Vacuum sealed electrical wire outlet structure

A vacuum sealing and electrical technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of medium leakage or external medium infiltration, long processing cycle, high cost, etc., achieve simple structure, low cost, and prevent internal and external leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

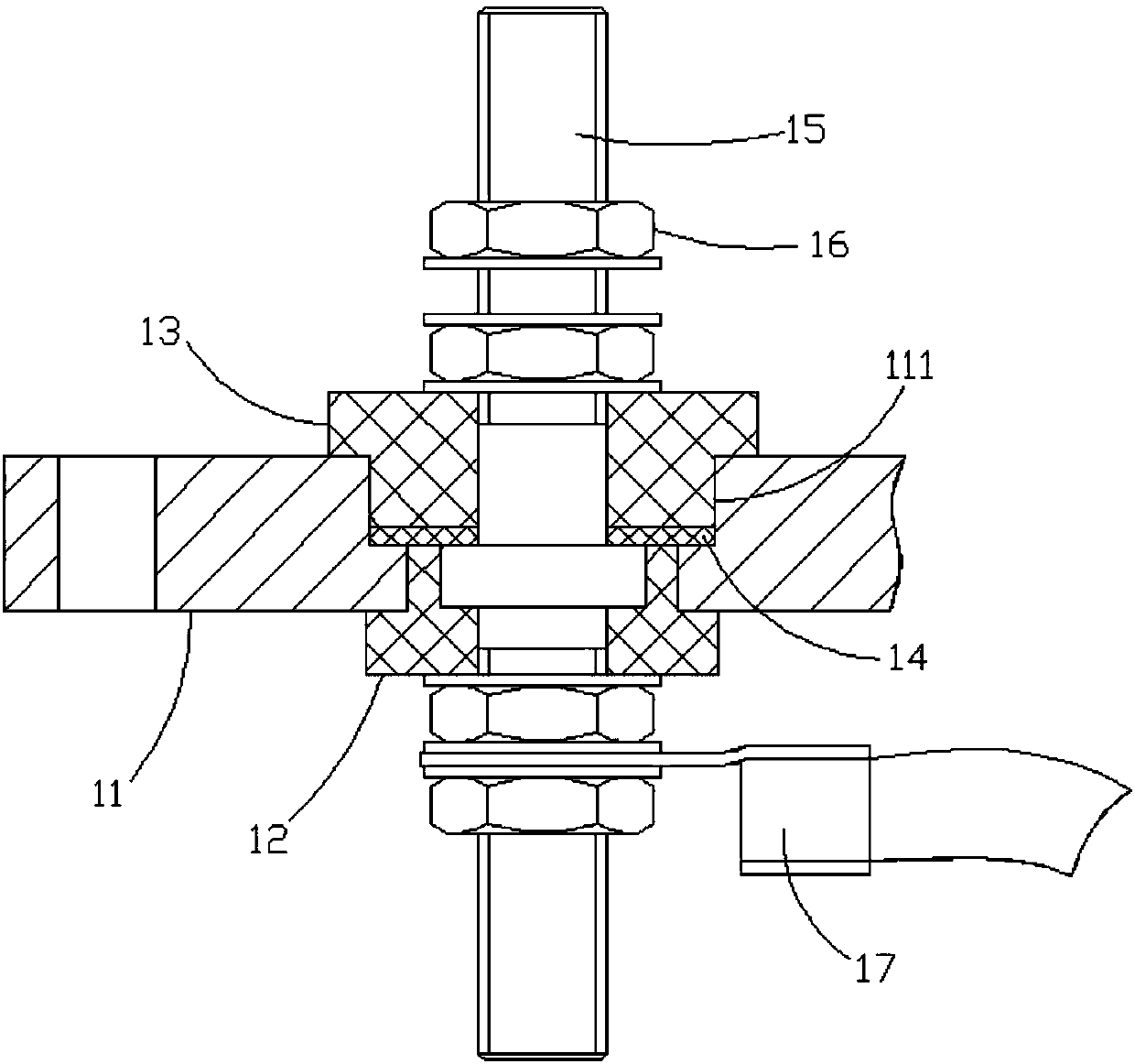

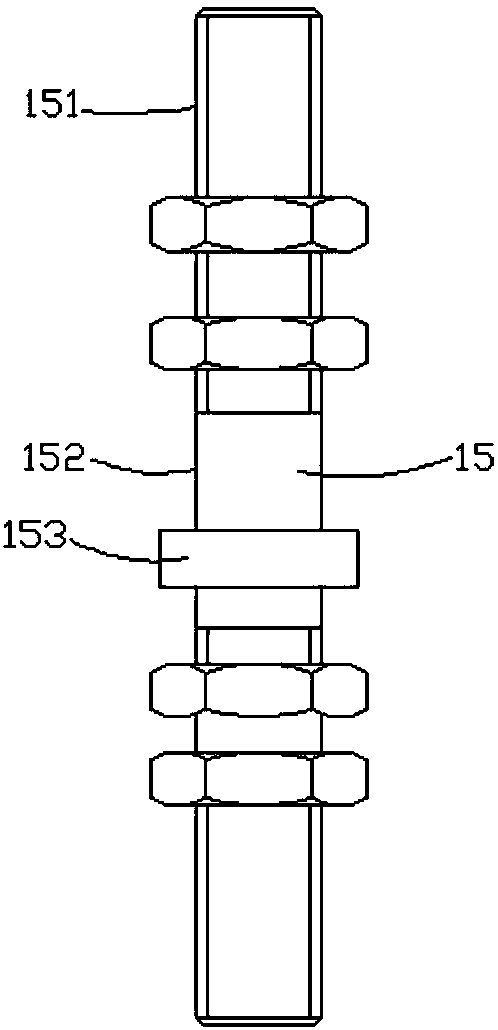

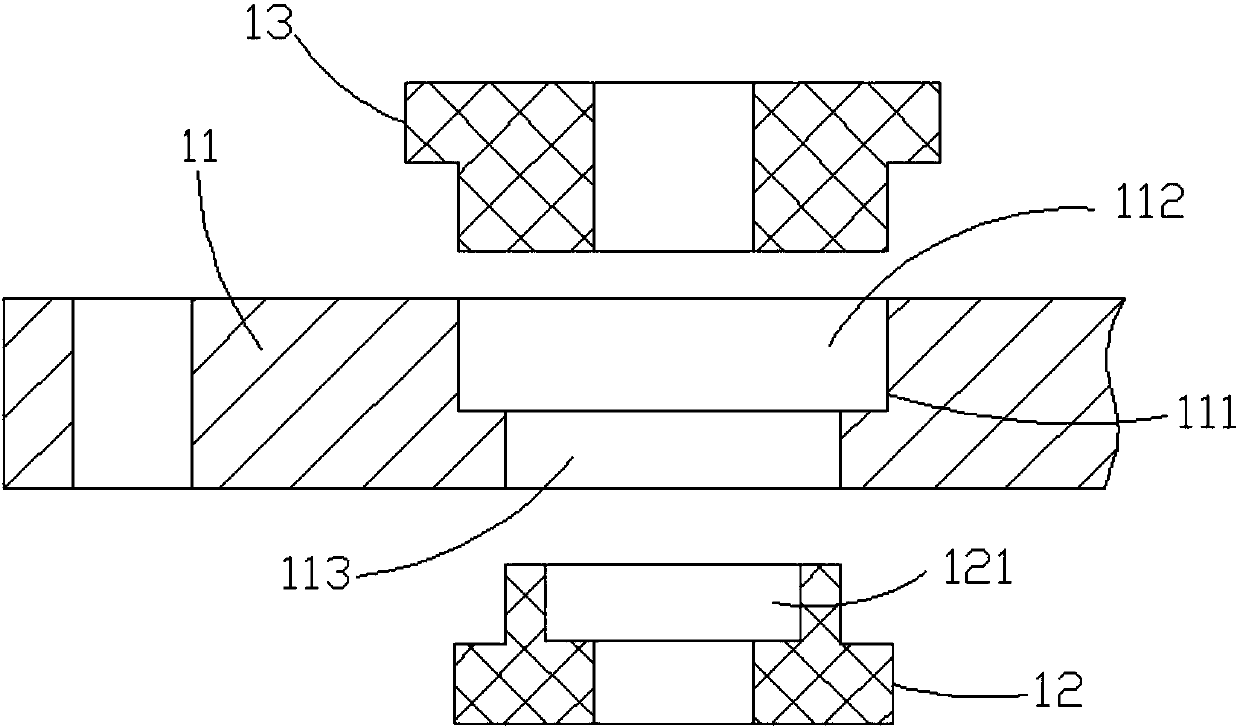

[0016] Such as Figure 1 to Figure 4 As shown, the present invention discloses a vacuum-sealed electrical outlet structure, comprising a wiring cover 11, an inner insulating sleeve 12, an outer insulating sleeve 13, a sealing ring 14, a terminal post 15, a hex nut 16 and a wire lug 17, and the wiring cover 11 is provided with There is a connection hole 111, and the terminal post 15 is connected in the connection hole 111. The inner insulating cover 12, the outer insulating cover 13 and the sealing ring 14 are all sleeved on the terminal post 15, and the inner insulating cover 12 and the outer insulating cover 13 are respectively placed On the inner and outer sides of the wiring cover 11, the sealing ring 14 is placed between the inner insulating sleeve 12 and the outer insulating sleeve 13, a number of hex nuts 16 are threaded on the upper and lower sides of the termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com