Throttle valve

A throttle valve and valve seat technology, which is applied to fluid pressure actuating devices, servo motor components, mechanical equipment, etc. Possibilities, increased work stability, reduced machining and assembly accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

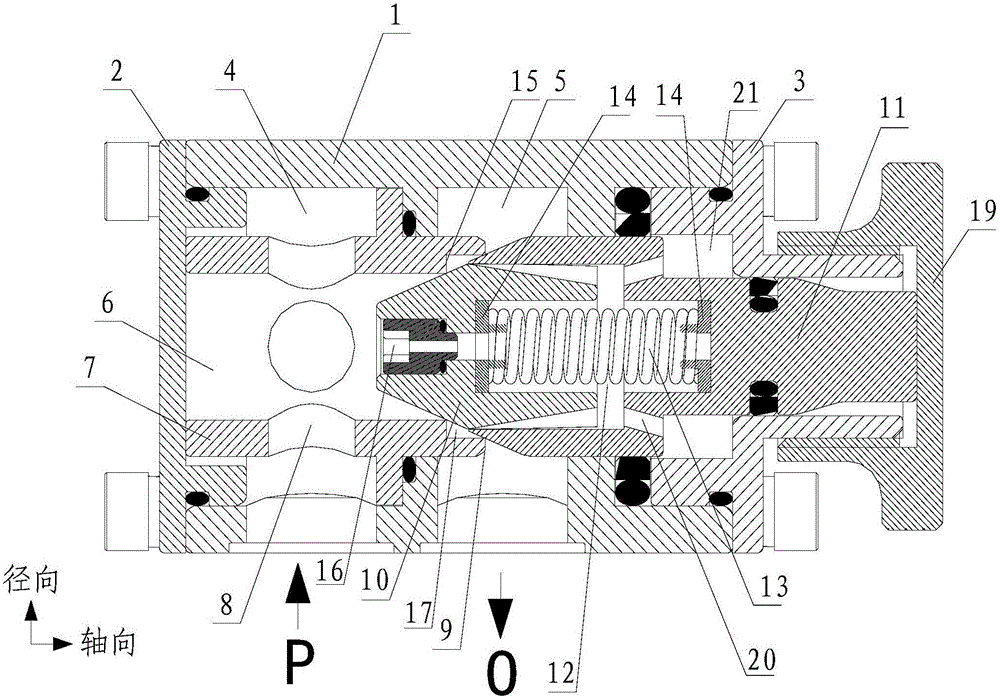

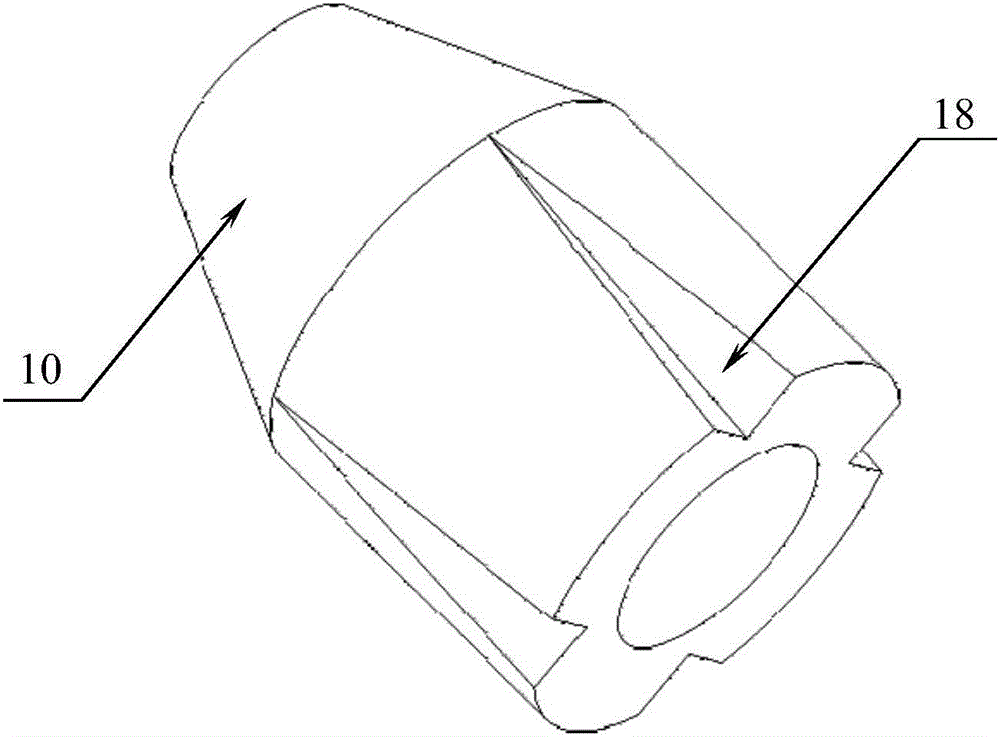

[0025] Example 1, such as figure 1 As shown, this embodiment discloses a throttle valve, including a valve body 1 with a liquid inlet P and a liquid outlet O, and the two ends of the valve body 1 are respectively provided with a left end cover 2 and a right end cover 3, as a As an alternative, in this embodiment, the left end cover 2 and the right end cover 3 are connected to the valve body 1 by bolts. The valve body 1 is also provided with a liquid inlet chamber 4 communicating with the liquid inlet P and a liquid outlet chamber 5 communicating with the liquid outlet O. A valve seat 7 with a cavity 6 is installed in the liquid inlet chamber 4, and the valve The hole 8 on the seat 7 makes the valve seat cavity 6 communicate with the liquid inlet chamber 4. As an alternative, there are four holes 8 on the valve seat 7 in this embodiment, and each hole 8 is along the valve seat. The radial directions of 7 are distributed in a cross. The valve port of the valve seat 7 is a two-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com