Water-conservancy-project high-water-head tunnel spillway bottom plate concrete crack defect inhibitor and preparation method thereof

A technology of high water head and flood discharge tunnel, applied in the field of admixtures for suppressing cracks and concrete crack defect inhibitors, to achieve the effect of reducing cracks and penetrating cracks, uniform concrete structure, and reducing surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

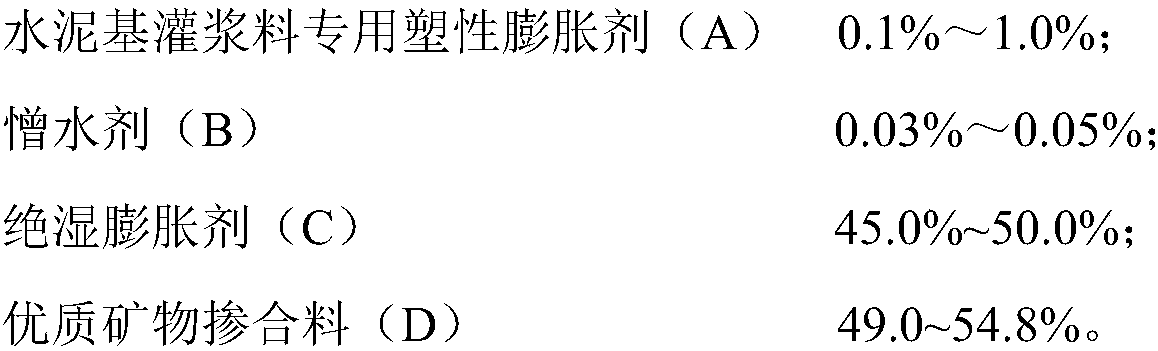

Embodiment 1

[0024] The concrete crack defect inhibitor for the floor of the hydraulic high-head flood discharge tunnel in this embodiment has the following weight components: special plastic expansion agent for cement-based grouting material: 0.3%; polysiloxane powder: 0.03%; calcium oxide clinker and gypsum composite Expansion agent: 45.0%; pozzolan ultrafine aluminosilicate mineral powder: 54.67%, the above components are accurately weighed by weight percentage, and the present invention is prepared according to the process described in Example 7.

Embodiment 2

[0026] The concrete crack defect inhibitor for the floor of the hydraulic high-head flood discharge tunnel in this embodiment has the following weight components: special plastic expansion agent for cement-based grouting material: 0.5%; polysiloxane powder: 0.05%; calcium sulfoaluminate-calcium oxide Clinker and gypsum composite expansion agent: 45.0%; pozzolan ultrafine aluminosilicate mineral powder: 49.45%, the above components are accurately weighed by weight percentage, and the present invention is prepared according to the process described in Example 7.

Embodiment 3

[0028] The concrete crack defect inhibitor for the floor of the hydraulic high-head flood discharge tunnel in this embodiment has the following weight components: plastic expansion agent for cement-based grouting material: 0.3%; polysiloxane powder: 0.05%; R-type magnesium oxide-calcium oxide Clinker and gypsum composite expansion agent: 50.0%; pozzolan ultrafine aluminosilicate mineral powder: 49.47%, the above components are accurately weighed by weight percentage, and the present invention is prepared according to the process described in Example 7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com