Mouse cage type steel rebar prestress straightening machine

A technology for prestressing and straightening machines, used in metal processing, metal processing equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

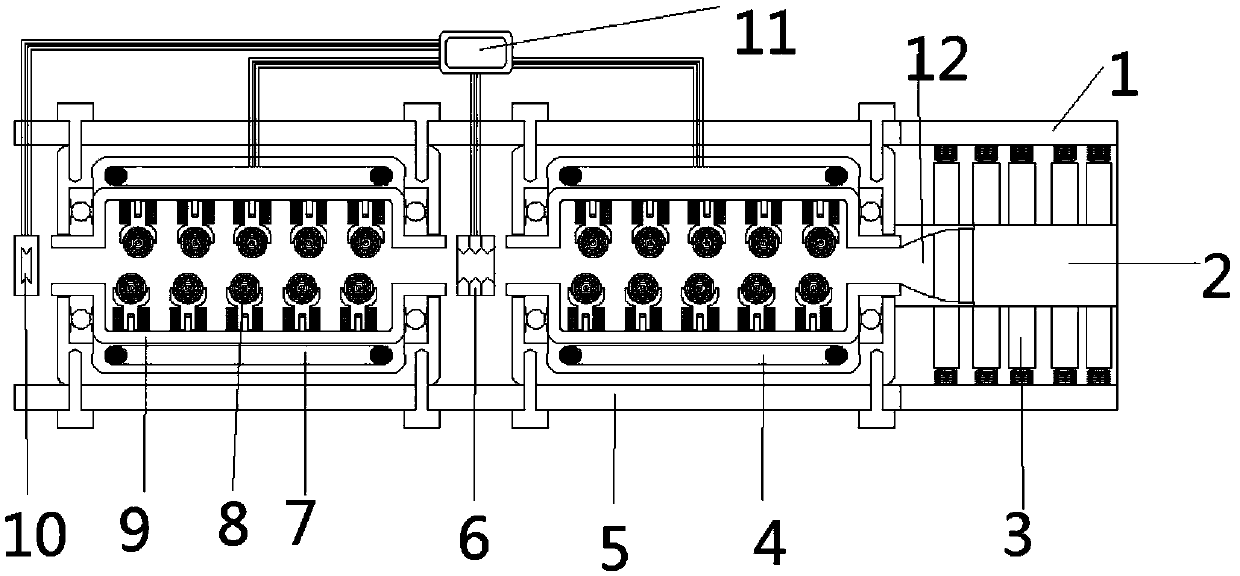

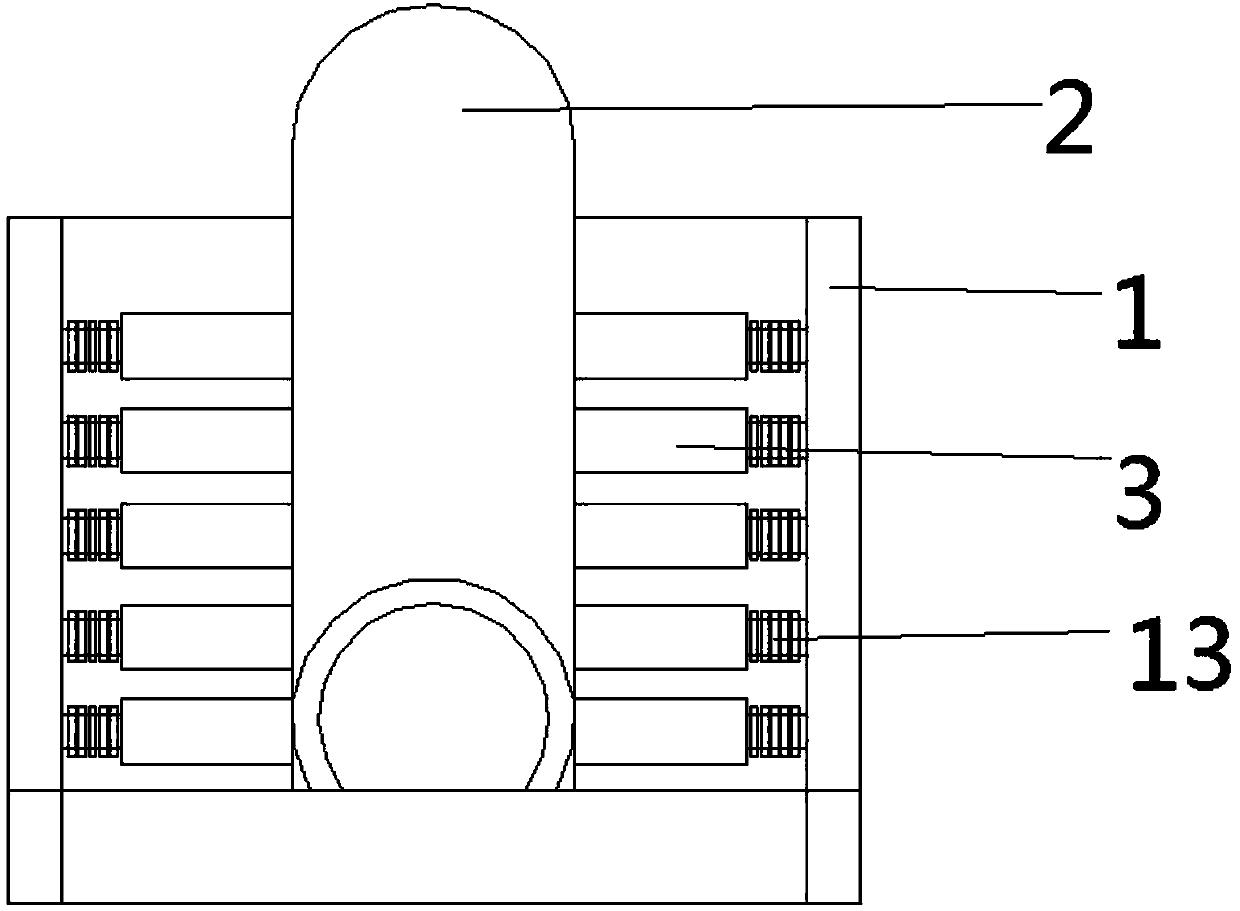

[0013] Such as figure 1 and figure 2 As shown, a squirrel cage prestressed steel bar straightening machine includes a transmission frame 1, a transmission sleeve 2, a transmission roller 3, a first motor 4, a mounting frame 5, a sensor 6, a second motor 7, and a traction roller 8 , rotor 9, electronic flying shears 10, controller 11, bell mouth 12, the transmission frame 1 is installed with the transmission roller 3 through the rotating shaft, the transmission sleeve 2 welded at the middle position of the transmission frame 1 is connected to the bell mouth 12, and the installation frame 5 is installed in sequence The first motor 4 and the second motor 7 are installed, the sensor 6 is installed in the middle position of the first motor 4 and the second motor 7, the rotor 9 built in the first motor 4 and the second motor 7 is equipped with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com