High-precision vacuum gauge tube

A vacuum gauge and high-precision technology, applied in the direction of particle separation tube, ion diffusion discharge tube, etc., can solve the problems of measurement error and achieve the effect of accurate measurement and small thermal drift coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

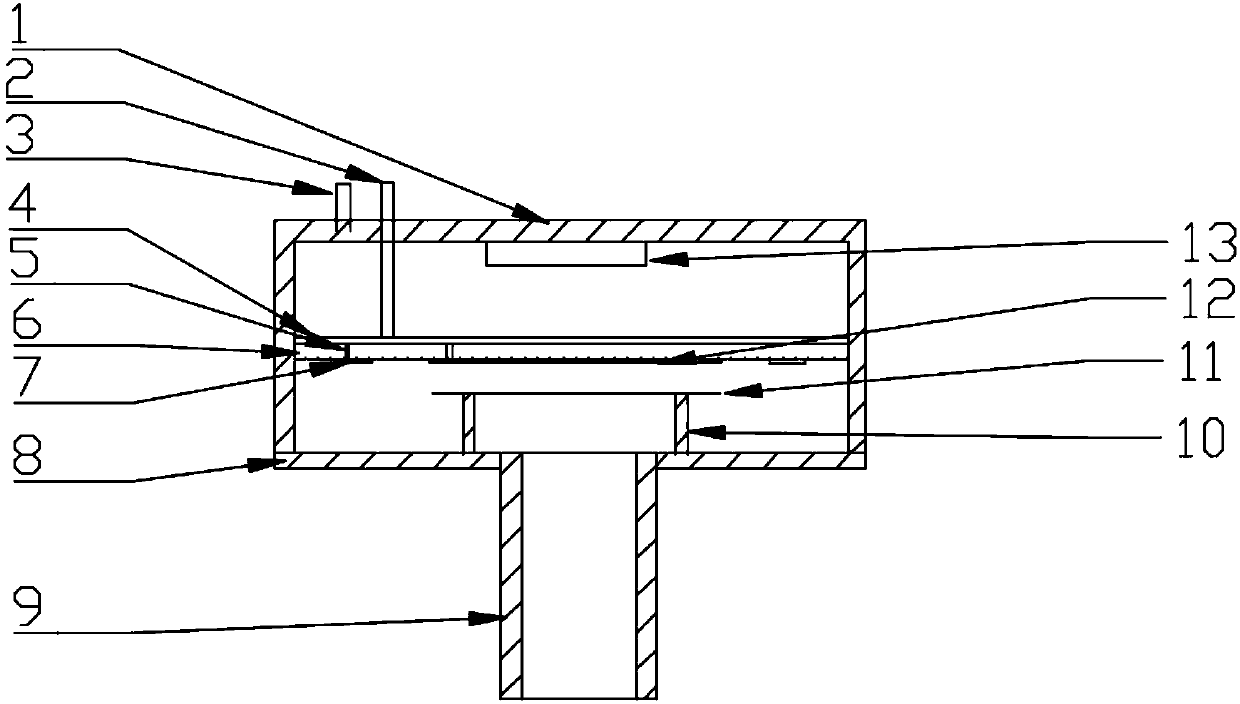

[0025] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0026] Such as figure 1 As shown, the embodiment of the present invention provides a high-precision vacuum gauge, including: a housing, a diaphragm 11, a fixed electrode 6, a first electrode post 3, a second electrode post 2, and an air inlet 9, wherein the diaphragm 11 and The fixed electrode 6 forms a variable capacitor. The shell includes an upper cover shell 1 and a lower cover shell 8, the upper cover shell 1 and the lower cover shell 8 are welded together, and the material of the shell is Hastelloy. The film sheet 11 is fixedly arranged inside the housing, and the internal space of the housing is divided into a vacuum space and a measured space; the material of the film sheet 11 is Hastelloy, and the thickness of the film sheet 11 is 30 M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com