A kind of superfine natural pearl powder screening device

A screening device and pearl powder technology are applied in the field of ultra-fine natural pearl powder screening devices, which can solve the problems such as blocking holes of the screen, difficulty in discharging materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

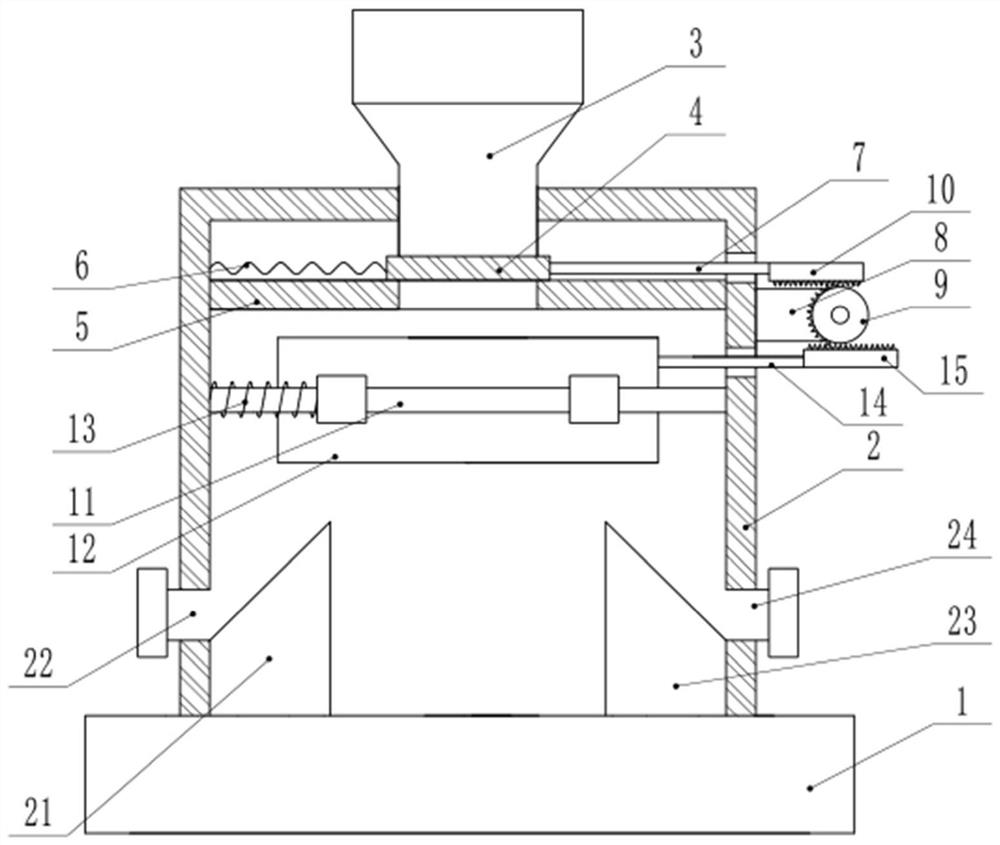

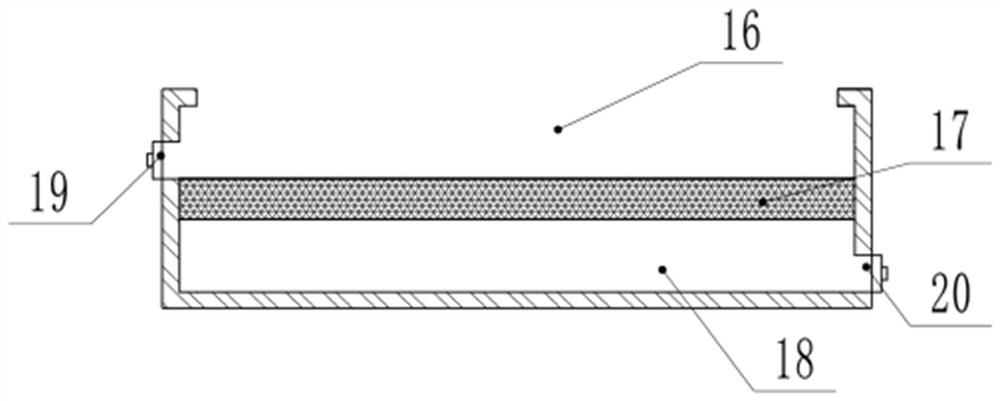

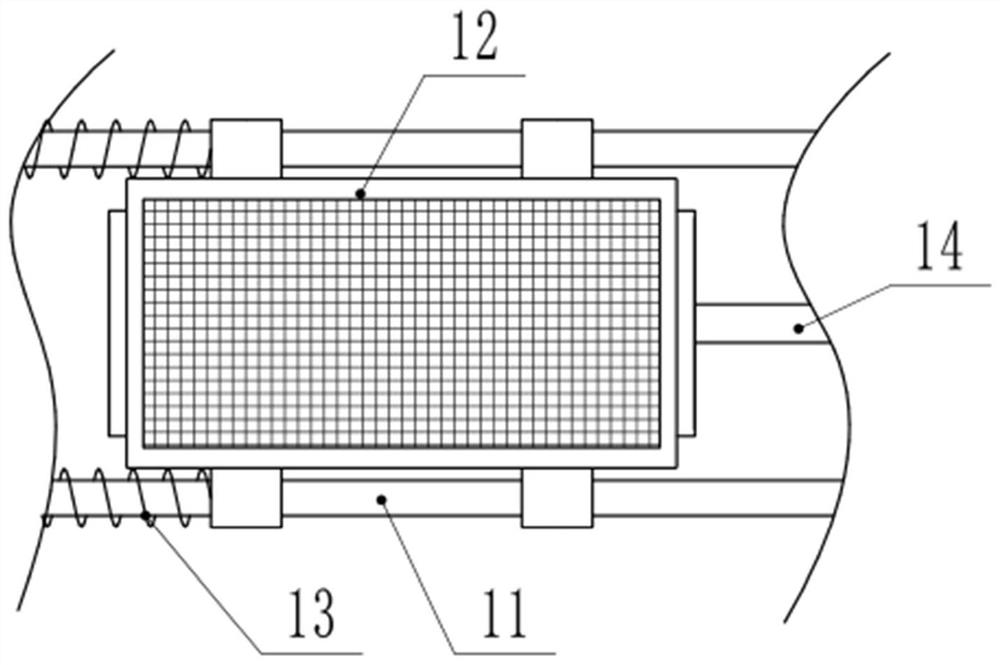

[0024] see Figure 1-3 , a superfine natural pearl powder screening device, comprising a base 1 and a screening box 2, the base 1 is provided with a screening box 2, the screening box 2 and the base 1 are fixedly connected by bolts, the screening box The sub-box 2 is provided with a feed funnel 3 for storage of the ground pearl powder. The inside of the screening box 2 is fixed with a leaking plate 5 by screws. The center of the leaking plate 5 has a circular drain. The material hole and the material leakage hole are located directly below the feeding funnel 3, and the lower side of the feeding funnel 3 is also provided with a material blocking plate 4, and a first spring is connected between the left side of the material blocking plate 4 and the inner wall on the left side of the screening box 2 6. The right side of the blocking plate 6 is thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com