Metal-doped oxidative conductive carbon black cladded lithium manganese phosphate and preparation method thereof

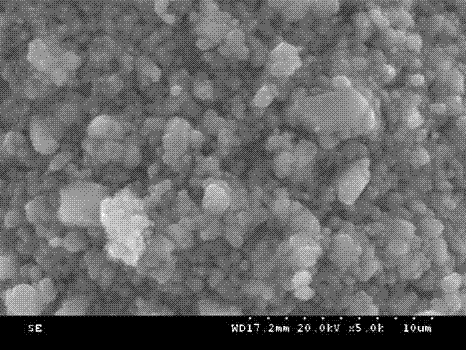

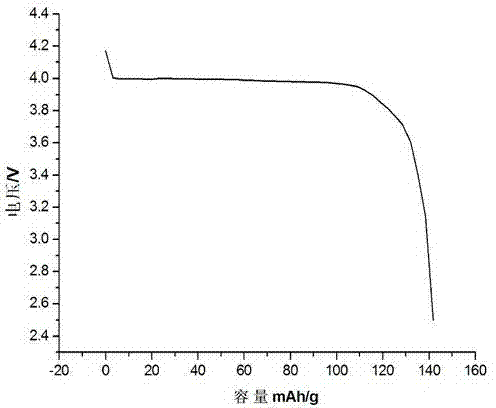

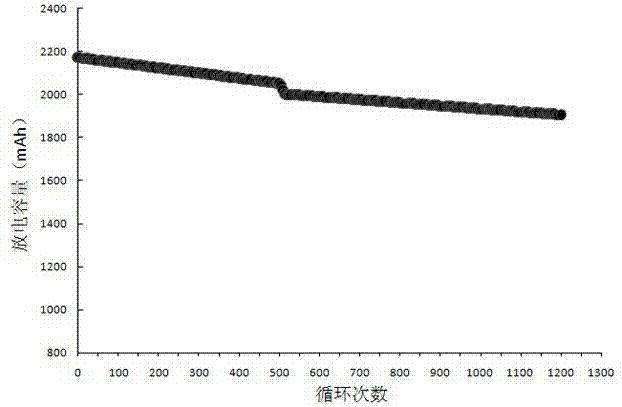

A technology of black-coating lithium manganese phosphate and oxidized conductive carbon black, which is applied in circuits, electrical components, battery electrodes, etc., can solve the problems of poor batch stability of lithium manganese phosphate, large amount of carbon source added, and low specific capacity, etc. problems, to achieve the effects of regular crystal lattice, good cycle performance and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Preparation of oxidized conductive carbon black

[0046] (1) Anneal the conductive carbon black at 270°C for 15h.

[0047] (2) Soak the conductive carbon black obtained in step (1) in a strong oxidizing agent, the strong oxidizing agent is 10mol / L nitric acid solution, the soaking temperature is 60°C, and the mass ratio of conductive carbon black to nitric acid solution is 1:40, After filtering, the filter residue is washed until the pH is neutral, and finally dried to obtain oxidized conductive carbon black.

[0048] (2) Preparation of metal-doped oxidized conductive carbon black coated lithium manganese phosphate

[0049] (a) Weigh the lithium source compound, manganese source compound, phosphorus source compound and metal dopant according to the ratio of lithium element: manganese element: phosphorus element: metal doping element molar ratio of 1:0.999:1:0.001, wherein The lithium source compound is lithium dihydrogen phosphate, the manganese source compound is...

Embodiment 2

[0065] (1) Preparation of oxidized conductive carbon black

[0066] (1) Anneal the conductive carbon black at 280°C for 13h.

[0067] (2) Add the conductive carbon black obtained in step (1) into a strong oxidizing agent for soaking. The strong oxidizing agent is a mixed solution composed of 10mol / L nitric acid solution and 10mol / L sulfuric acid solution in a mass ratio of 1:3, and the soaking temperature is 70°C , the mass ratio of conductive carbon black to the mixed solution is 1:30. After filtration, the filter residue is washed until the pH is neutral, and finally dried to obtain oxidized conductive carbon black.

[0068] (2) Preparation of metal-doped oxidized conductive carbon black coated lithium manganese phosphate

[0069] (a) Weigh the lithium source compound, manganese source compound, phosphorus source compound and metal dopant according to the ratio of lithium element: manganese element: phosphorus element: metal doping element molar ratio of 1:0.9:1:0.1, wherei...

Embodiment 3

[0074] (1) Preparation of oxidized conductive carbon black

[0075] (1) Anneal the conductive carbon black at 290°C for 12h.

[0076] (2) Add the conductive carbon black obtained in step (1) to soak in a strong oxidant, the strong oxidant is ammonium persulfate solution with a mass concentration of 20g / L, the soaking temperature is 25°C, the mass ratio of conductive carbon black to the mixed solution The ratio is 1:50. After filtration, the filter residue is washed until the pH is neutral, and finally dried to obtain oxidized conductive carbon black.

[0077] (2) Preparation of metal-doped oxidized conductive carbon black coated lithium manganese phosphate

[0078] (a) Weigh lithium source compound, manganese source compound, phosphorus source compound and metal dopant according to the ratio of lithium element: manganese element: phosphorus element: metal doping element molar ratio of 1:0.95:1:0.05, wherein The lithium source compound is formed by mixing lithium dihydrogen p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com