Grain sunning field

A grain and barn technology, applied in the field of grain drying field, can solve the problems of time cost, high labor cost, loss of market competitiveness of rice, etc., and achieve the effect of ensuring sufficiency and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

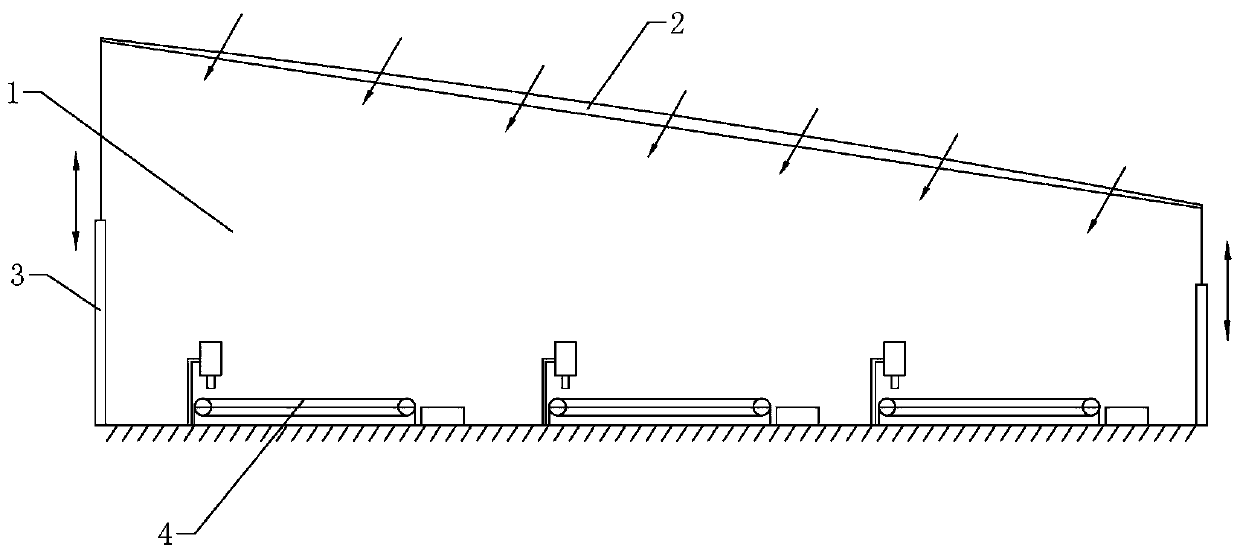

[0031] according to Figure 1 to Figure 6 As shown, a grain drying field includes: a drying square (1), a light-transmitting ceiling (2), an electric lifting pole (3) and several drying devices (4), and the light-transmitting ceiling (2) passes through the electric The lifting rod (3) is fixed above the drying square (1), the drying device (4) is set at the bottom of the light-transmitting ceiling (2), the light-transmitting ceiling (2) is a convex lens, and the light-transmitting The light ceiling (2) changes the light transmission angle through the electric lifting rod (3).

