Manufacturing method of bamboo chip for manufacturing the solubility pulp and thereof

A manufacturing method and soluble technology, applied in papermaking, textiles and papermaking, pulping of cellulose raw materials, etc., can solve the problems of alpha cellulose destruction, high transportation costs, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] [25] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. First of all, it should be noted that parts with the same or similar functions in the drawings use the same reference signs.

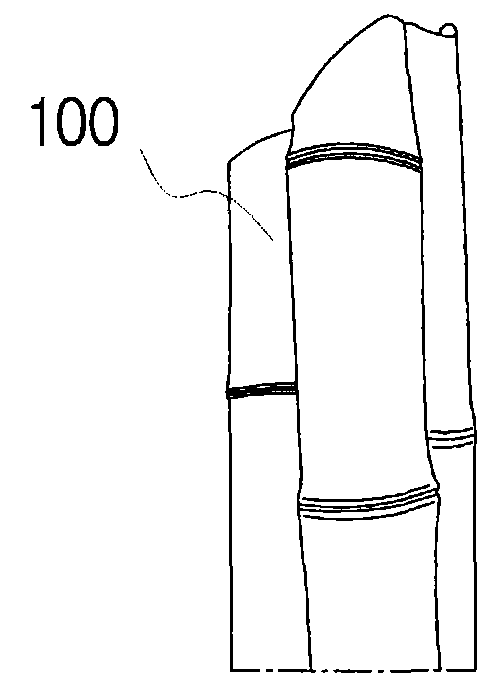

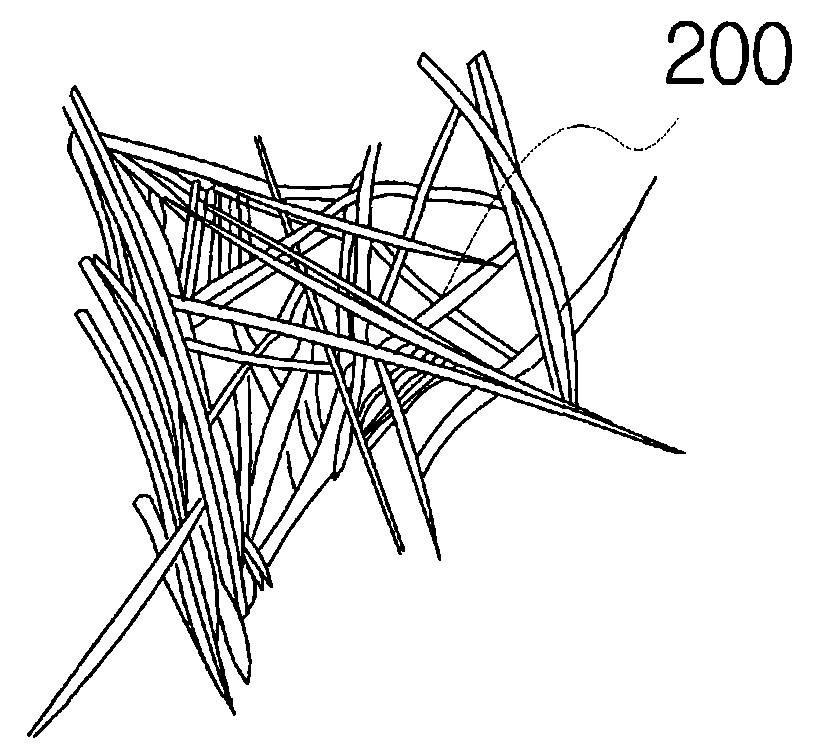

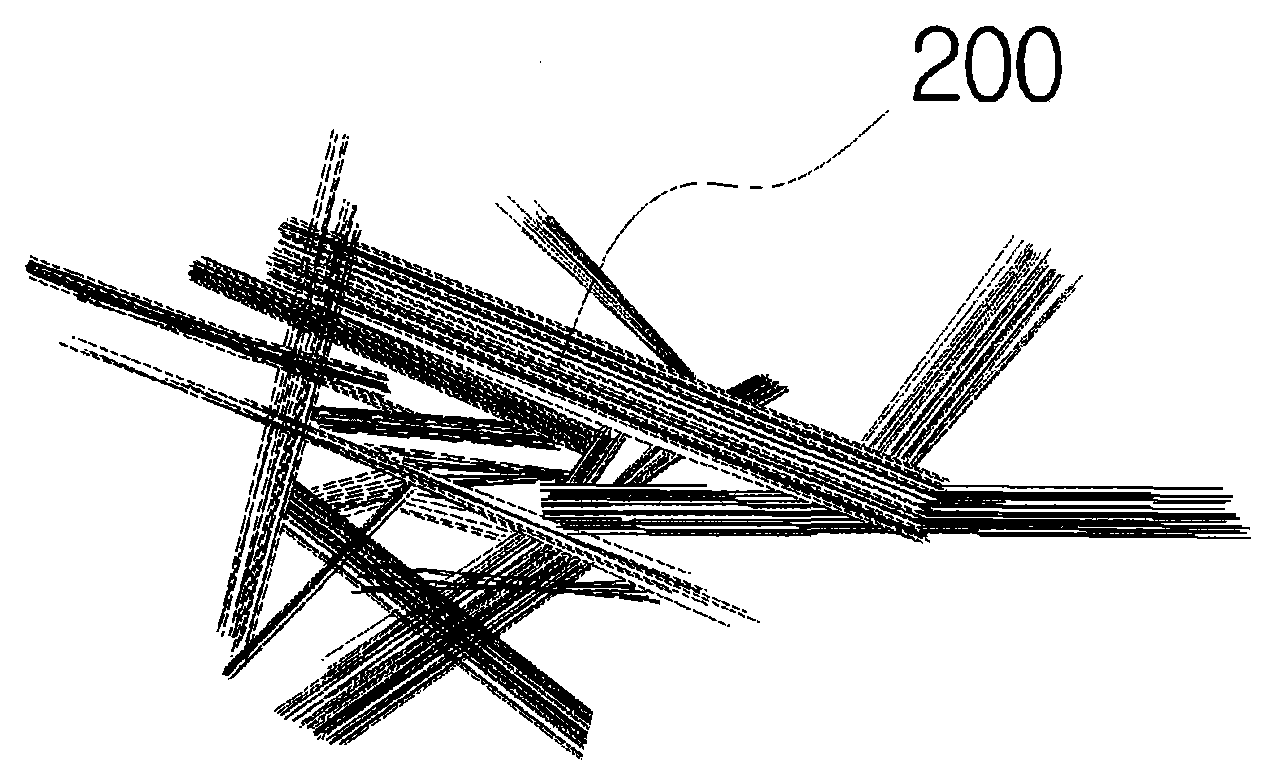

[0029] [26] figure 1 Bamboo 100 for use in the present invention is shown, figure 2 with image 3 A bamboo chip 200 made of bamboo 100 in an embodiment of the present invention is shown.

[0030] [27] The process of the present invention includes the steps of: harvesting bamboo in a mountainous area, removing bamboo branches and leaves from the bamboo, transporting the bamboo to a factory for making bamboo chips, removing the knots from the transported bamboo, and removing the knots from the bamboo. Bamboo is fed into the process of making bamboo chips.

[0031] [28] The process of making bamboo chips includes the steps of: transporting bamboo, cutting and rolling the delivered bamboo in the length direc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com