A 18-month refueling and loading method for the first-cycle boron-containing core of a pressurized water reactor

A first cycle, pressurized water reactor technology, applied in the 18-month refueling and loading field of the first cycle boron-containing core of the PWR, can solve the problem of short first cycle refueling period, and achieve the goal of reducing the enrichment of components The effect of differentiation, high safety, high economy and operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

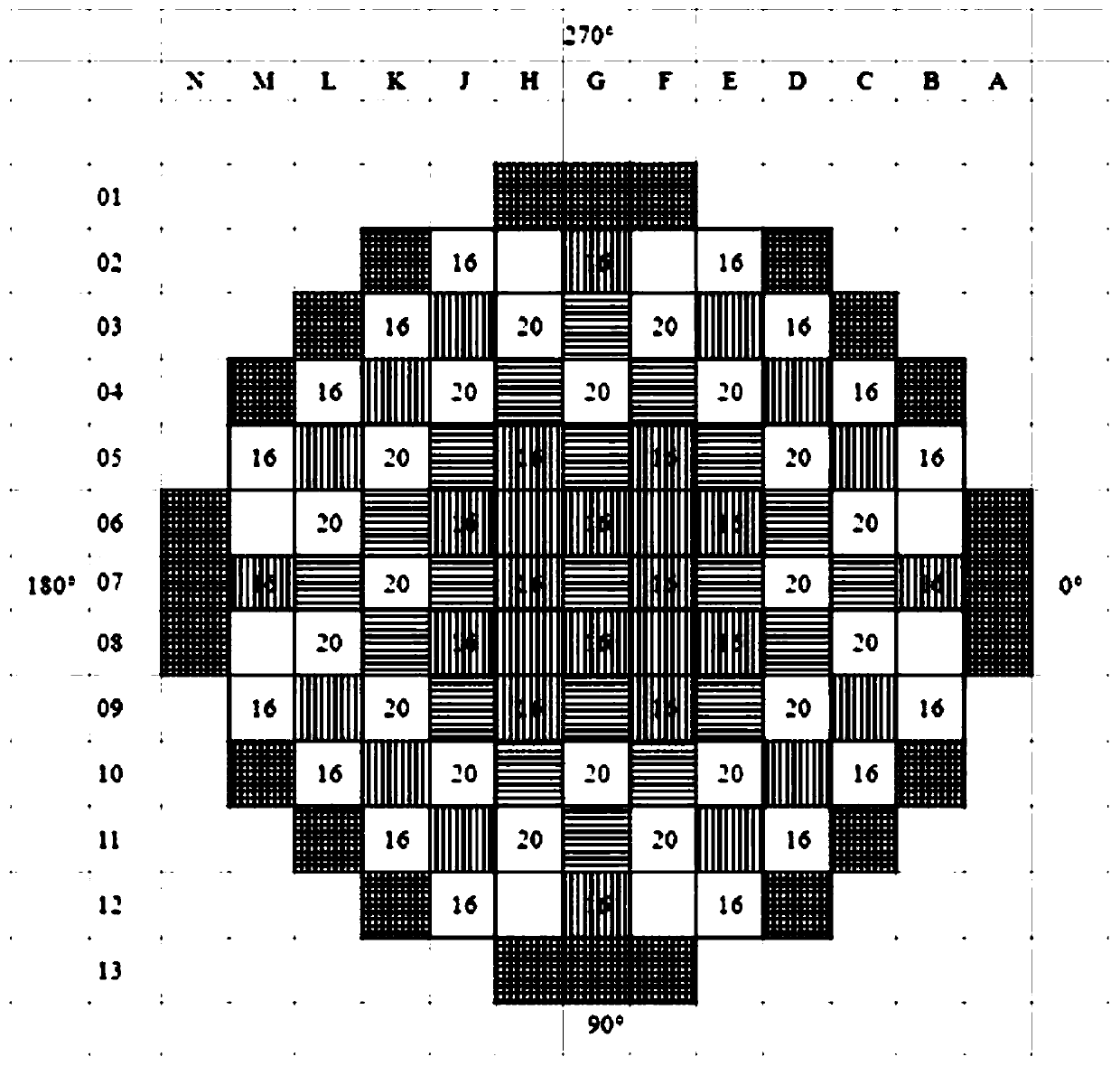

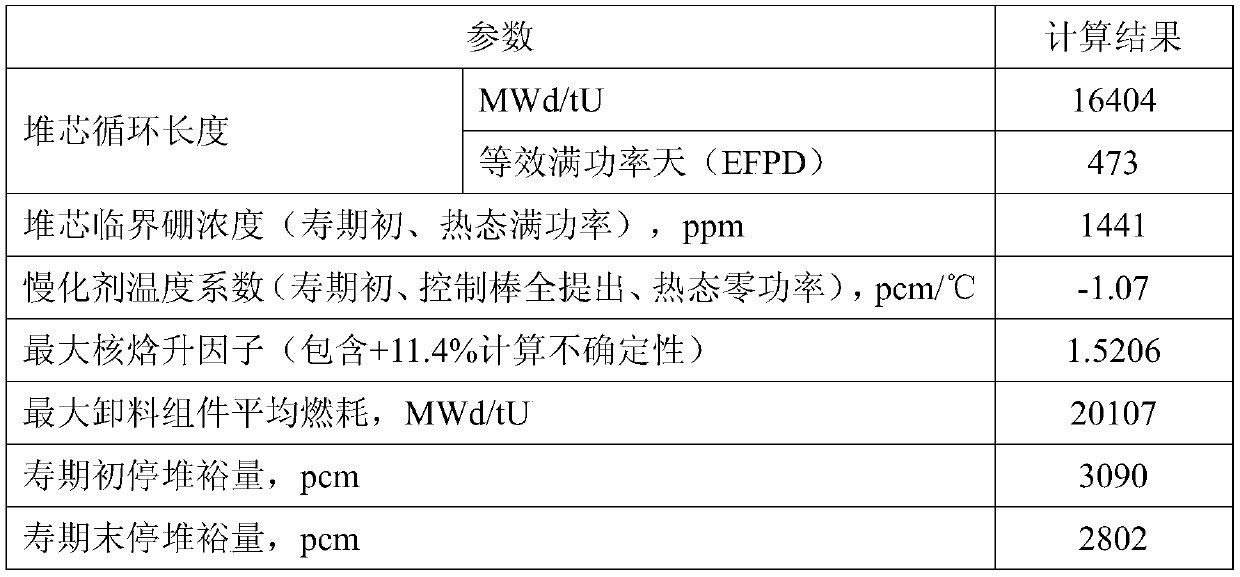

[0025] like figure 1 As shown, an 18-month refueling and loading method for the first-cycle boron-containing core of a PWR. The PWR core is composed of 121 groups of AFA3G fuel assemblies. The diameter is 267.0cm, and the aspect ratio is 1.37. Each AFA 3G fuel assembly consists of 264 fuel rods, 24 zirconium alloy guide tubes and a zirconium alloy gauge tube arranged in a 17×17 square array.

[0026] The first cycle core loading is divided into 4 zones according to the U-235 enrichment degree, and the fuel assemblies with 4 different U-235 enrichment degrees are used, which can better flatten the core power distribution compared with the 3 enrichment degrees ; The U-235 enrichment degrees in Zone 4 are 1.9%, 2.6%, 3.1% and 3.7%, respectively, and the number of fuel assemblies are 21, 32, 44 and 24 groups respectively. Considering that all the fuel assemblies used in the first cycle are new fuel assemblies, In order to effectively flatten the power distribution of the core, a...

Embodiment 2

[0039] This embodiment is based on Example 1, and the number of boron glass rods of the component with an enrichment degree of 2.6% in the embodiment is replaced by 4, or 8 or 20, and the boron glass rods of the component with an enrichment degree of 3.1% The number of glass rods is replaced by 8, or 4 or 24.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com