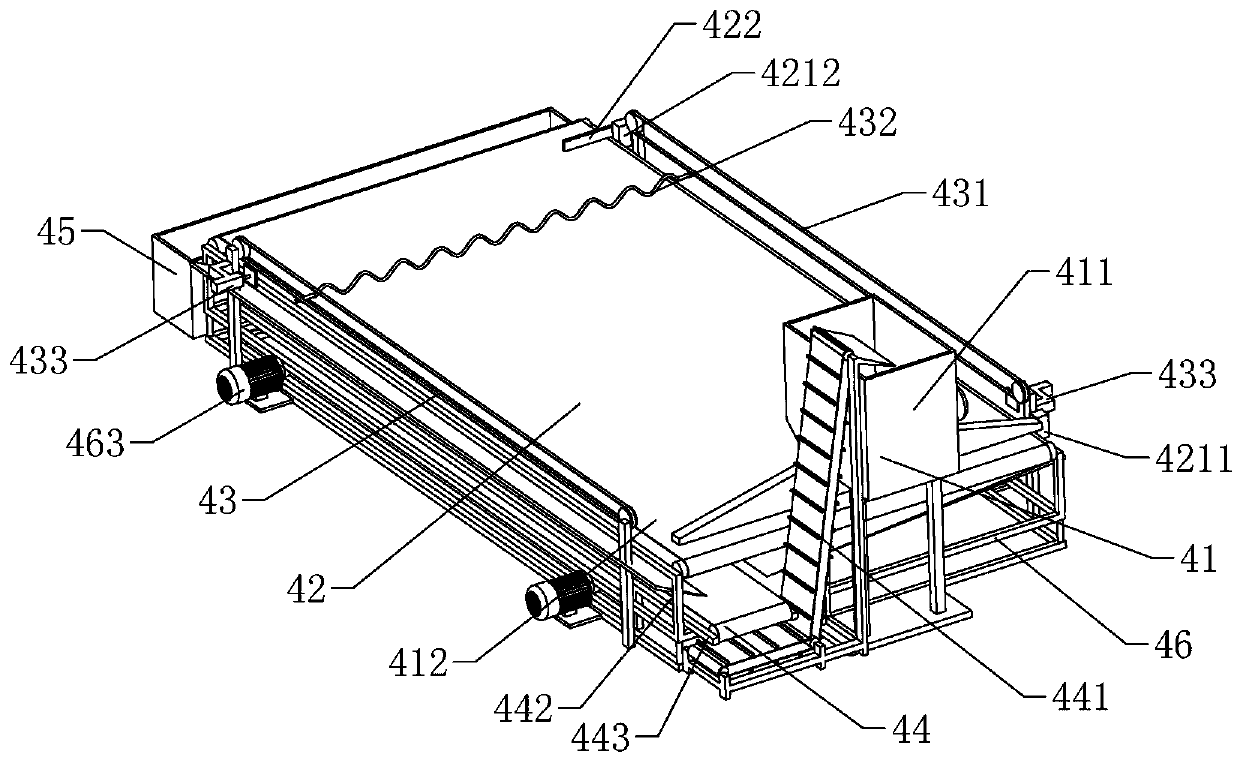

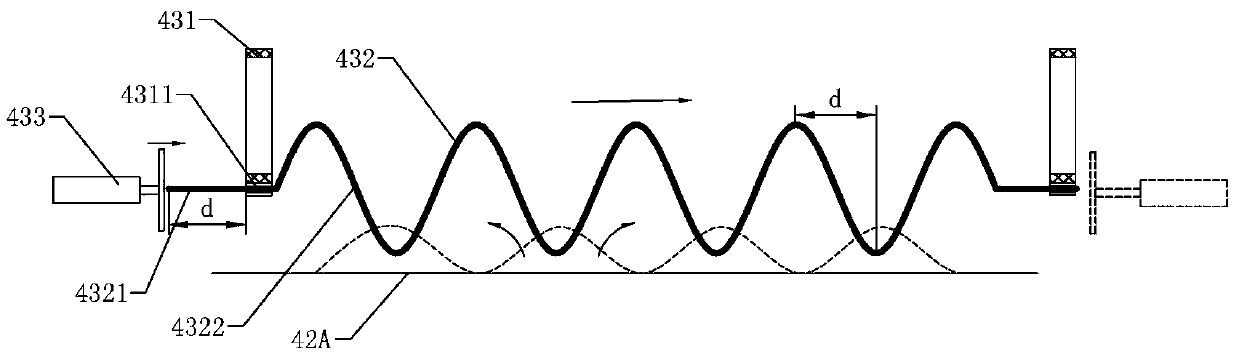

[0032] Grain drying device 4 comprises, lower barn 41, grain drying belt 42 and valley turning mechanism 43, falling grain recovery mechanism 44 and receiving barn 45, and lower barn 41 is used to scatter grain on the grain drying belt 42, and valley turning mechanism 43 is used for The grain on the grain drying belt 42 is automatically turned over; the lower barn 41 is arranged at one end of the grain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com