A method and system for improving the performance of shield cutting tool cemented carbide

A technology of cemented carbide and shield cutting tools, applied in the field of alloys, can solve problems such as insufficient density, reduced hardness and wear resistance, and tool fracture, and achieve the effect of enhancing mechanical properties and thermal conductivity and heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

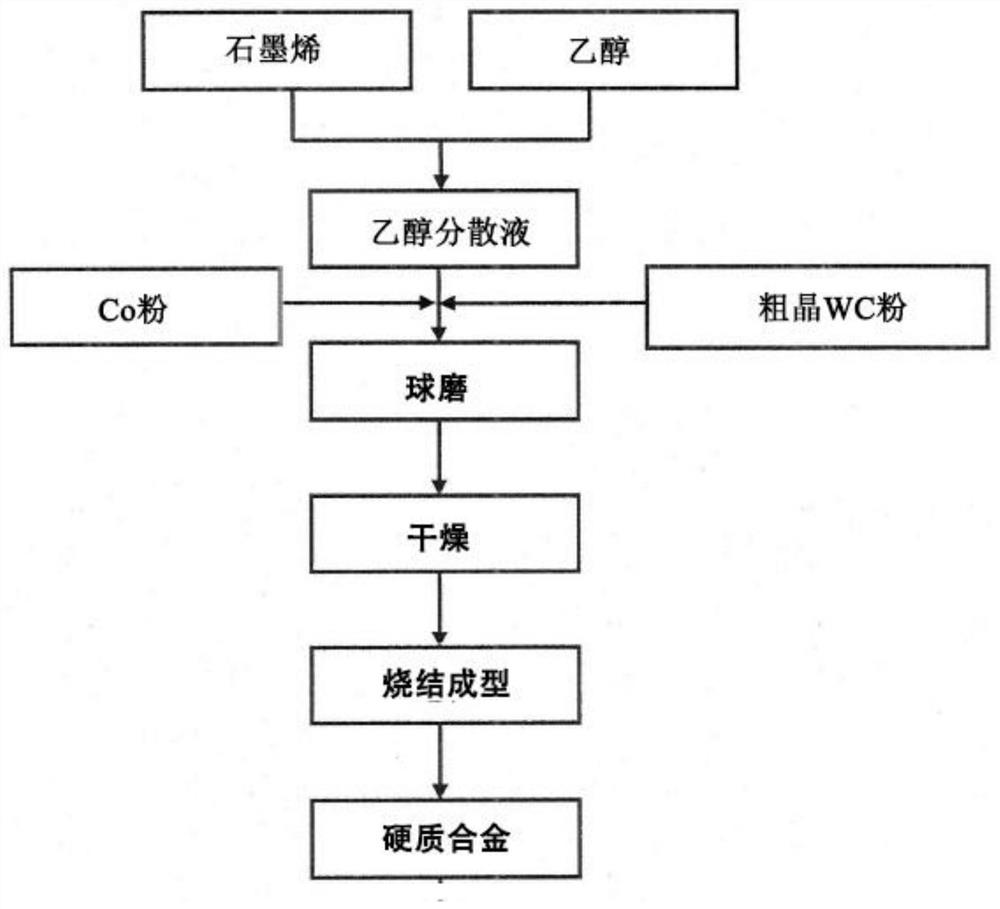

[0053] Implementation case 1 The preparation method of the graphene-doped cemented carbide is:

[0054] Weigh a certain mass of WC and Co powder. The content of Co powder accounts for 6wt% of the alloy raw materials. The graphene of 1% by weight relative to Co is ultrasonically dispersed in ethanol for 30 minutes, and then the ethanol suspension of the graphene is used as The ball milling medium is mixed with WC and Co powder by ball milling, ball milled in a planetary ball mill at 120 rpm for 4 hours, and then vacuum-dried for SPS sintering. The sintering temperature is 1200 degrees Celsius, the axial pressure is 80 MPa, and the heat preservation time is 10 minutes. The furnace is cooled to obtain a cemented carbide doped with graphene. Its performance is shown in Table 1.

Embodiment example 2

[0055] Implementation case 2 The difference between this implementation case and implementation case 1 is that the amount of graphene added is 1.5 wt% of the amount of Co, and its performance is shown in Table 1.

Embodiment example 3

[0056] Implementation case 3 The difference between this implementation case and implementation case 1 is that the amount of graphene added is 2wt% of the amount of Co, and its properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com