Bidirectional drive device

A two-way drive and drive technology, applied in hoisting devices, clockwork mechanisms, etc., can solve the problems of being unable to time-share and independently drive the movement of two components, so as to achieve high-efficiency utilization, good force transmission paths, and reduced quantities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

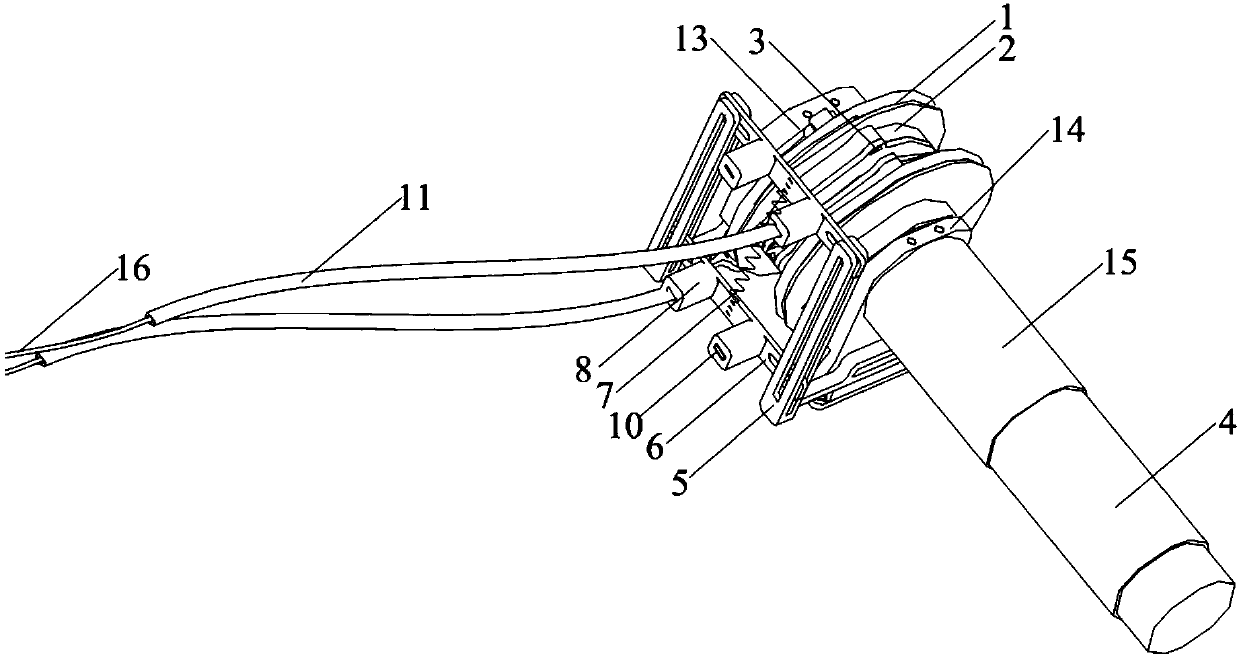

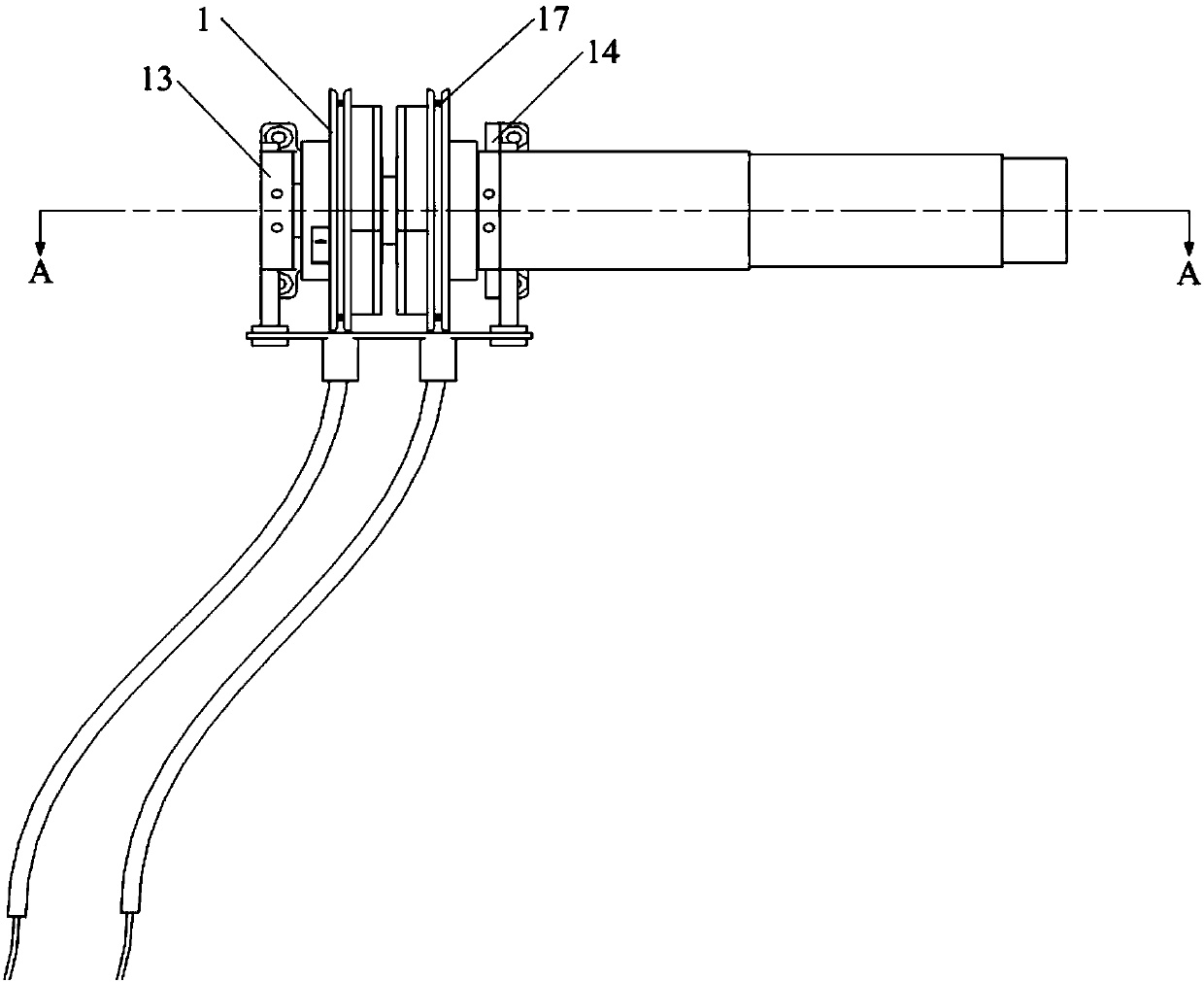

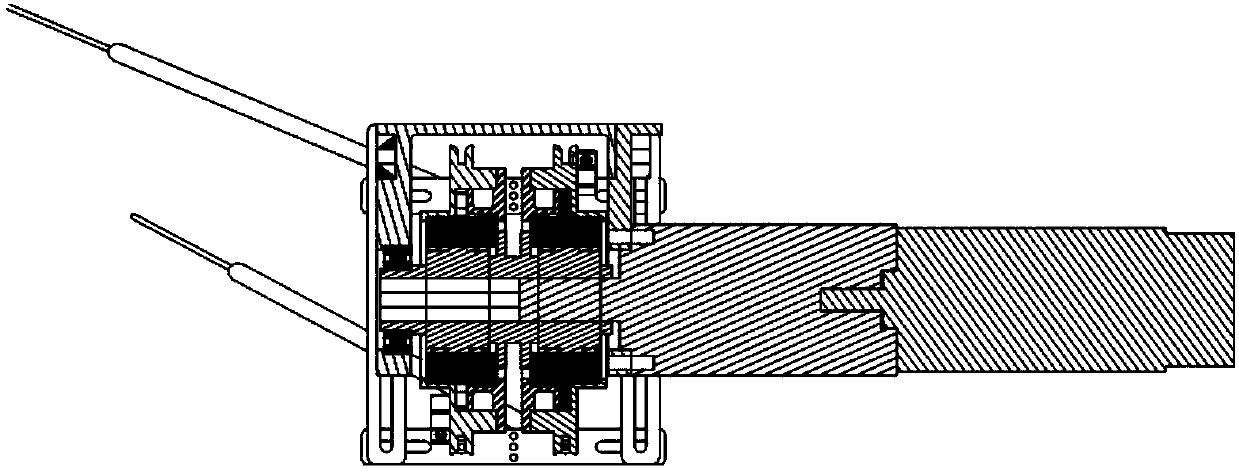

[0036] The bidirectional driving device provided by this embodiment, such as Figure 1 to Figure 8 As shown, it includes a bidirectional driver 4, a wire slot 1 (single-layer wire slot or multi-layer wire slot is acceptable) and a ratchet assembly. The ratchet assembly is divided into a positive ratchet assembly and a reverse ratchet assembly with opposite stop directions; The components are respectively socketed and fixed with the output shafts of the two-way drive 4; there are two wire slots 1, which are respectively connected to the positive ratchet assembly and the reverse ratchet assembly; the two-way drive 4 rotates forward, and the corresponding wire slot 1 is driven to rotate through the positive ratchet assembly. The slot 1 corresponding to the anti-ratchet assembly does not rotate; the two-way driver 4 rotates in reverse, and the corresponding slot 1 is driven to rotate by the anti-ratchet assembly, and the slot 1 corresponding to the positive ratchet assembly does no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com