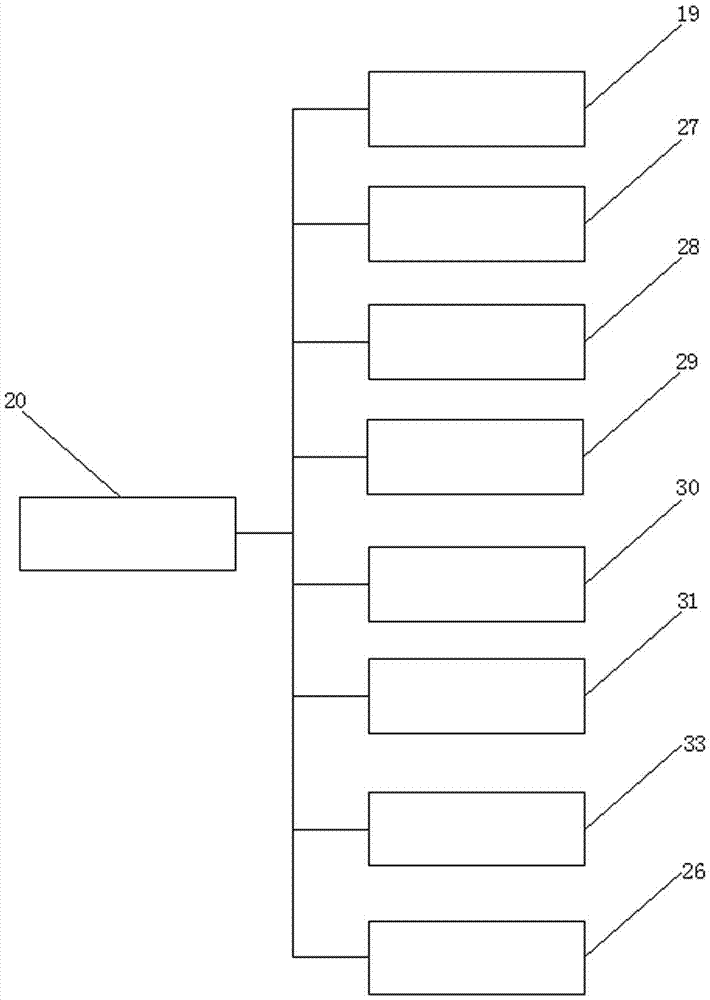

[0021] Such as figure 1 , figure 2 As shown, a syrup heating device includes a frame 1, a heating barrel 2, an upper cover 3 and a stirring mechanism 4; the heating barrel 2 is fixedly connected to the frame 1, and the bottom of the heating barrel 2 is a concave arc surface 5. A slurry outlet 6 is provided at the center of the concave arc surface 5; the upper cover 3 is detachably connected to the heating barrel 2, and the stirring mechanism 4 is arranged under the upper cover 3; the stirring mechanism 4 includes a planetary gear mechanism 8. Central stirring member 9, auxiliary stirring rod 10 and stirring motor 11; the stirring motor 11 is arranged on the upper end surface of the loam cake 3, and the central stirring member 9 includes a vertically arranged hollow central rod 15 and a vertically arranged Some hollow props 16 on the centra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com