Stone cutting cooling water treatment device

A technology for cooling water treatment and stone cutting, applied in the direction of separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of inconvenient use, slow sedimentation time, prolonging the time of cooling water treatment, etc., to prevent clogging of the screen , the effect of continuous and rapid filtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

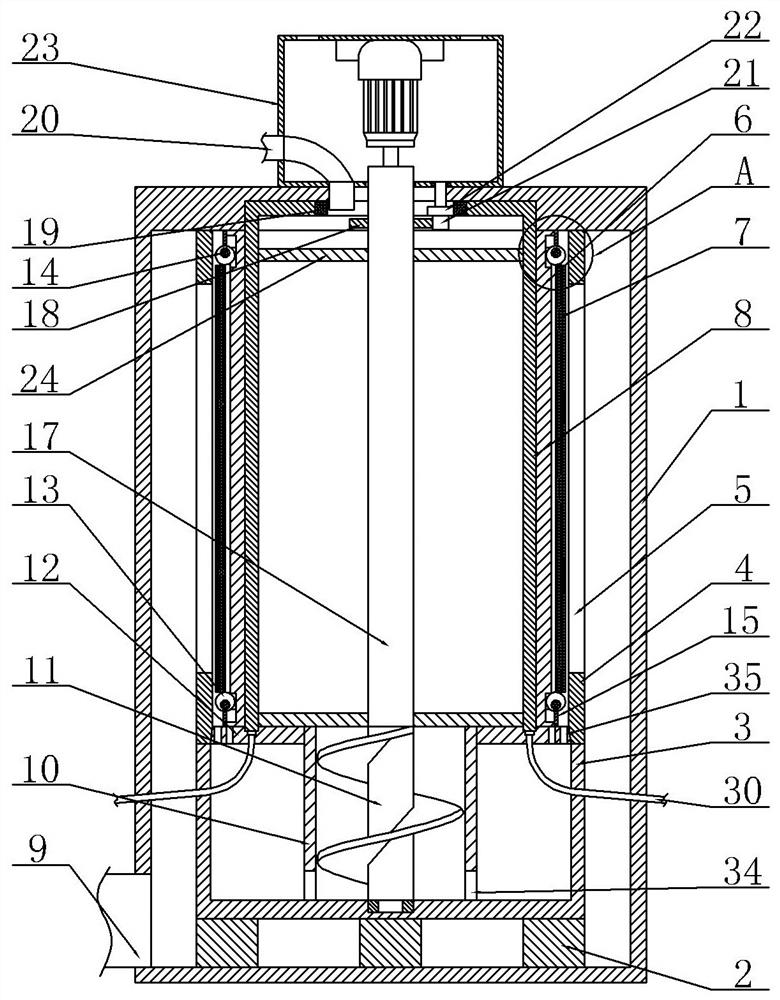

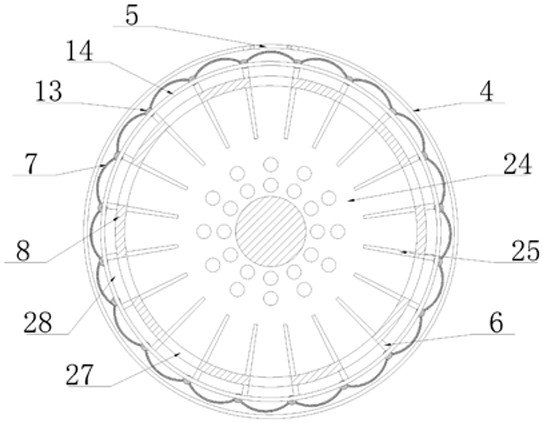

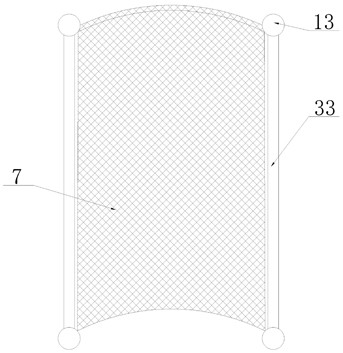

[0031] see Figure 1 to Figure 10, the present invention provides a technical solution: a stone cutting cooling water treatment device, comprising a filter barrel 1, a motor fixing box 23 arranged in the center of the upper surface of the filter barrel 1, and a drive fixedly installed on the inner top surface of the motor fixing box 23 The motor, wherein the device is only the first step of processing the cooling water, and the rest still have processes such as flocculation, but they are all in the prior art, so they will not be described in detail. , the upper surface of the backflow collection barrel 3 is fixedly connected with a screen b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com