Waterproof flame-retardant covering cloth

A tarpaulin and waterproof layer technology, applied in the field of fabrics, can solve the problem that the tarpaulin is not flame-retardant and sensitive. It can cause combustion when it encounters high temperature and fire, and it may react when it encounters a lot of water vapor. Waterproof effect general questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

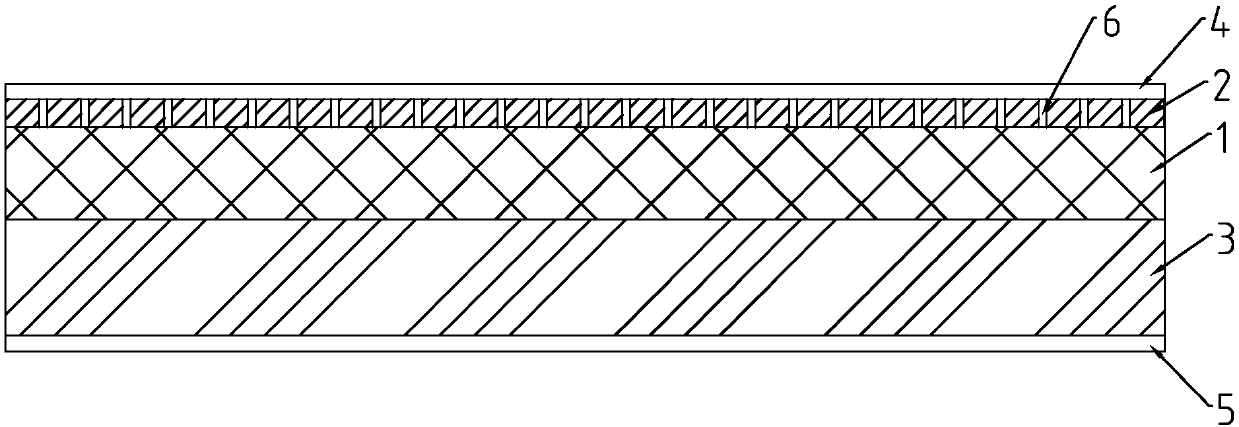

[0019] Such as figure 1 A waterproof and flame-retardant tarpaulin shown includes a base fabric layer 1, the base fabric layer is made of cotton and linen blended fibers, polyester fibers, and spandex, and a waterproof layer 2 is provided on one side of the base fabric layer. The other side of the base fabric layer is provided with a flame retardant layer 3, the side of the waterproof layer facing away from the base fabric layer is provided with a first wear-resistant layer 4, and the side of the flame retardant layer facing away from the base fabric layer is provided with a second wear-resistant layer. Layer 5.

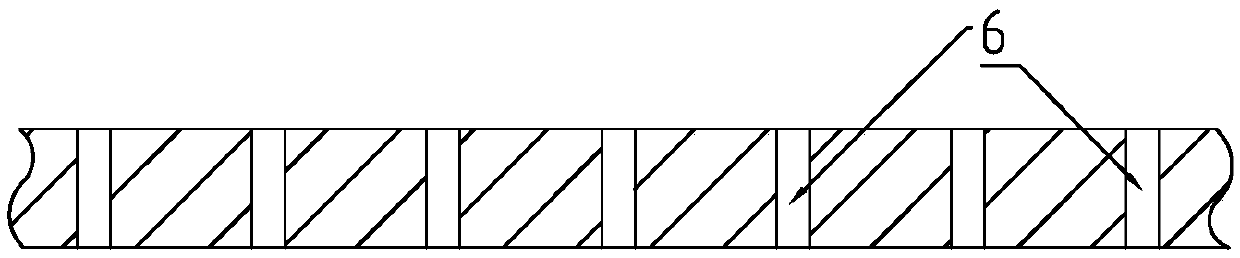

[0020] Such as figure 2 As shown, the waterproof layer is a polyvinyl chloride film layer with a plurality of pores 6 on the surface, and the pores are through holes with a diameter of 0.4um, and the pores are evenly distributed on the surface of the waterproof layer with a spacing of 0.5um. Fine pores can be realized on the waterproof layer by laser, electrochemi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com