Test tube cleaning equipment

A technology for cleaning equipment and test tubes, which is applied in the field of laboratory equipment, can solve problems such as time-consuming, heavy workload, and contamination, and achieve good cleaning effects and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

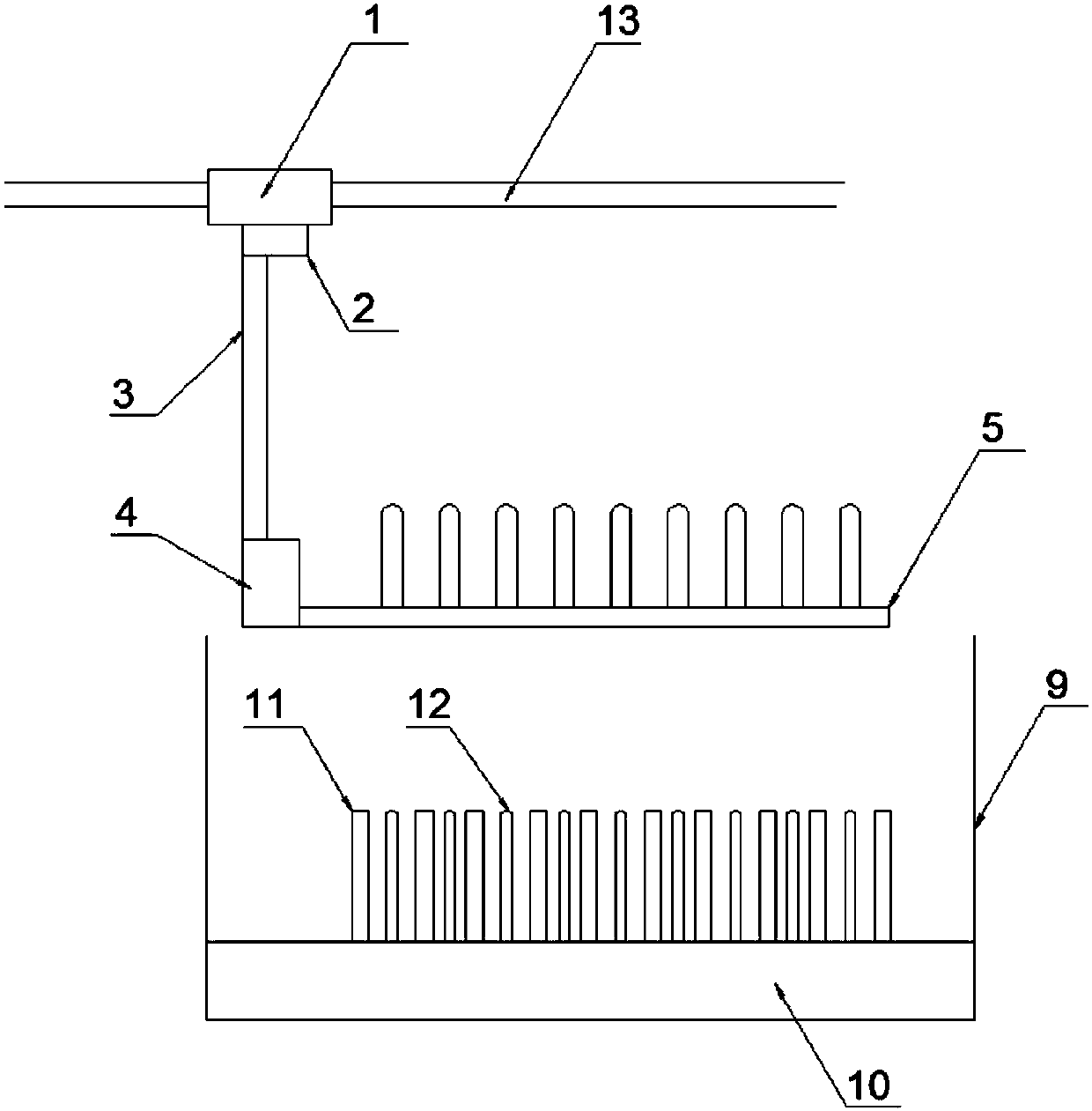

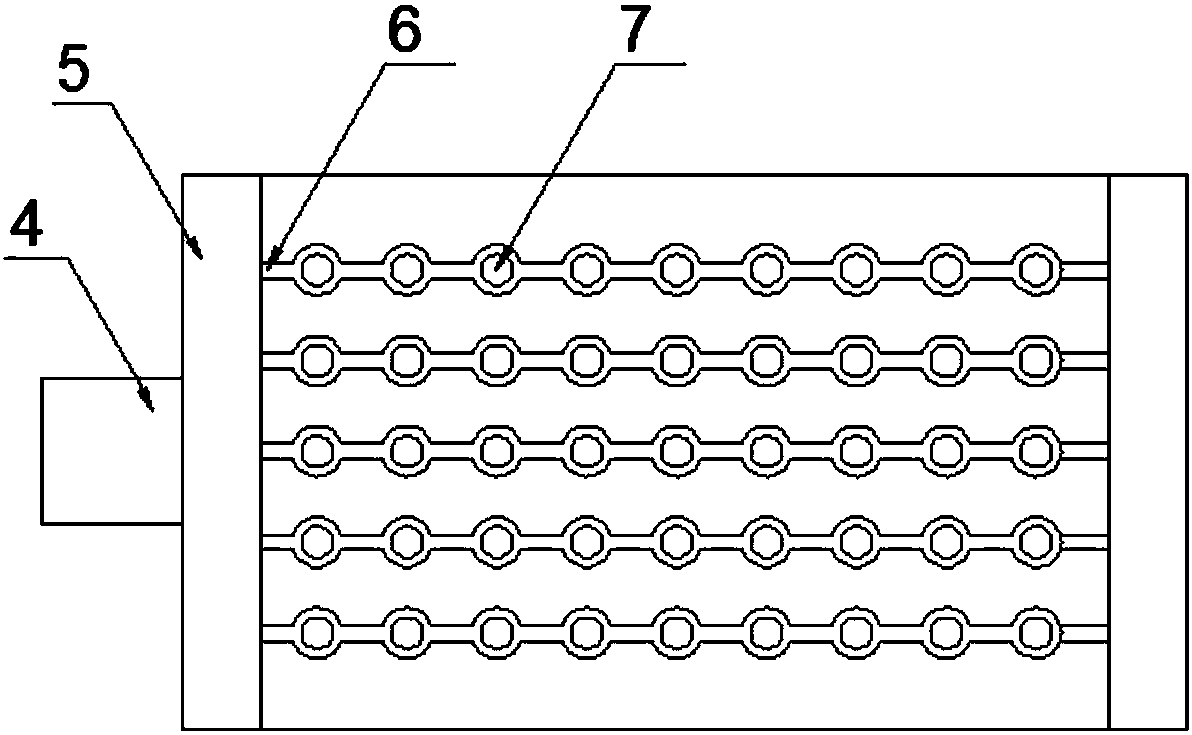

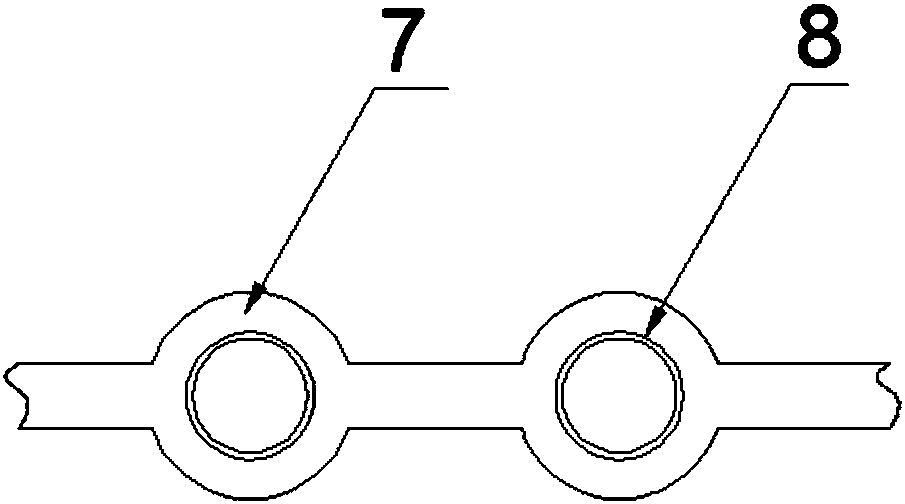

[0020] like Figure 1-5 as shown, figure 1 It is a structural schematic diagram of a test tube cleaning device proposed by the present invention, figure 2 It is a schematic diagram of the connection of the bracket and the test tube rack in the test tube cleaning equipment proposed by the present invention, image 3 It is the structural representation of the test tube rack in the test tube cleaning equipment proposed by the present invention, Figure 4 It is a partial structural schematic diagram of the test tube cleaning equipment proposed by the present invention, Figure 5 It is a structural schematic diagram of the outer rolling brush and the inner rolling brush in the test tube cleaning equipment proposed by the present invention.

[0021] refer to Figure 1-5 , a kind of test tube cleaning equipment that the present invention proposes, comprises walking device 1, driving mechanism 2, elevating rod 3, fixed block 4, support 5, test tube holder 6, cleaning pool 9, oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com