Method and equipment for producing paper pulp by gases mixed explosion

A technology of blasting and pulping, which is applied to pulping, papermaking, textiles and papermaking of cellulose raw materials, etc., can solve the problems of inability to recycle, difficult to treat pollutants, and high treatment costs, so as to reduce the pollution load and the difficulty of water treatment. The effect of improving the comprehensive utilization rate and reducing the cost of water treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

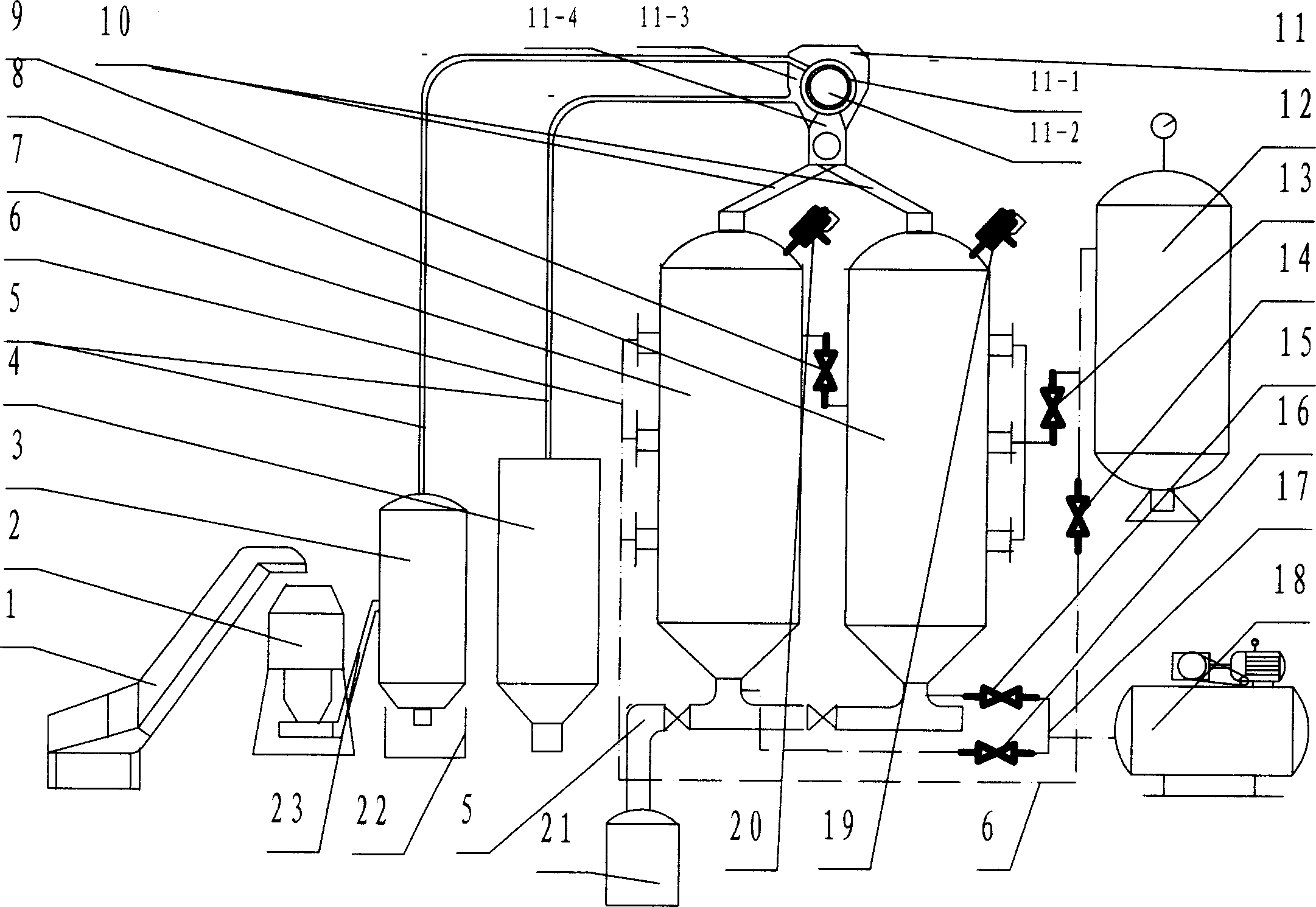

[0019] As shown in the accompanying drawings, the gas mixed explosion pulping equipment of the present invention consists of a feeder 1, a mower 2, a sorter 3, a dust collector 4, a digester 7,8, a feeder 11, an air pump 18, and The feeder 21 is formed. After the wheat straw is loaded into the feeder 1, the feeder 1 automatically feeds the wheat straw into the trimmer 2, and the wheat straw crushed by the trimmer enters the winnowing machine 3 through the feeding pipe 23 under the gravity of the wind , adjust the size of the damper of the winnowing machine, and change the wind speed, so that the soil and rocks in the wheat straw fall into the waste bin from the bottom of the winnowing machine, and the wheat straw, wheat leaves, wheat library, wheat awns, and dust enter through the feeding pipe 5 under the gravity of the wind In the feeding chamber 11-2 of the feeder 11, wheat leaves, barley, awns, dust and other smaller and lighter substances that cannot be used as papermaking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com